Automobile single-arm type four-connecting-rod glass lifter

A technology of glass lifter and four-linkage, which is applied in door/window fittings, buildings, and wing leaf control mechanisms, etc. It can solve problems such as hindering the movement of parts, glass jamming, and increased system resistance, and achieves reduction Noisy, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

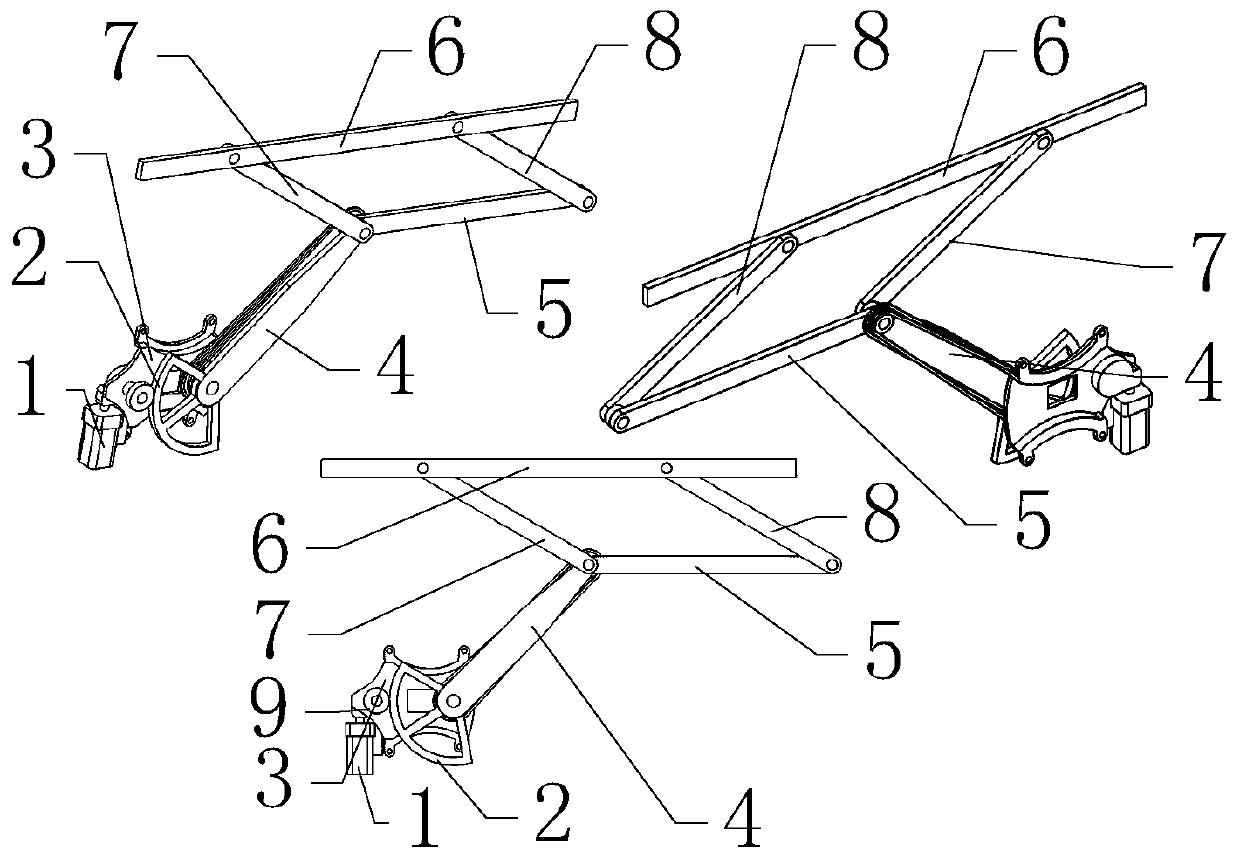

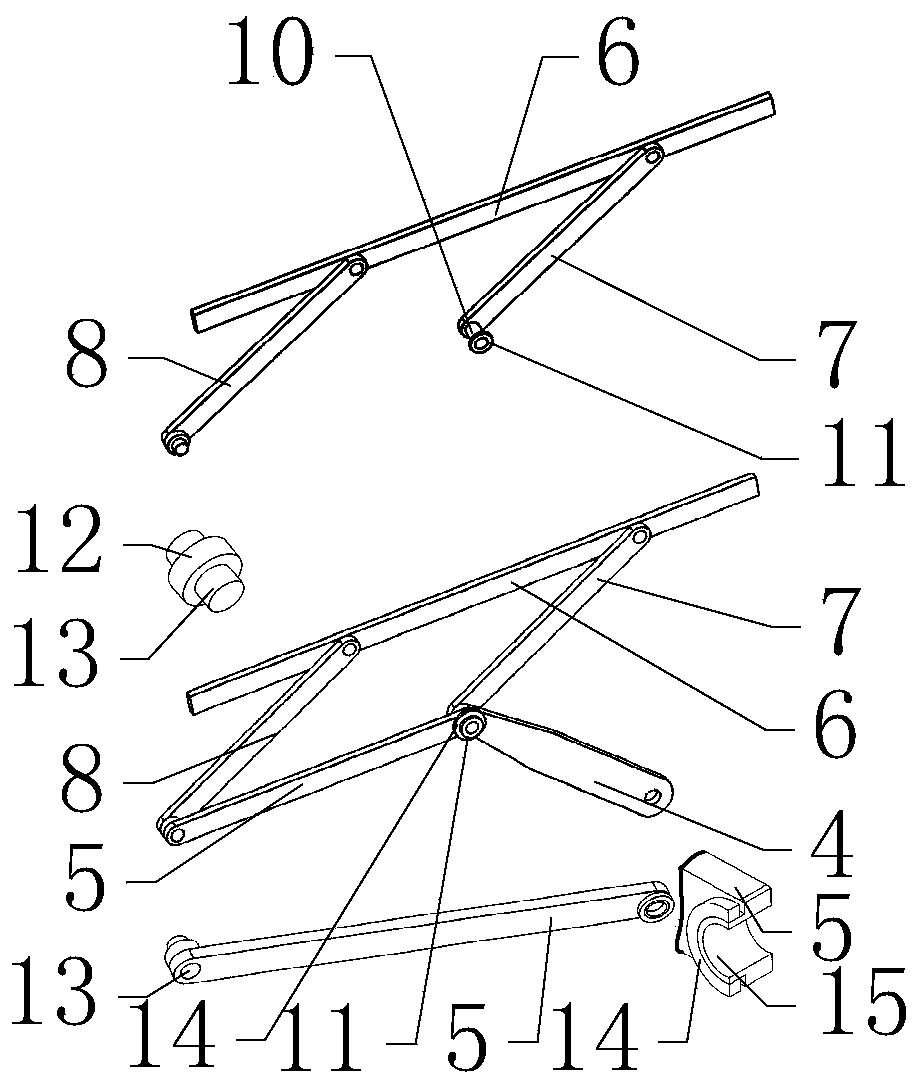

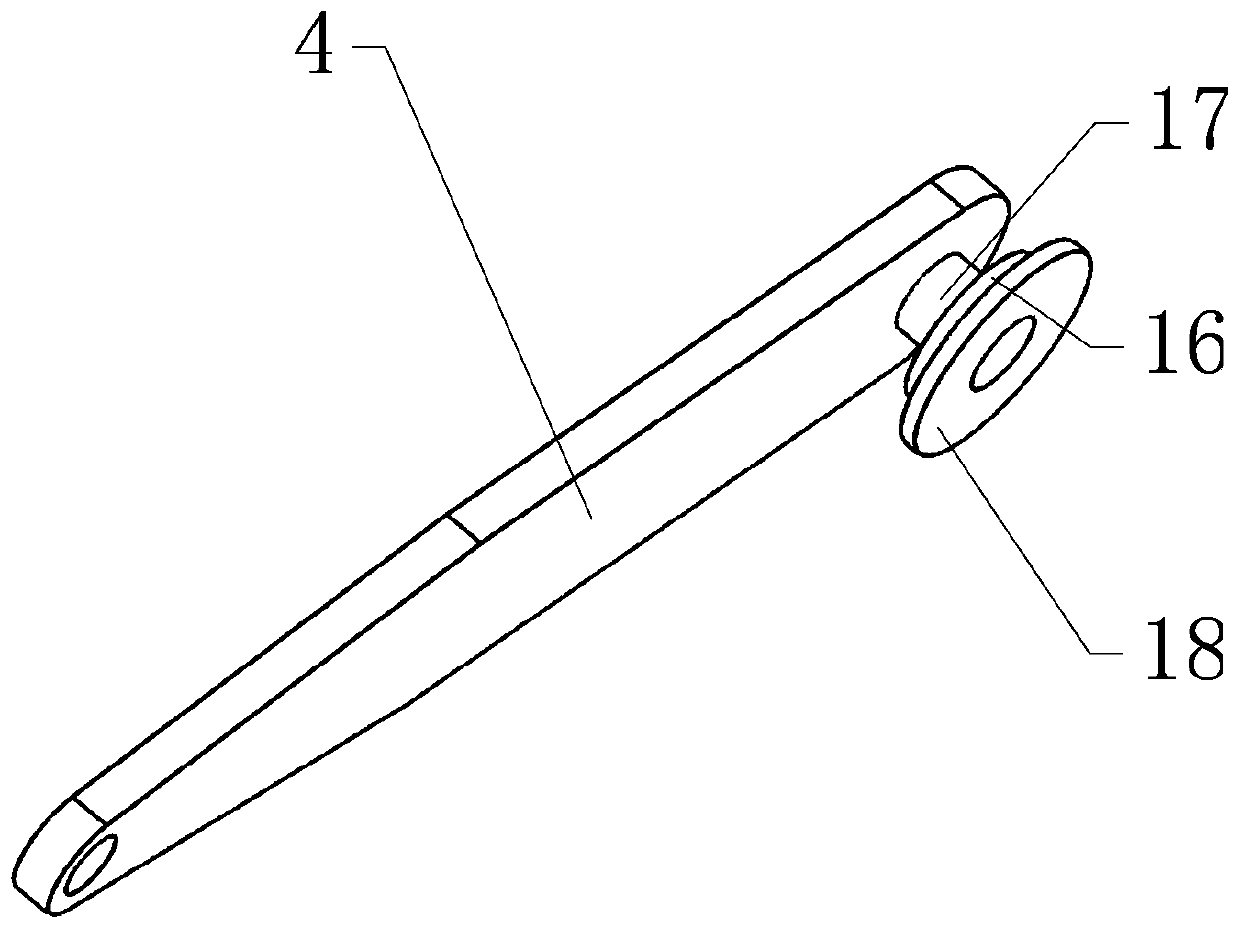

[0035] Such as figure 1 As shown, it includes a motor 1, a reducer 23, a fan-shaped tooth plate 2, a gear 9, a base plate 3, an active arm 4, and a sliding bracket 6 for installing glass. Figure 6 , 7 As shown, the motor 1 is fixedly installed on the base plate 3 through the motor support 24, the reducer 23 is fixedly installed on one side of the base plate 3, and the input shaft of the reducer 23 is connected to the output shaft of the motor 1; the output of the reducer 23 The shaft passes through the base plate 3 and is located on the other side of the base plate 3, the gear 9 is fixedly mounted on the output shaft of the reducer 23; one end of the first hinge shaft 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com