Refueling maintenance device for mechanical equipment

A technology of mechanical equipment and refueling tanks, which is applied in the direction of mechanical equipment, pump devices, quantitative devices, etc. It can solve problems such as affecting maintenance, inconvenient refueling work, and inability to remove dust from mechanical equipment in time, so as to achieve easy maintenance and operation. , the effect of reducing the intensity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

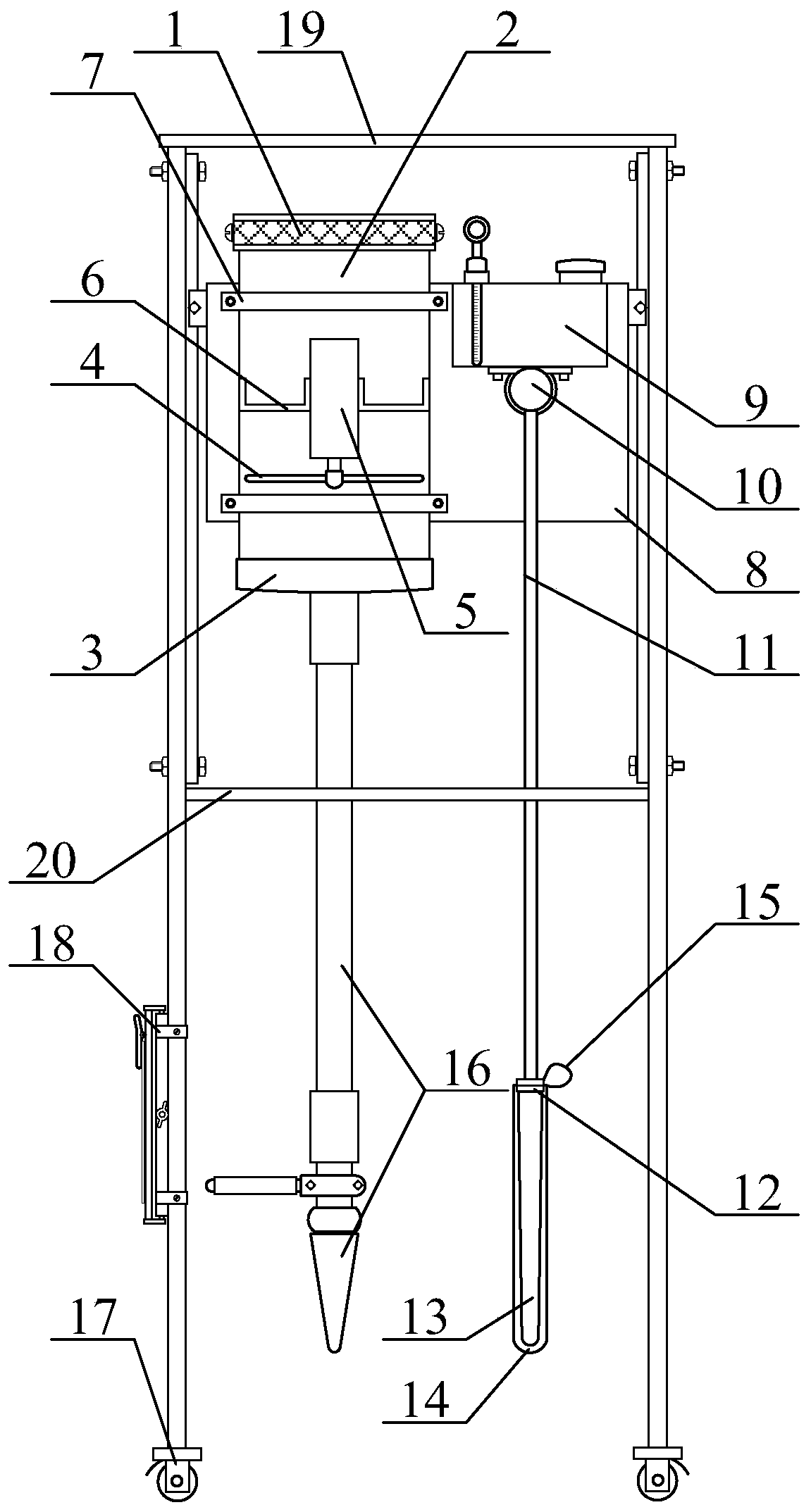

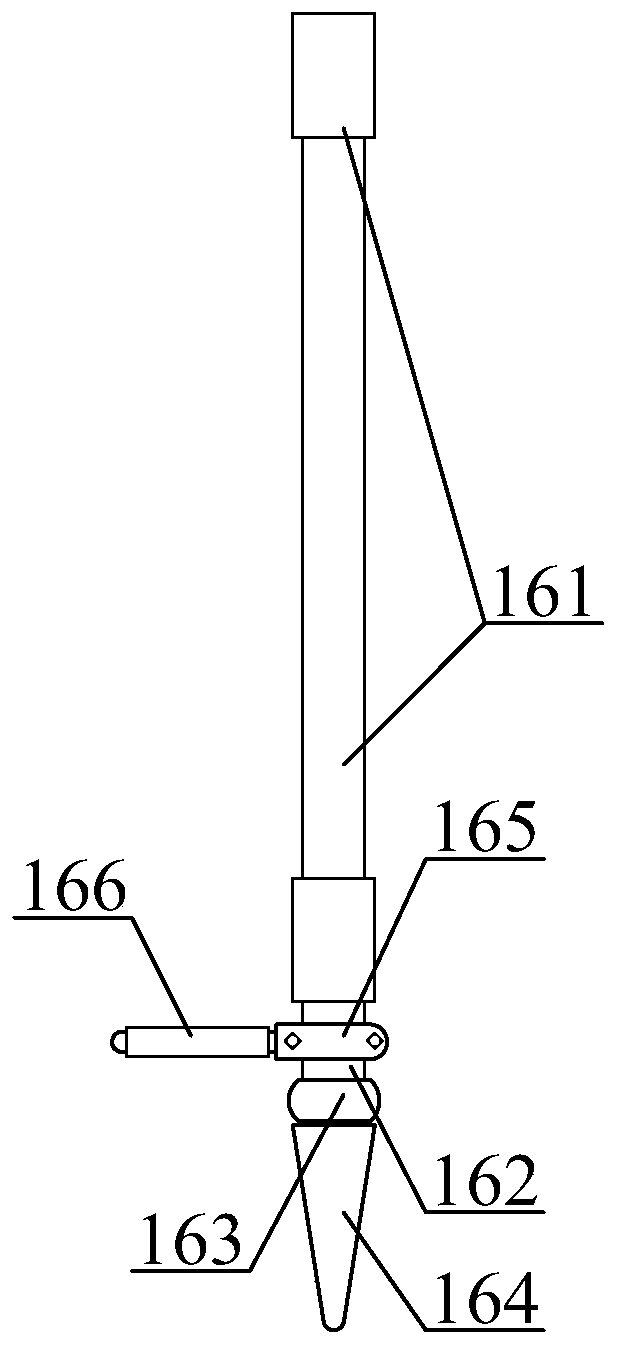

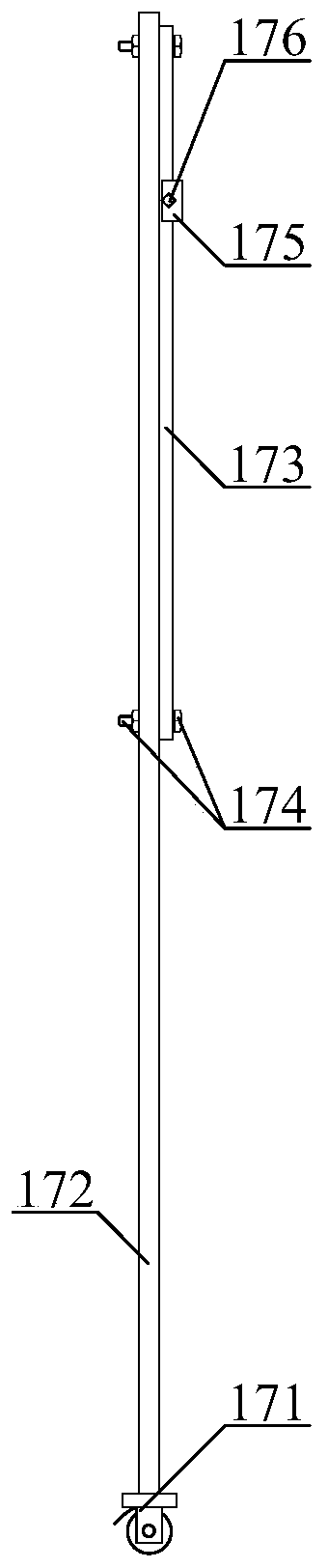

[0054] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 and figure 2 As shown, a refueling and maintenance device for mechanical equipment includes a built-in filter screen air inlet pipe 1, a blower tube 2, a fixed cap 3, fan blades 4, a blower motor 5, a U-shaped fixing frame 6, a hoop piece 7, Fixed plate 8, quantitative detection fuel tank structure 9, fuel suction pump 10, fuel pipe 11, double threaded pipe 12, fuel head 13, dust cap 14, connecting rope 15, portable maintenance dust removal gun structure 16, can slide Adjust the moving wheel structure 17, the rotatable refueling and maintenance recording plate structure 18, the top plate 19 and the middle stable plate 20, and the air inlet pipe of the built-in filter screen air inlet pipe 1 is threadedly connected to the upper entrance of the blower 2; The fixed cap 3 is threadedly connected to the lower end of the blower tube 2; the fan blade 4 is keyed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com