Battery pack circuit resistance monitoring device and method

A battery pack and circuit resistance technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve problems that affect the normal power supply of the entire battery pack, cannot effectively detect the resistance of the connecting strip, and consume a lot of time, manpower, and material resources. Achieve the effect of long-term history tracking, easy application and promotion, and prevention of abnormal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

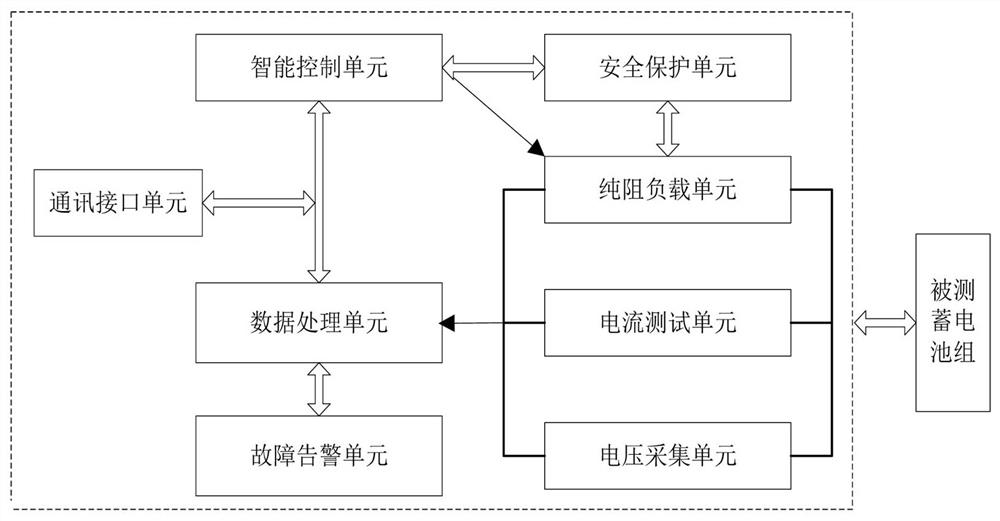

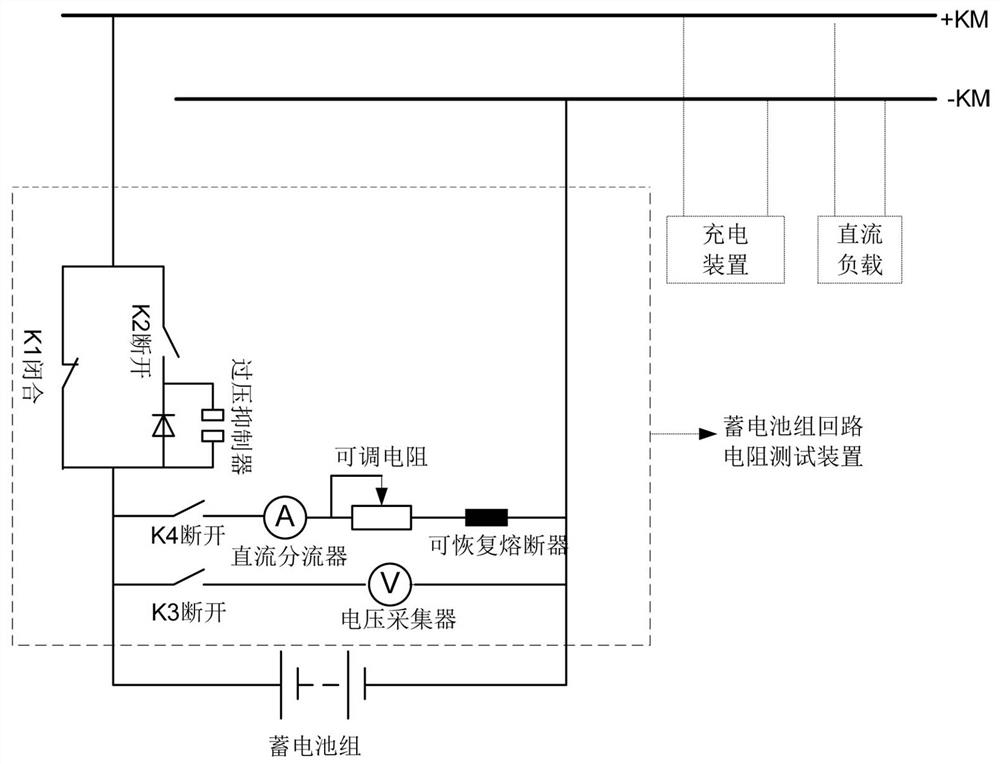

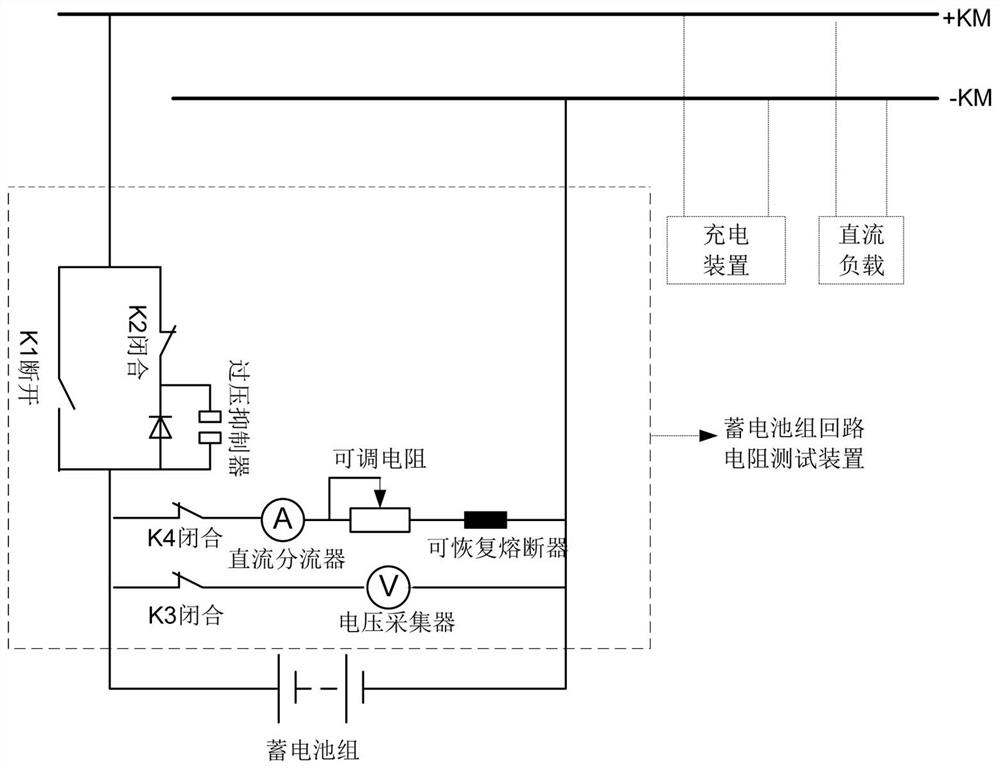

[0058] Based on the above design idea, in one of the specific limited solutions of the present invention, the battery pack loop resistance monitoring device (such as figure 1 shown) including intelligent control unit, voltage acquisition unit, current test unit, pure resistance load unit, data processing unit, fault alarm unit, safety protection unit, and communication interface unit. like figure 1 As shown, specifically, the intelligent control unit is used to set the test parameters of the circuit resistance of the battery pack, and to start or terminate the battery pack test circuit. Specifically in this embodiment, its main function is to realize the regular start-up test of the battery pack circuit resistance monitoring device by controlling the opening and closing of the switch. Preferably, the test time and test interval time of each battery pack loop resistance test can be set, so as to realize the online timing test of the battery pack loop resistance, and the long-t...

Embodiment 2

[0072] This embodiment relates to a method for monitoring the circuit resistance of a battery pack, which is a specific application of Embodiment 1. One of the implementations such as Figure 4 shown. Depend on Figure 4 It can be seen that the method for monitoring the circuit resistance of the battery pack includes the following steps:

[0073] Step 1: Setting of the battery pack circuit resistance test device

[0074] Connect the battery pack loop resistance monitoring device to the battery pack outlet, and set the time interval and single test time for the self-starting test of the battery pack loop resistance monitoring device, as well as the over-limit alarm limit, etc. Specifically in this embodiment, when the test result of the circuit resistance of the battery pack increases by 50% or more compared with the historical value, an alarm should be issued immediately. If the device self-start test time is not reached at this time, the test will not be started. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com