Pure-bolt-connection pulse bag type dust collector

A bag-type dust collector and pulse technology, applied in the field of protective devices, can solve the problems of component design size, stability, fatigue strength, aesthetics, anti-corrosion effect, unfavorable maintenance and product upgrades, consumption of manpower and material resources, etc. To achieve the effect of removing the painting process, avoiding deformation, and facilitating the replacement of filter bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

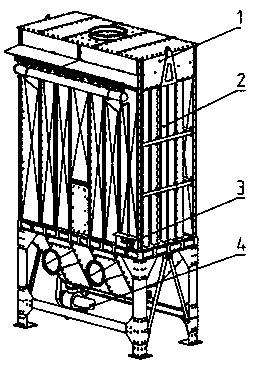

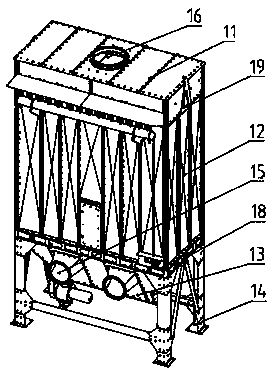

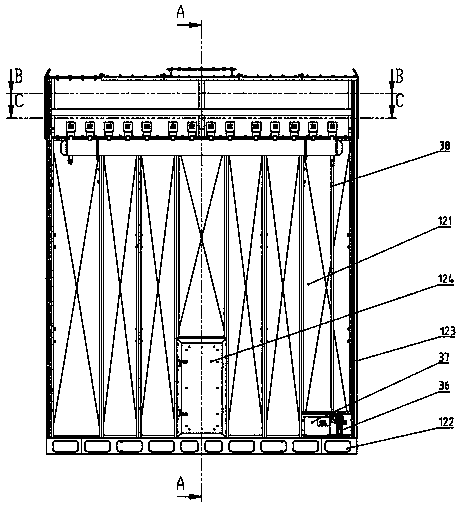

[0047] Such as Figure 1-19 As shown, a purely bolt-connected pulse bag filter includes a frame shell 1, a filter bag assembly 2, a blowing soot cleaning device 3 and ash discharge device 4, and the inside of the frame shell 1 is provided with a filter bag assembly into 2 and ash discharge device 4, and a blowing ash removal device 3 is provided on the outside;

[0048]The frame shell 1 includes an upper box body 11, a lower box body 12, an ash hopper 13, a bracket 14, an air inlet 15, an air outlet 16, an air flow partition 17, a connecting ring beam 18 and a hoisting plate 19; it is arranged inside the lower box body 12 The filter bag assembly 2 is used to support the filter bag, and make the filter bag tense and maintain a certain shape in the state of filtering and dust removal, so as to reduce the damage of the filter bag. The filter ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com