Ceramic chopper

A rivet and ceramic technology, applied in the field of ceramic rivets, can solve the problem that the tip is not directional, and achieve the effects of reducing the degree of gold retention at the tip, improving stability and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

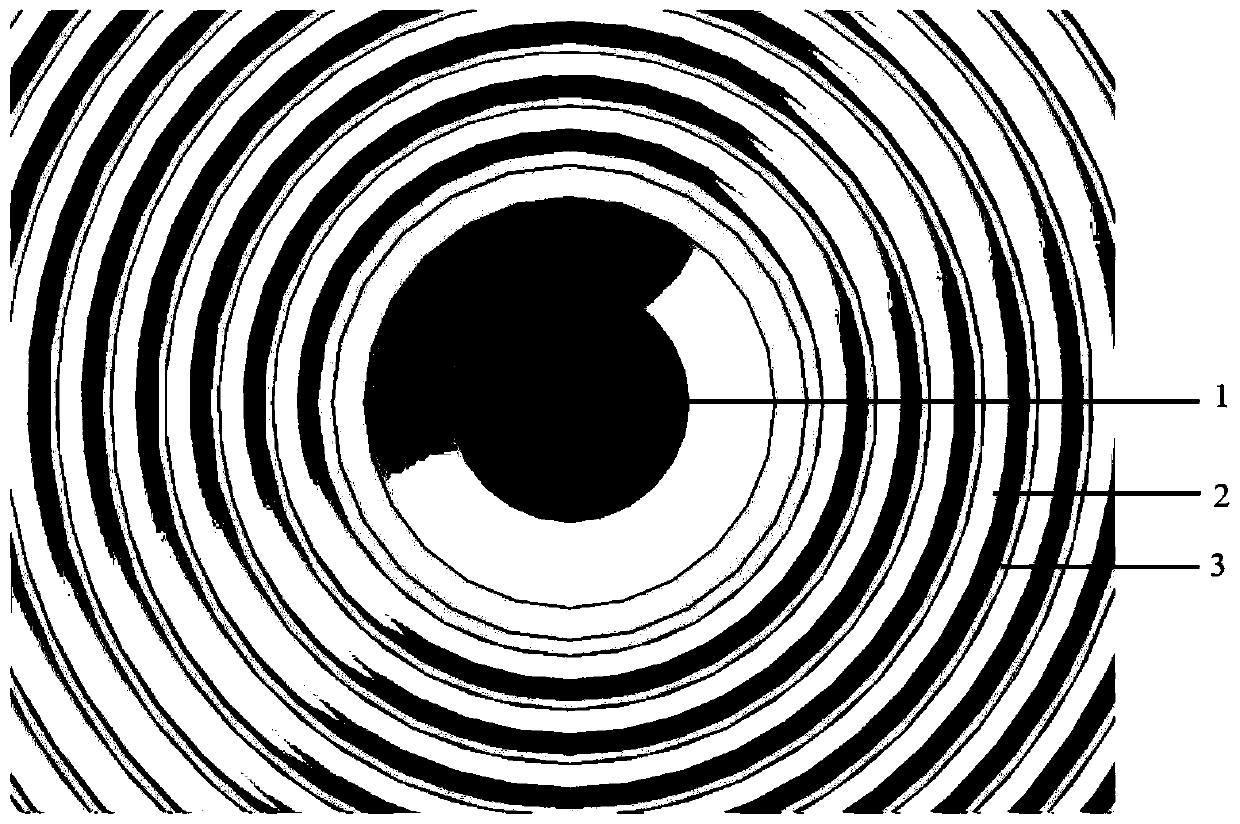

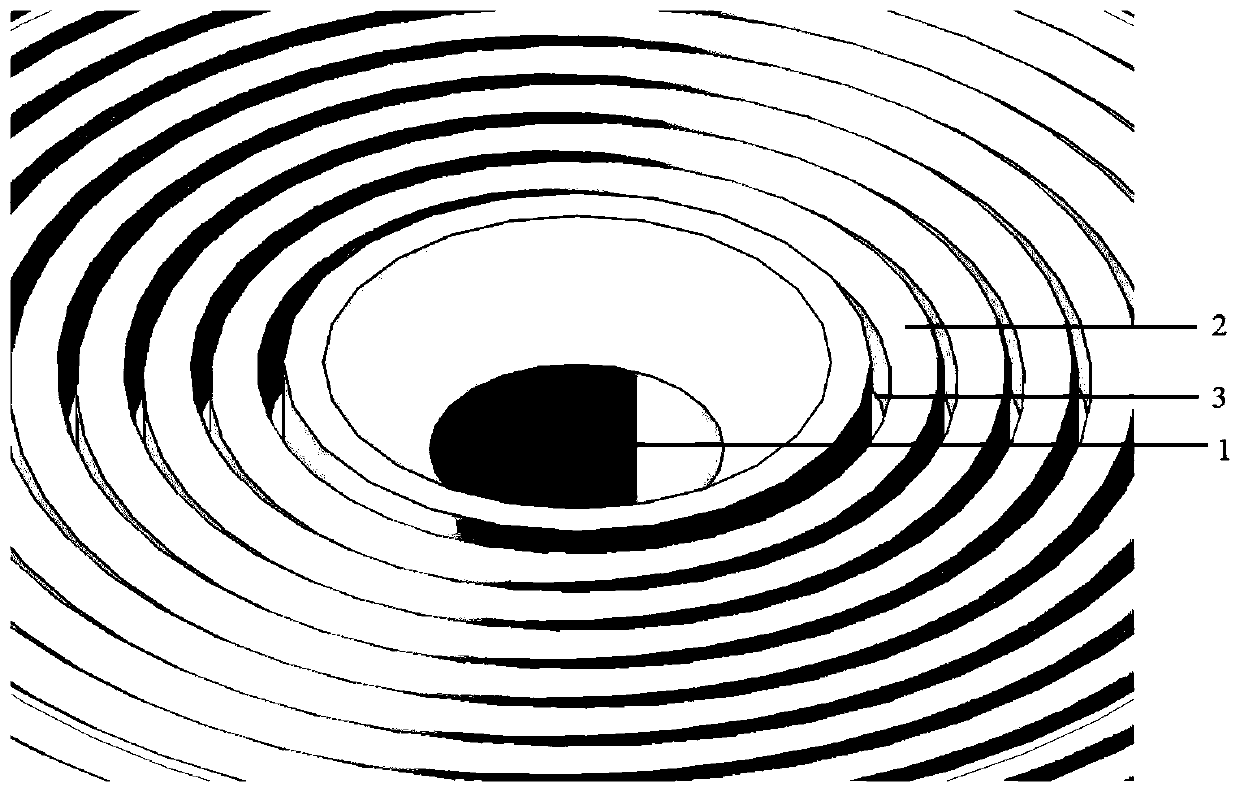

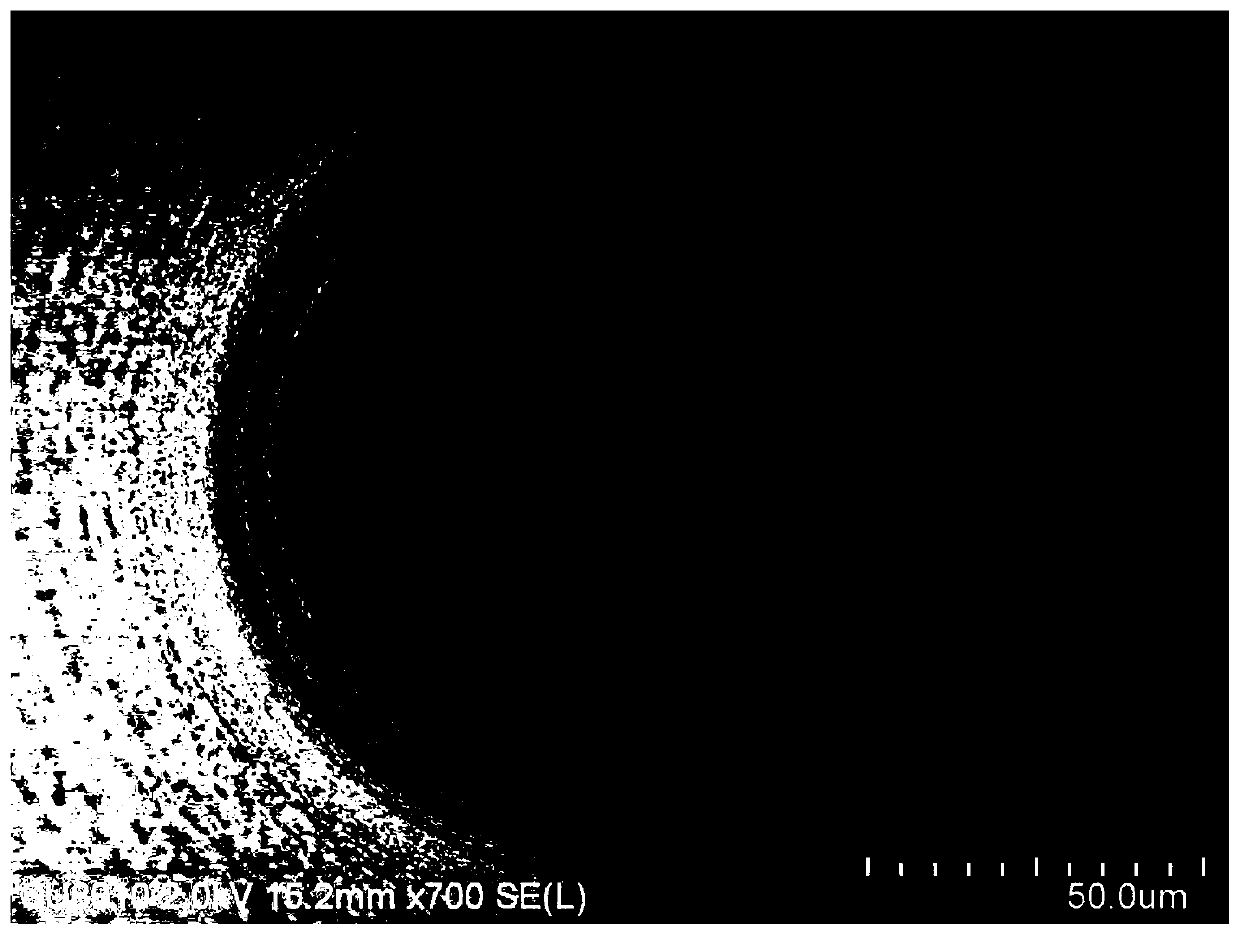

[0042] As an embodiment of the ceramic rivet of the present invention, the ceramic rivet of this embodiment includes a body, a welding tip located at one end of the body and a hole, the hole extends along the longitudinal axis of the body and the welding tip, and the tip of the welding tip surface as Figure 1-2As shown, there is a multi-level concentric ring with the geometric center of the welding tip as the center. The multi-level concentric ring is arranged in concave and convex alternately, and the highest point of the convex concentric ring in the multi-level concentric ring and the concave concentric circle The lowest point of the ring forms a height difference, and the height difference is 6 μm; each convex concentric ring is composed of independently arranged ring protrusions, and the height of each ring protrusion is the same; each convex concentric ring The widths are all the same, and the width of the convex concentric rings is 3 μm; the width of each concave conce...

Embodiment 2

[0047] The ceramic rivet of the present embodiment is basically the same as that of Embodiment 1, the difference is that the highest point of the convex concentric ring and the lowest point of the concave concentric ring in the multi-stage concentric ring of the ceramic rivet of the present embodiment form a height difference, The height difference is 10 μm.

Embodiment 3

[0049] The ceramic rivet of the present embodiment is basically the same as that of Embodiment 1, the difference is that the highest point of the convex concentric ring and the lowest point of the concave concentric ring in the multi-stage concentric ring of the ceramic rivet of the present embodiment form a height difference, The height difference is 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com