Dairy product fermentation tank

A technology for fermentation tanks and dairy products, which is applied in the field of fermentation tanks, can solve the problems that the structure cannot have redundant tortuous structures, the fermentation tank cannot have too many accessories, and the effect may not meet the requirements, so as to achieve a simple structure, reduce the existence and possibility of dead ends and the like. , the idea of novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

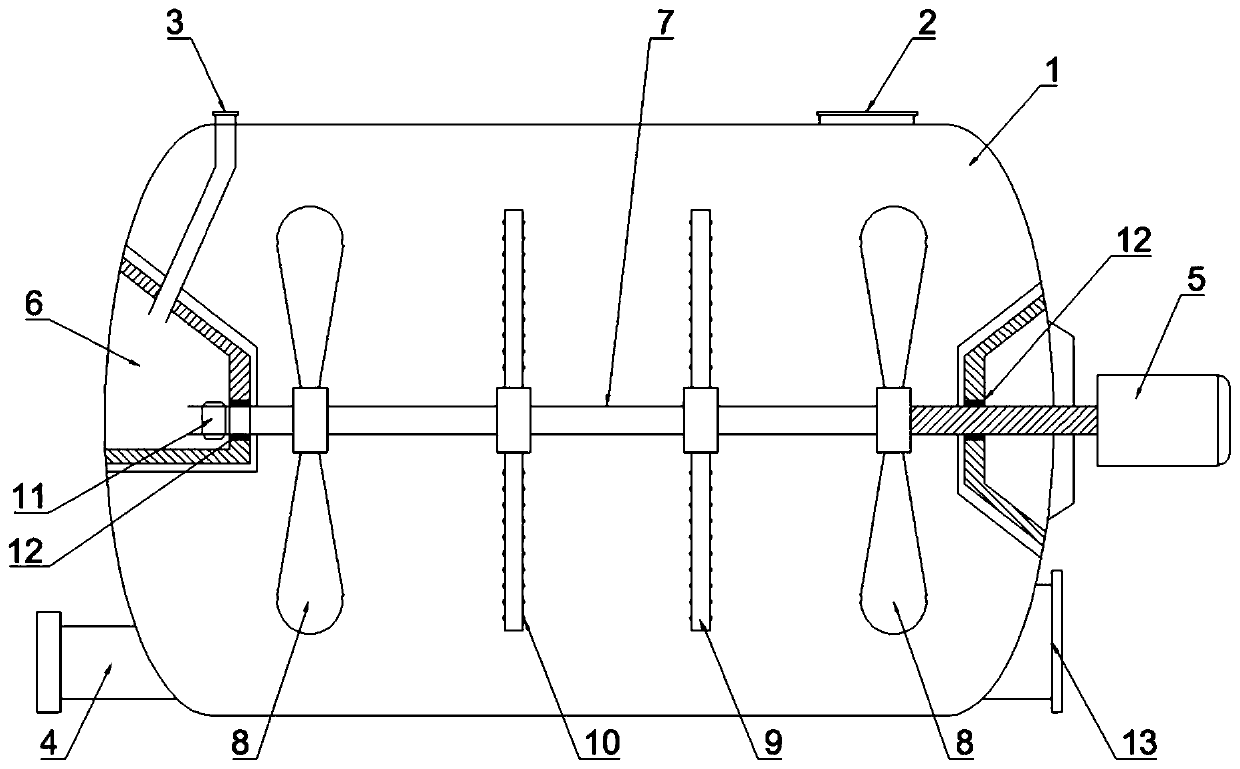

[0016] see figure 1 The dairy fermenter shown includes a horizontal tank body 1, the upper part of the tank body 1 is provided with a main feed port 2 and a secondary feed port 3, and the lower part of the tank body 1 is provided with a discharge port 4 and a manhole 13. A stirring shaft 7 runs through the body 1 transversely. One end of the stirring shaft 7 is connected to a motor 5, and the other end is located in the tank body 1 of the fermenter and communicated with a liquid storage chamber 6. The liquid storage chamber 6 is located in the tank body 1 relative to the motor. At the other end of 5, the liquid storage chamber 6 communicates with the auxiliary feed port 3 through a pipeline. The stirring shaft 7 is provided with a spoiler vane 8 and a liquid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com