Temperature control driving characteristic testing device for shape memory alloy spring

A technology for memory alloy springs and driving characteristics, which is applied in the direction of elastic testing, measuring devices, and testing of machine/structural components, etc. It can solve the problem of inability to accurately and intuitively reflect the temperature control driving characteristics of SMA springs, and the inability to simultaneously measure the temperature continuity relationship, Restrict the development of SMA springs and other issues to achieve the effect of high degree of automation, high efficiency, and comprehensive data coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The following terms "first", "second" and so on are only described as distinctions.

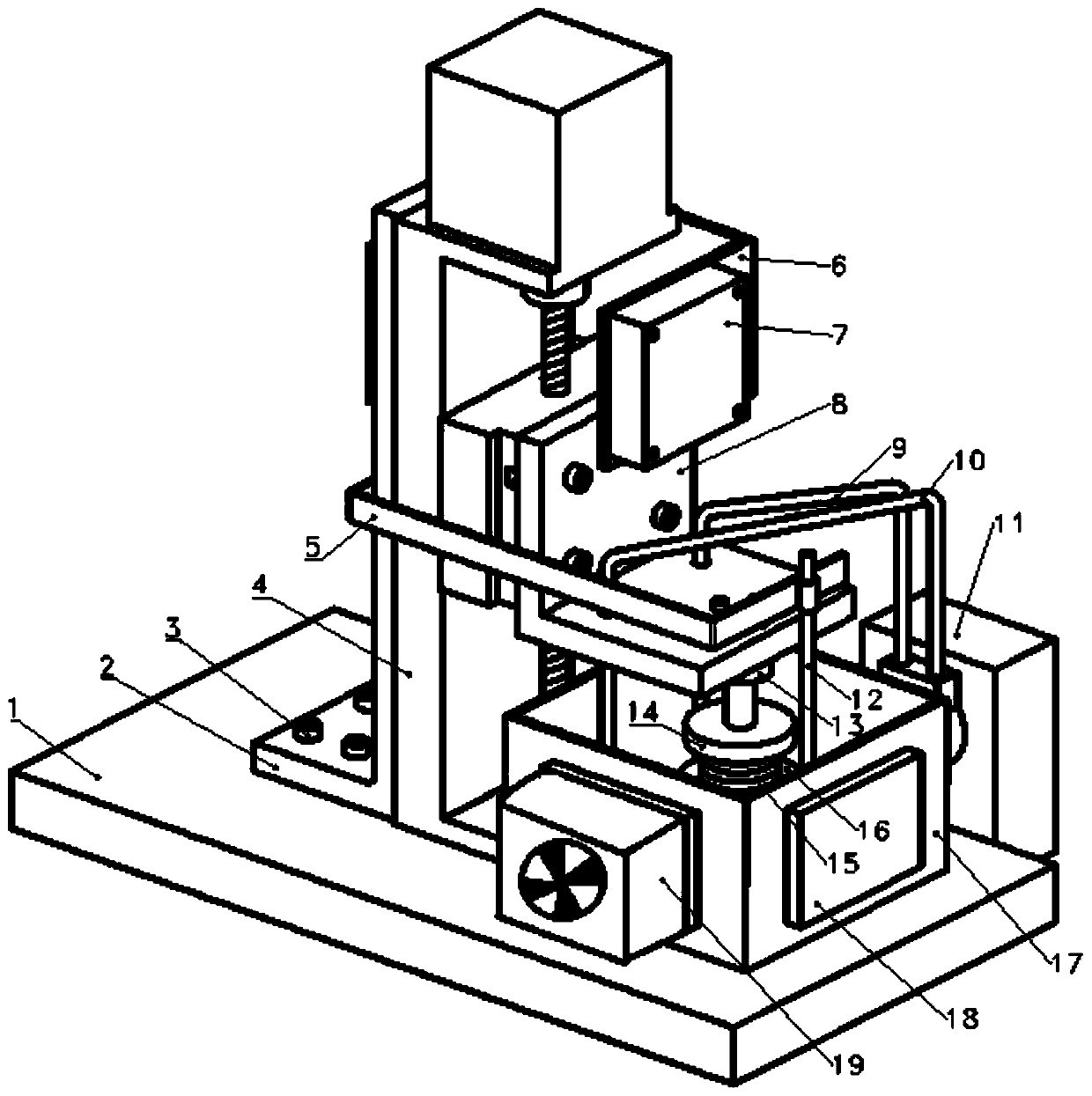

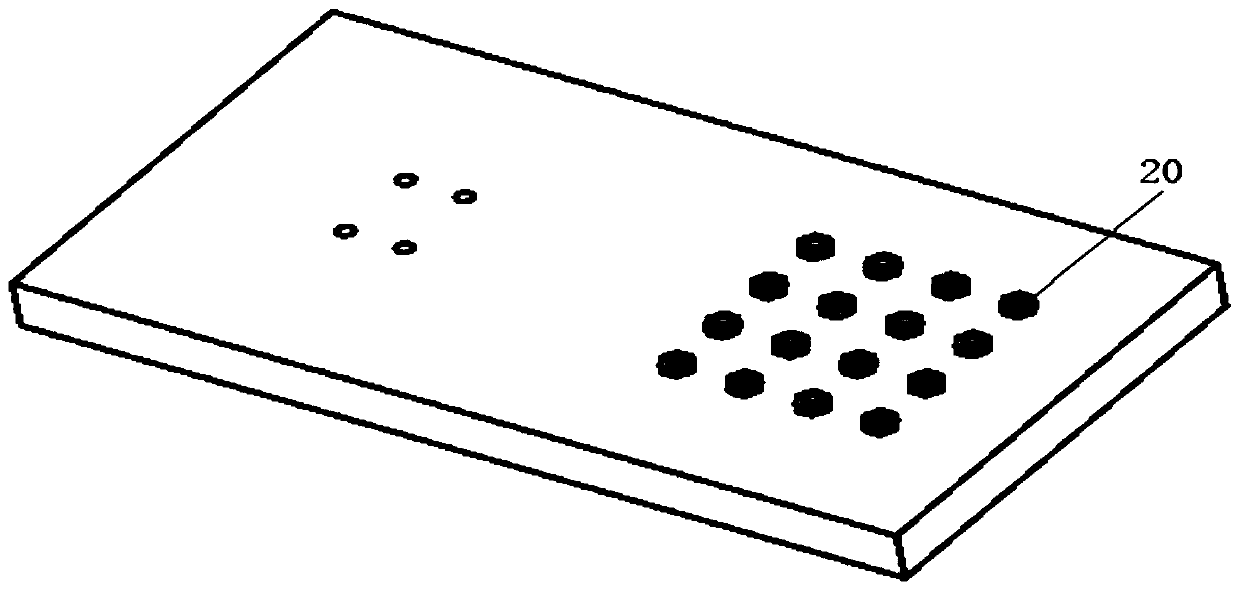

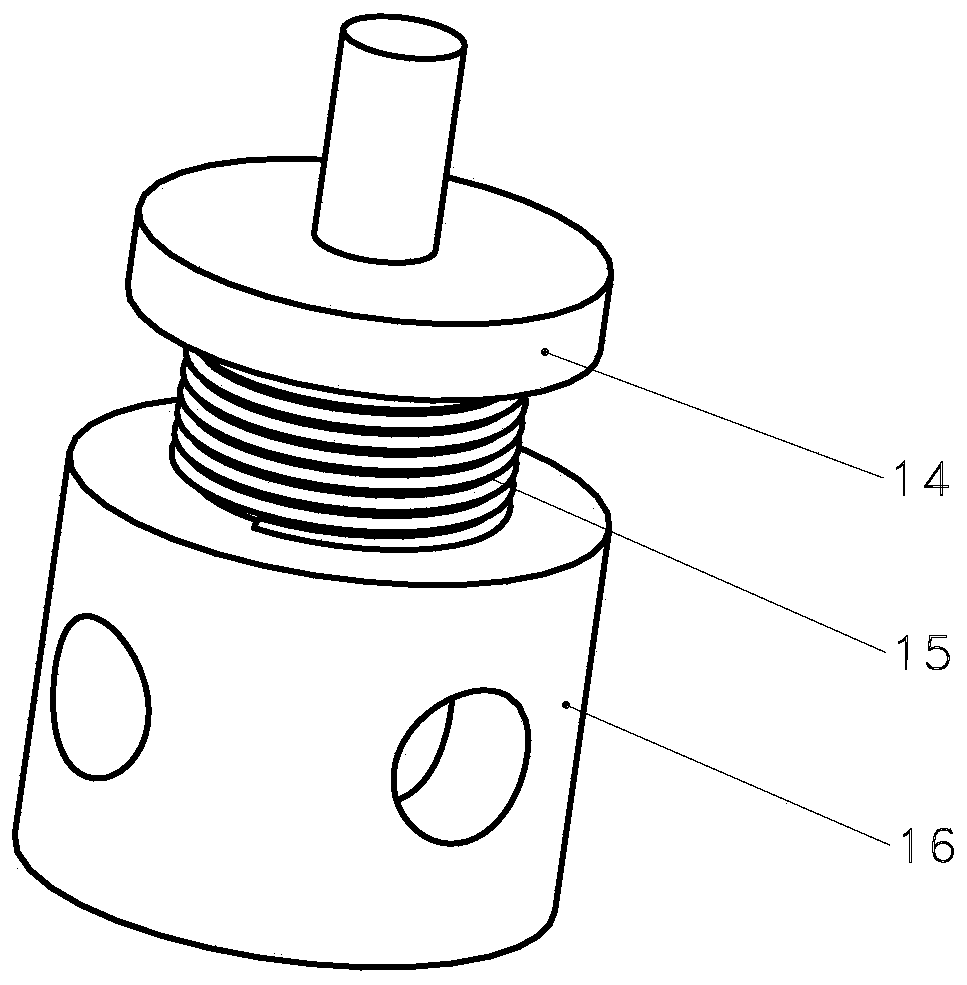

[0023] Such as figure 1 As shown, the shape memory alloy spring temperature control driving characteristic testing device of the present invention includes the following parts: base plate (1), L-shaped bracket (2), hexagon socket head bolt (3), linear slide module (4), temperature Sensor U-shaped connecting frame (5), displacement sensor U-shaped connecting frame (6), laser displacement sensor (7), L-shaped connecting frame (8), water inlet pipe (9), water outlet pipe (10), circulation pump body ( 11), temperature sensor (12), force sensor (13), guide column (14), SMA spring (15), hollow cylindrical spacer (16), water tank (17), ceramic heater (18), semiconductor refrigeration sheet (19), nut (20). There are four through holes under the L-shaped bracket (2), which are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com