Hydrogen cell endurance test method

A technology of fuel cells and testing methods, applied in the fields of fuel cells, circuits, measuring electricity, etc., can solve the problems of few collected samples, inaccurate experimental data, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

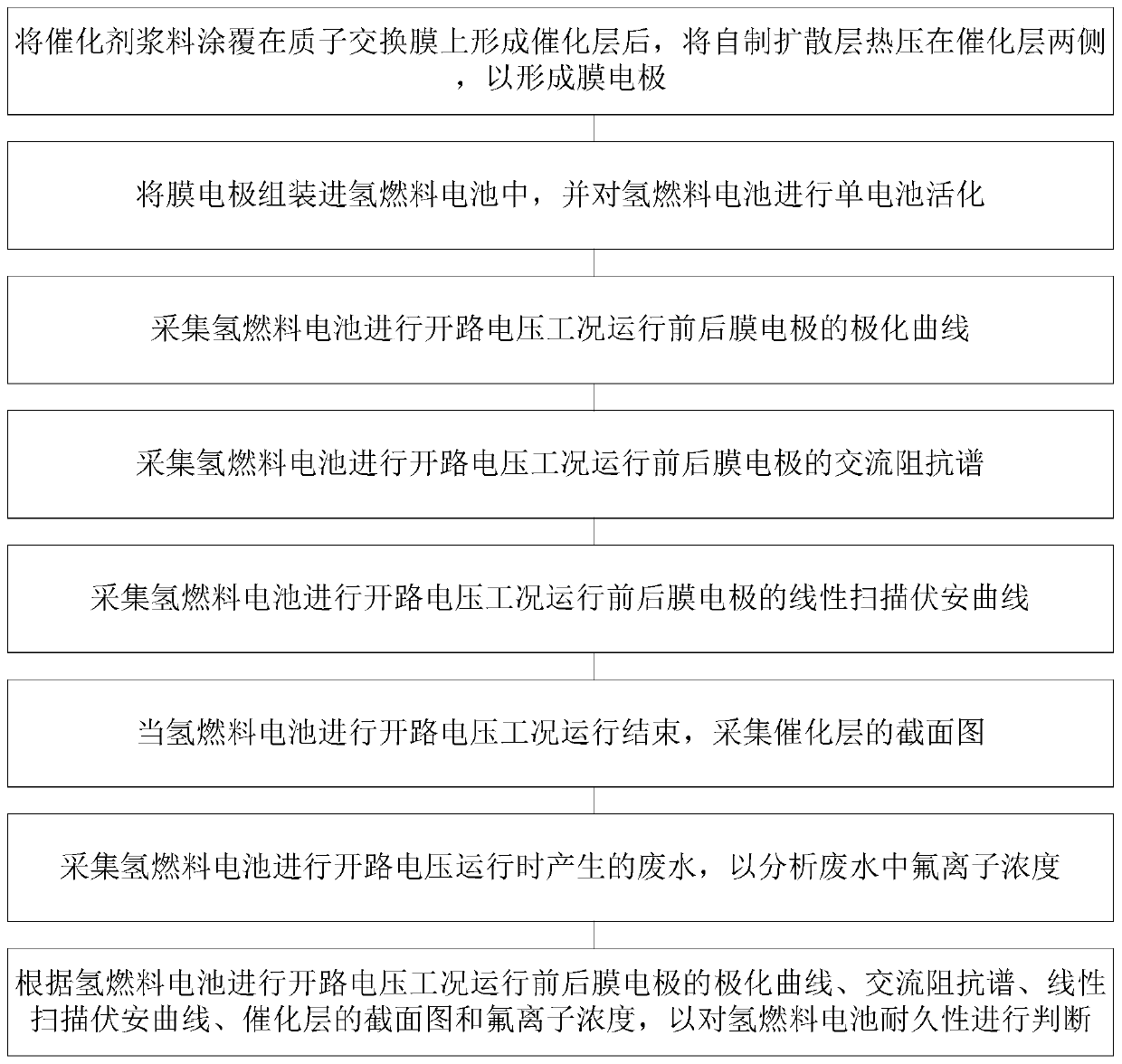

[0047] figure 1 It is a functional block diagram of the hydrogen fuel cell endurance test method of the present invention.

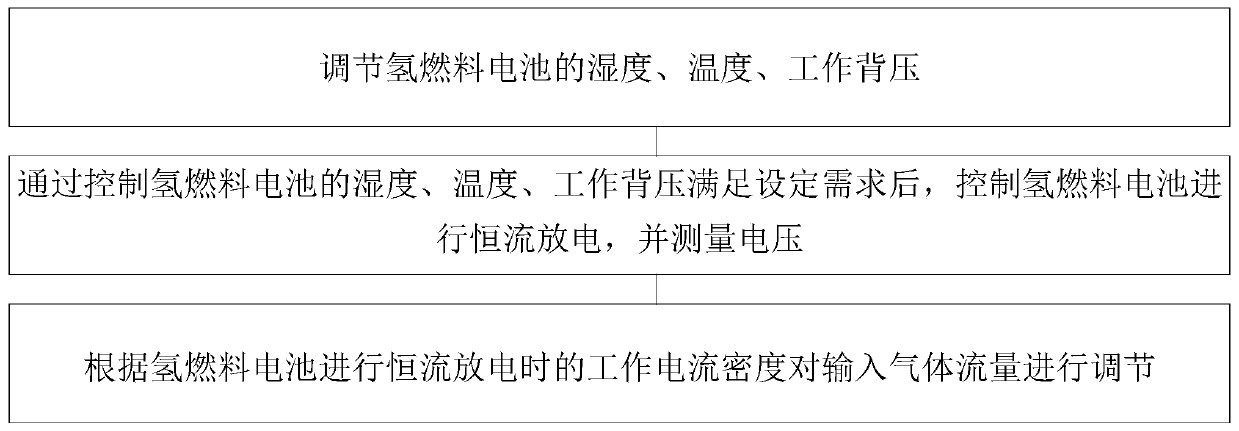

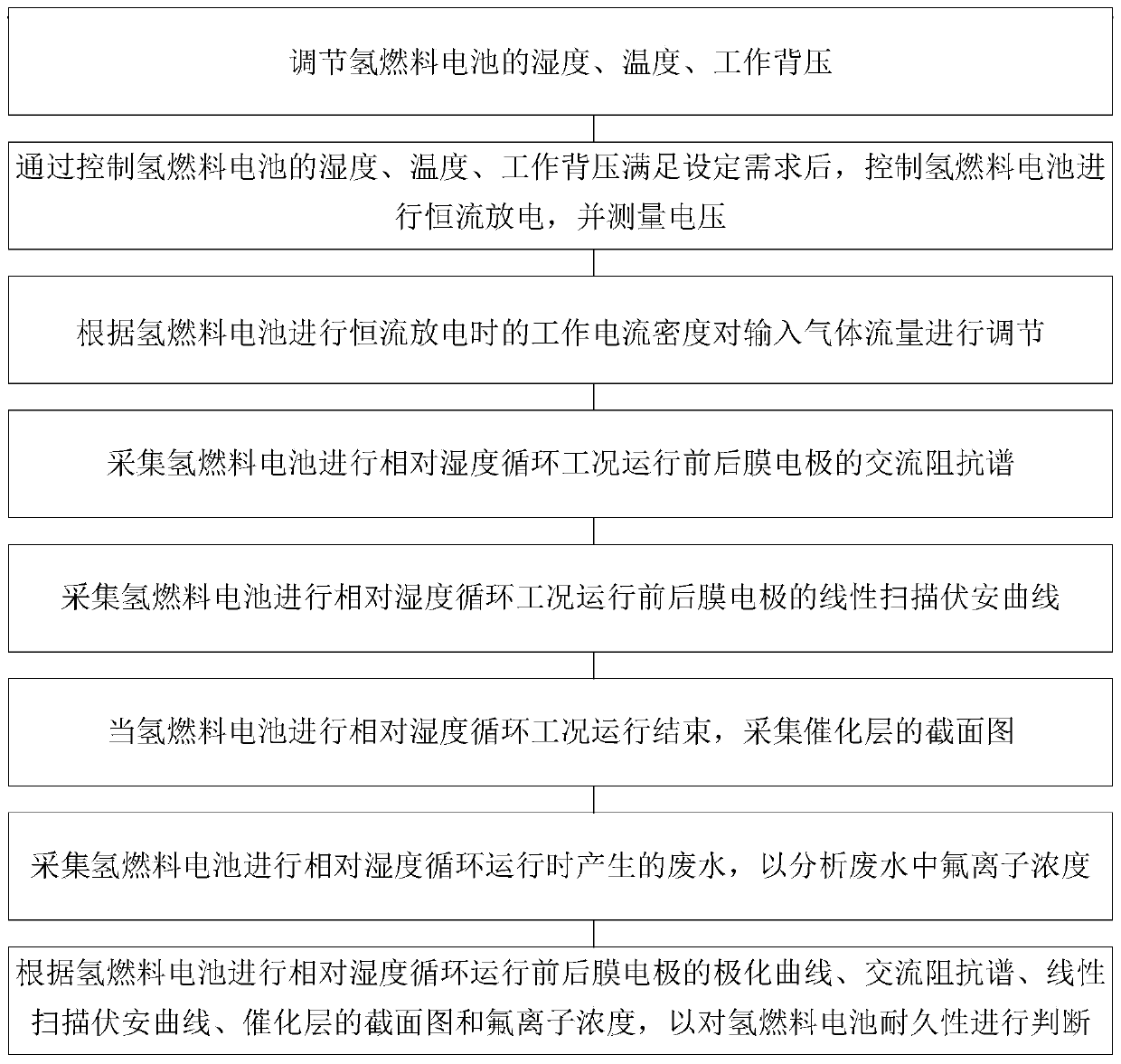

[0048] In this example, if figure 1As shown, this embodiment provides a hydrogen fuel cell durability test method, which includes: after coating the catalyst slurry on the proton exchange membrane to form a catalytic layer, hot pressing the self-made diffusion layer on both sides of the catalytic layer to form Membrane electrode; assemble the membrane electrode into the hydrogen fuel cell, and activate the single cell of the hydrogen fuel cell; control the battery temperature range of the hydrogen fuel cell to 50-80°C, and the humidification relative humidity range to 50-70%, without working back Pressure, adjust the input gas flow to control the utilization rate of hydrogen and air, that is, the range of hydrogen utilization rate is controlled at 60%-70%, and the range of air utilization rate is controlled at 35%-45%; hydrogen fuel cells are collected ...

Embodiment 2

[0064] In this embodiment, this embodiment provides a hydrogen fuel cell durability accelerated test system, which includes: a hot press, a fuel cell test module, an impedance meter, an electrochemical workstation, a scanning electron microscope, and an ion chromatograph; wherein After the catalyst slurry is coated on the proton exchange membrane to form a catalytic layer, the hot press is suitable for hot pressing the self-made diffusion layer on both sides of the catalytic layer to form a membrane electrode; the membrane electrode is assembled into a hydrogen fuel cell, And perform single-cell activation on the hydrogen fuel cell; the fuel cell test module is suitable for collecting the polarization curve of the membrane electrode before and after the open circuit voltage operation of the hydrogen fuel cell; the impedance meter is suitable for collecting the hydrogen fuel cell for open circuit voltage work The AC impedance spectrum of the membrane electrode before and after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com