Slotted cover device of dissolving equipment

A slot cover and equipment technology, which is applied in the improvement of process efficiency, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problem of harming the health of workers, affecting the recovery of secondary resources, and easily polluting the working environment by overflowing gas. and other problems, to achieve the effect of meeting the requirements of preparation technology and environmental protection, convenient feeding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

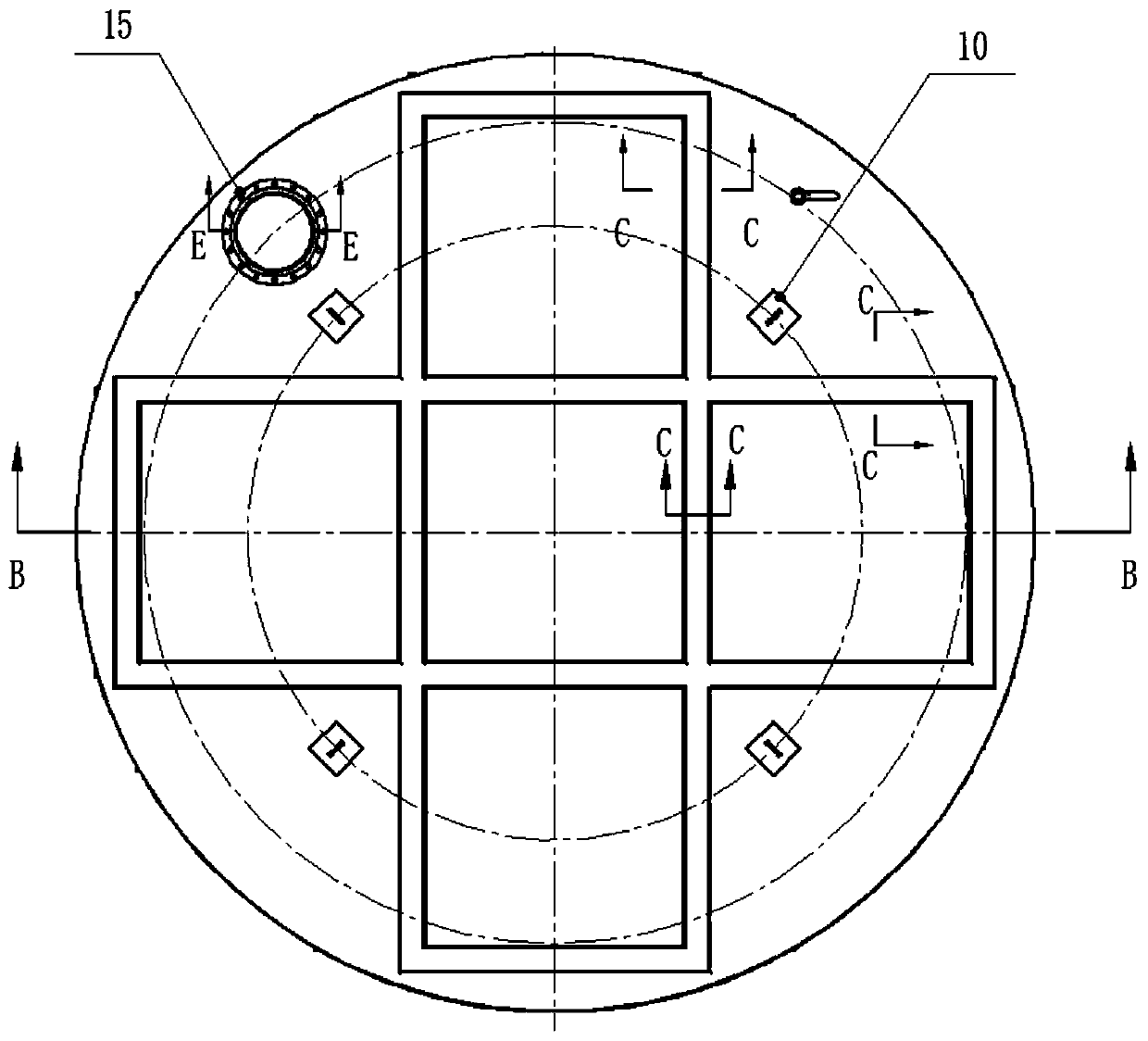

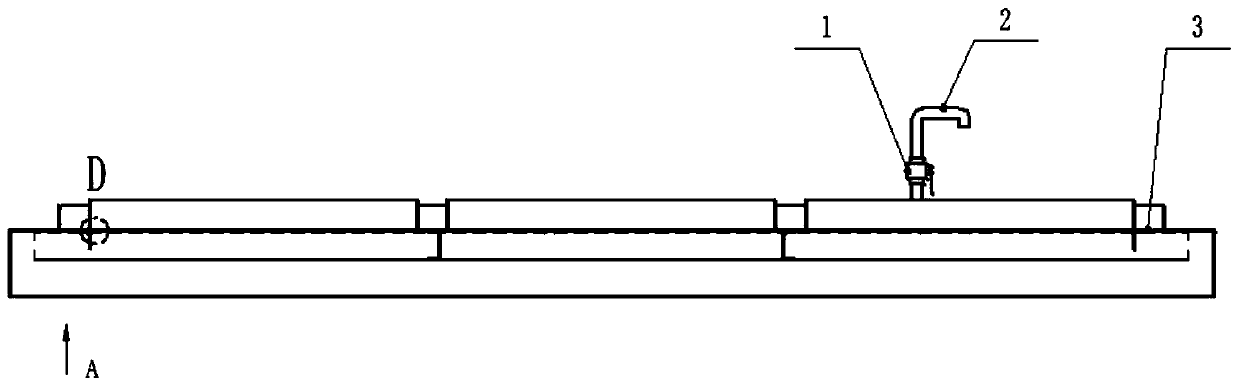

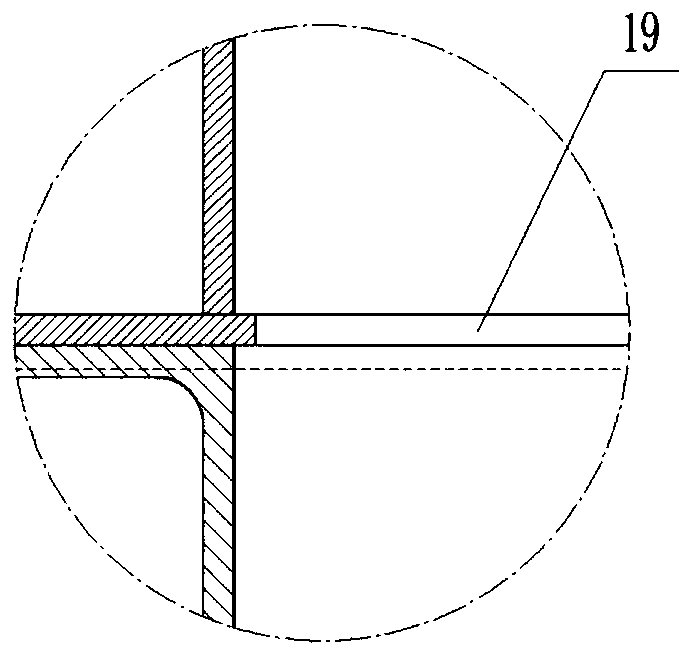

[0023] see Figure 1-10 , the tank cover device of the dissolving equipment, comprising a large tank cover 17 and a small tank cover 18, the large tank cover includes a regulating valve 1, a pipe 2, a circular plate 3, a first angle steel 4, a channel steel 5, a second angle steel 6, Lifting lug 10, inner groove plate 11, exhaust hole 15, outer groove plate 16, feeding hole 19, side plate 20, etc. The small slot cover includes a top plate 21, a lifting lug 10, an outer insert plate 22, an inner insert plate 23, a first plate 24, a second plate 25, and the like. Five feeding holes 19 are evenly distributed on the circular plate 3, and there is a square bar-shaped water tank around the hole, and the inner groove plate 11 is higher than the outer groove plate 16; A small groove cover 18 is arranged on the feeding hole 19, and its outer insert plate 22 is immersed in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com