Special waterproof coating for roads and bridges, and preparation method thereof

A waterproof coating, road and bridge technology, used in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., can solve problems such as personal safety hazards, inconvenience in life, property damage, etc., achieving a high degree of automation and no materials. Toxic and non-polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

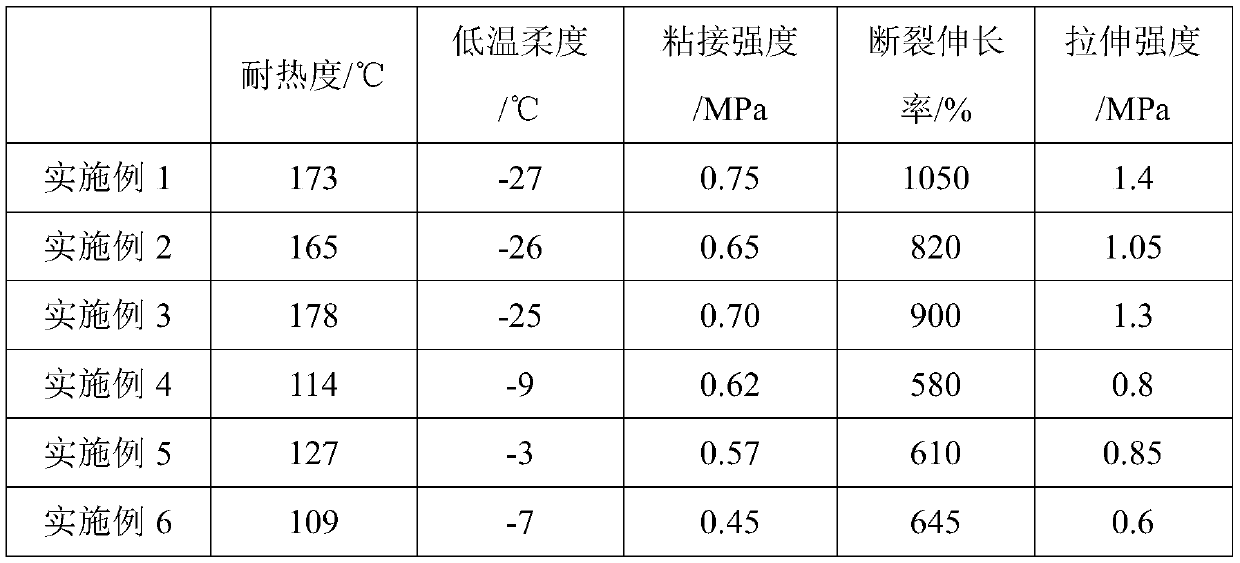

Examples

preparation example Construction

[0051] Among the present invention, the preparation method of described cationic emulsified bitumen at least comprises the following steps:

[0052] (1) Preparation of cationic emulsifier: heat water to 40-60°C with stirring, then add lignin and inorganic base, continue to stir and heat to 70-80°C, react for 2-4h, and discharge to obtain the product;

[0053] (2) Preparation of cationic emulsified asphalt: mix the cationic emulsified asphalt prepared in step (1) with water, heat to 60-70°C while stirring, then add asphalt, continue to stir and heat to 80-90°C, and the discharge is ready have to.

[0054] Preferably, in the step (1), the inorganic base is at least one selected from sodium hydroxide, magnesium hydroxide, magnesium hydroxide and aluminum hydroxide.

[0055] As a preference, in the step (1), the weight ratio of water, lignin and inorganic base is 1:(1.9-2.1):(0.3-0.4).

[0056] As a preference, in the step (2), the weight ratio of the cationic emulsifier to the as...

Embodiment 1

[0079] Embodiment 1 provides a special waterproof coating for roads and bridges, which includes the following components by weight percentage: 25% neoprene latex, 15% styrene-butadiene latex, 50% asphalt, 6% water, and 4% additives.

[0080] The chloroprene latex has a solid content of 50 wt% and a dynamic viscosity of 18 mPa·s, purchased from Shanxi Huochangchang Chemical Synthetic Rubber Co., Ltd., model: CRL50LF.

[0081] The dynamic viscosity of the styrene-butadiene latex at 25° C. is lower than 100 mPa·s; the pH value is 4-6, purchased from but not limited to Shandong Qiaolong Environmental Protection Technology Co., Ltd., model: Cationic 50.

[0082] The asphalt is cationic emulsified asphalt, C 25,3 Standard viscosity is 12s; The preparation method of described cationic emulsified bitumen comprises the following steps:

[0083] (1) Preparation of cationic emulsifier: heat 100Kg of water to 50°C with stirring, then add 200Kg of lignin and 35Kg of sodium hydroxide, cont...

Embodiment 2

[0092] Embodiment 2 provides a special waterproof coating for roads and bridges, including the following components by weight percentage: 20% neoprene latex, 10% styrene-butadiene latex, 60% asphalt, 5% water, and 5% additives.

[0093] The chloroprene latex has a solid content of 50 wt% and a dynamic viscosity of 18 mPa·s, purchased from Shanxi Huochangchang Chemical Synthetic Rubber Co., Ltd., model: CRL50LF.

[0094] The dynamic viscosity of the styrene-butadiene latex at 25° C. is lower than 100 mPa·s; the pH value is 4-6, purchased from but not limited to Shandong Qiaolong Environmental Protection Technology Co., Ltd., model: Cationic 50.

[0095] The asphalt is cationic emulsified asphalt, C 25,3 Standard viscosity is 12s; The preparation method of described cationic emulsified bitumen comprises the following steps:

[0096] (1) Preparation of cationic emulsifier: heat 100Kg of water to 50°C with stirring, then add 200Kg of lignin and 35Kg of sodium hydroxide, continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com