OLED organic vacuum evaporation equipment anti-adhesion plate cleaning agent and applications thereof

A board cleaning agent, cleaning agent technology, applied in the direction of organic non-surface active cleaning composition, detergent composition, cleaning method and utensils, etc., can solve the problems that there is no such cleaning agent, and achieve thorough cleaning effect and use Low cost and low corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

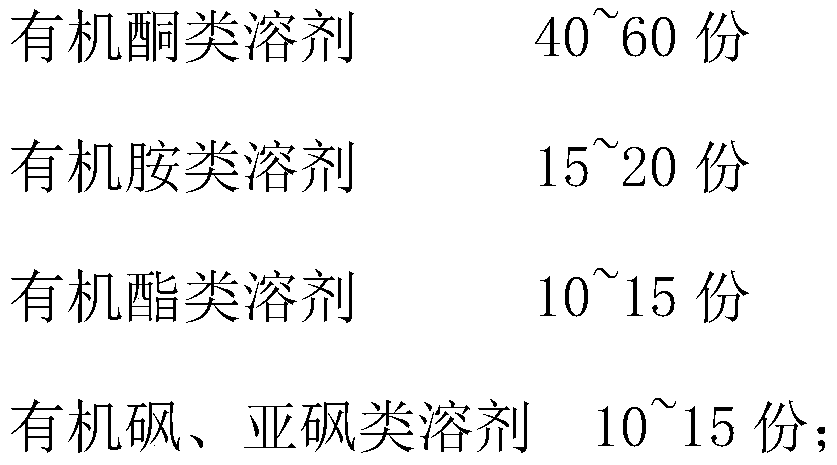

[0042] A preparation method of a cleaning agent for an anti-sticking plate of OLED organic evaporation equipment, comprising:

[0043] According to the parts by weight in claim 2, various components are added into the stirred tank successively, wherein the stirring speed is controlled at 30 ~ 50 rpm, cooling water is used in the jacket of the stirred tank, and the temperature is controlled below 40 degrees. The cleaning agent was prepared after stirring slowly at room temperature for 30 minutes.

[0044] Application of a cleaning agent for the anti-sticking board of OLED organic evaporation equipment. Under the condition of temperature 40-60°C, soak the anti-sticking board of organic evaporation equipment in the cleaning agent for 30-60 minutes to remove the surface of the anti-sticking board organic pollutants; the temperature is 50°C; the soaking time is 60min.

Embodiment

[0046] Take 55kg of N-methylpyrrolidone, 15kg of N,N-dimethylformamide, 5kg of monoethanolamine, 15kg of ethyl acetate, and 10kg of dimethyl sulfone, and add them to the stirring tank in sequence, wherein the stirring speed is controlled at 30 rpm, stirring Cooling water is used in the kettle jacket, the temperature is controlled below 40 degrees, and the cleaning agent is prepared after stirring slowly at room temperature for 30 minutes.

[0047] Under the condition of 60°C, use the cleaning agent of the above ingredients to soak the anti-sticking plate of the evaporation equipment for 60 minutes, so that the organic pollutants are completely removed. Observation by the microscopic ultraviolet lamp shows that there are no visible pollutants on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com