A one-stop fully automatic bms intelligent test system

A testing system and fully automatic technology, applied in the direction of testing electrical devices, measuring electricity, and measuring devices in transportation, can solve the problems of low production capacity and low testing efficiency, and achieve the effects of good flexibility, labor saving, and high testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

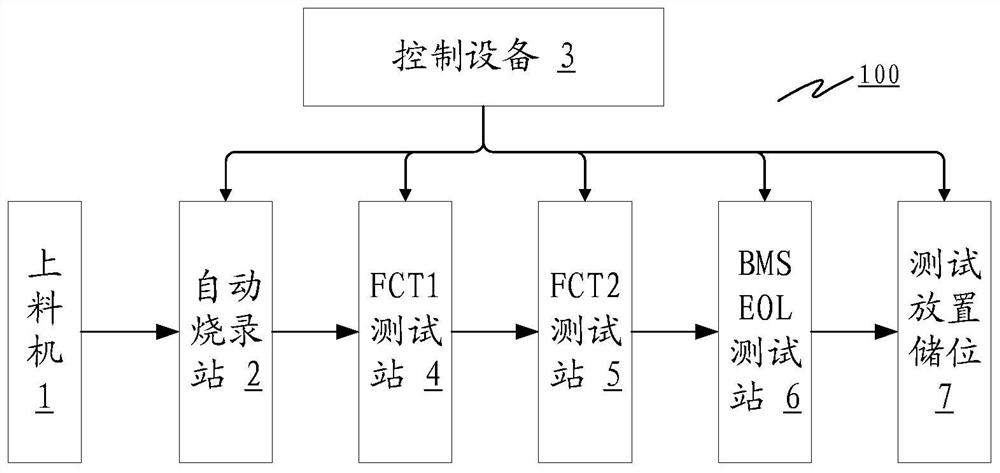

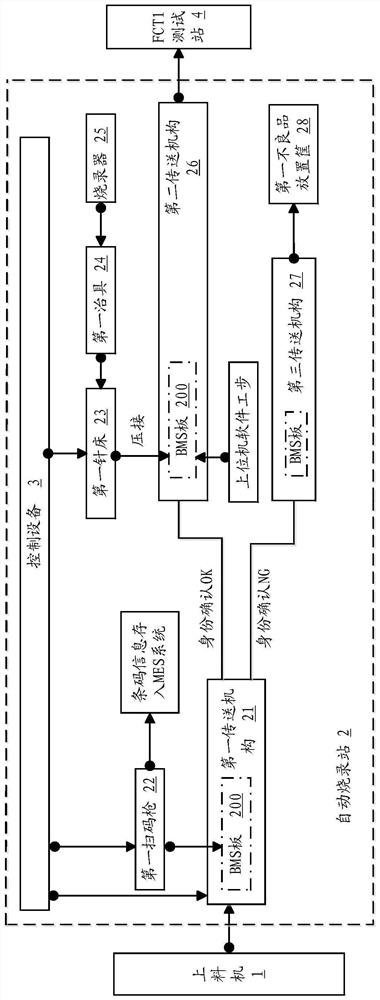

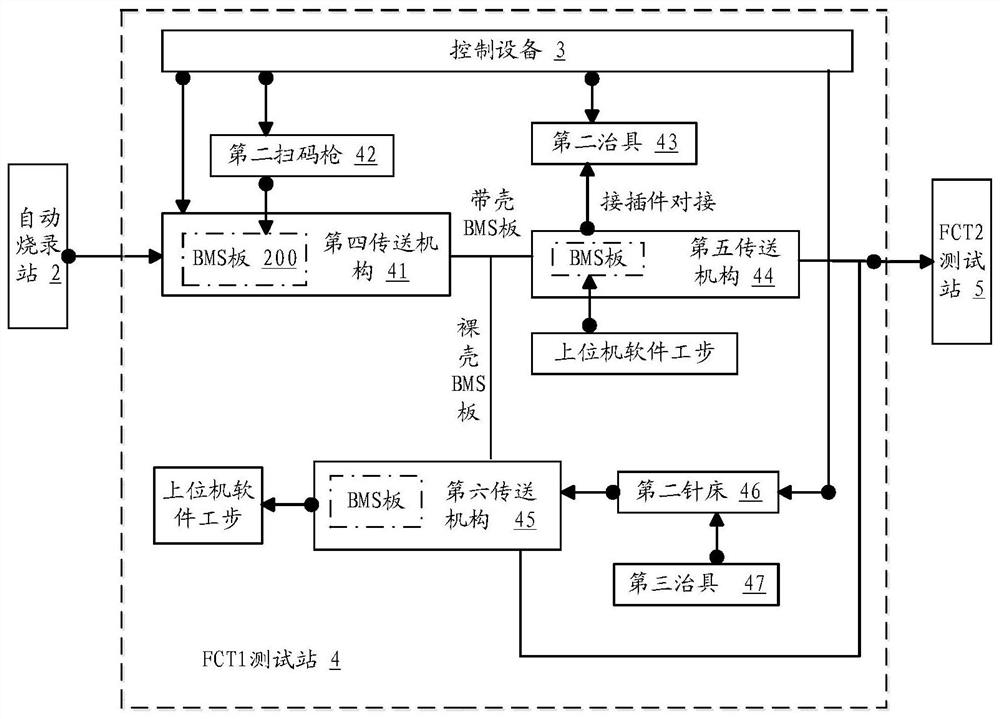

[0040] see Figure 1 to Figure 6 As shown, a preferred embodiment of a one-stop fully automatic BMS intelligent test system 100 of the present invention, the test system 100 includes a feeder 1, an automatic programming station 2, a control device 3 (such as PLC control device), a FCT1 test station 4, a FCT2 test station 5, a BMS EOL test station 6 and a test product placement storage position 7; the loading machine 1, automatic programming station 2, FCT1 test station 4, FCT2 test Both the station 5 and the BMS EOL test station 6 are controlled by the control device 3;

[0041] The automatic programming station 2 is set at the front end of the loading machine 1, and the BMS board 200 to be tested is transmitted to the automatic programming station 2 through the loading machine 1 for programming. , the feeder 1 can automatically grab the BMS board 200 to be tested from the tray, and place it on the FCT1 test station 4; the FCT1 test station 4 is located at the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com