Shaft voltage grounding protection structure of traction motor

A grounding protection, traction motor technology, applied in the connection with grounding devices, electrical components, electromechanical devices, etc., can solve the problems of difficult replacement of grounding devices, low space utilization, low product reliability, etc. Space utilization, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

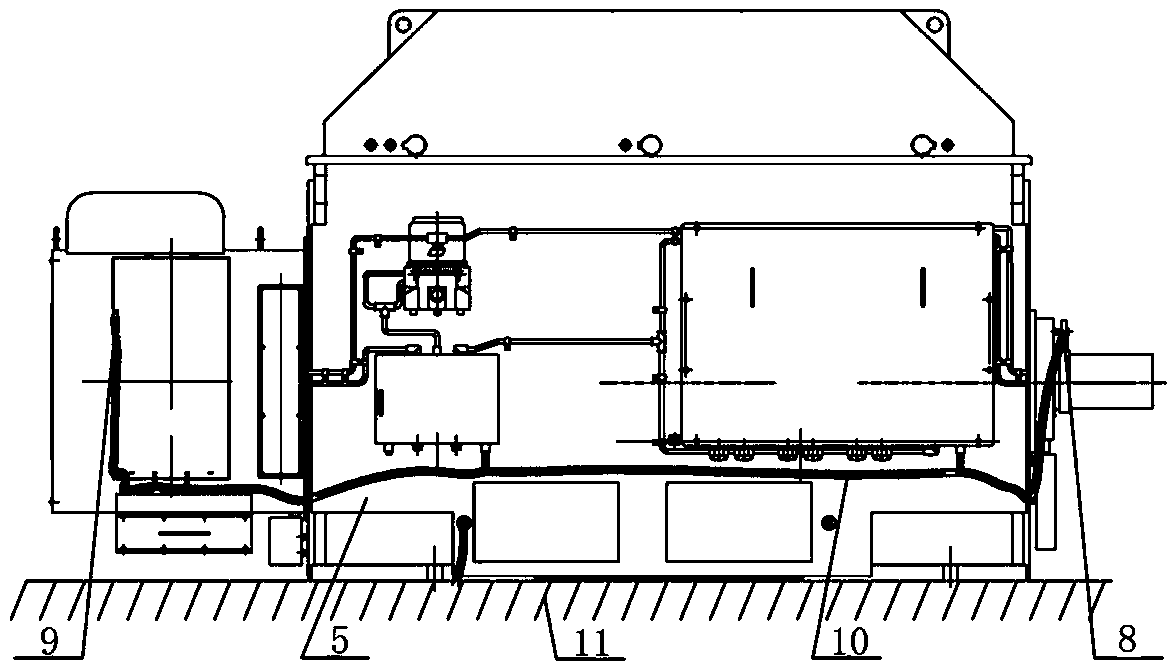

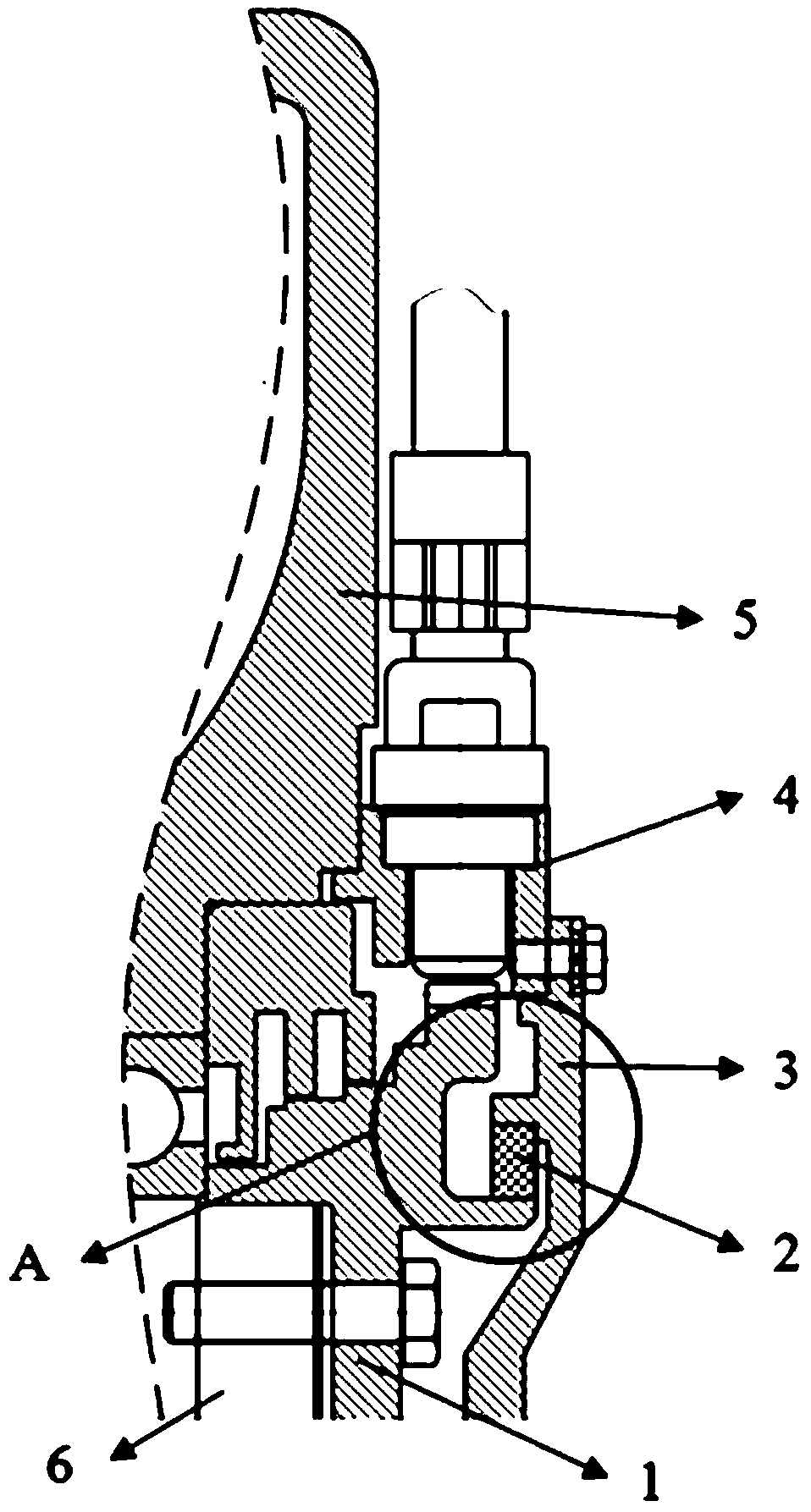

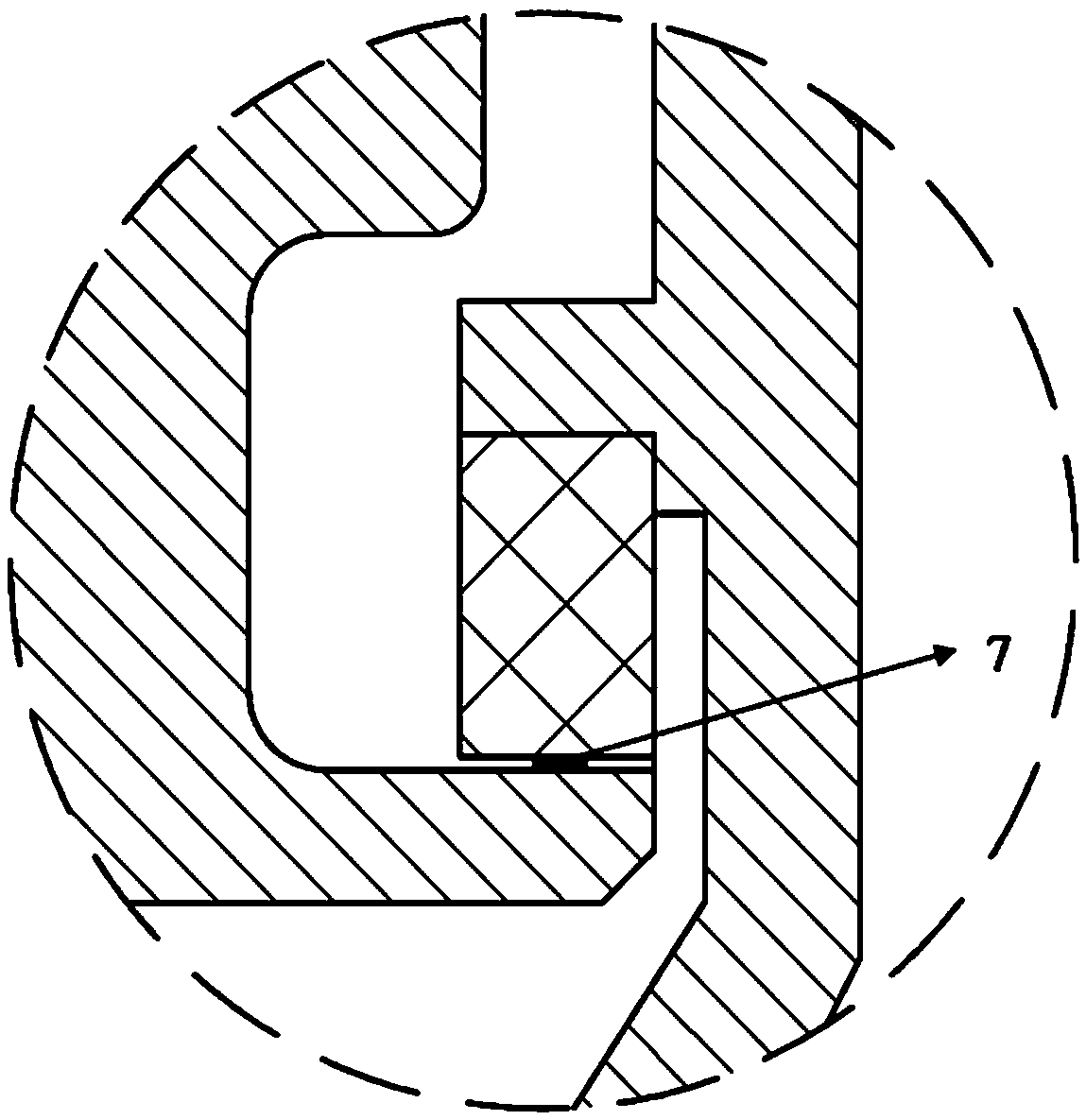

[0025] like figure 2 , image 3 As shown, the present invention includes a speed measuring gear 1, a grounding ring 2, a gear cover cover plate 3, and a gear cover 4. The speed measuring gear 1 is installed on the non-transmission end of the motor shaft 6, and the gear cover 4 is installed on the base shell 5. The gear cover cover plate 3 is installed on the gear cover 4, the grounding ring 2 is installed on the inner side of the gear cover cover plate 3, and the machine base shell 5 is fixed on the train.

[0026] The base shell 5 and the motor shaft 6 are connected to the grounding ring 2, the gear cover cover plate 3 and the gear cover 4 through the annular structure protruding from the speed measuring gear 1, so that they maintain zero potential at the same time and cannot form a current loop, thereby Avoid shaft voltage and shaft current.

[0027] The base shell 5 is connected with the gear cover 4 through conductive metal bolts.

[0028] The gear cover 4 and the gear...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap