Dielectric capacitor

A technology of dielectric capacitance and capacitance layer, which is applied in the direction of capacitors, circuits, electrical components, etc., can solve the problems of restricting the increase of the capacitance value per unit area and the inability to increase the capacitance value of the capacitance per unit area, and achieve the effect of increasing the capacitance value per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

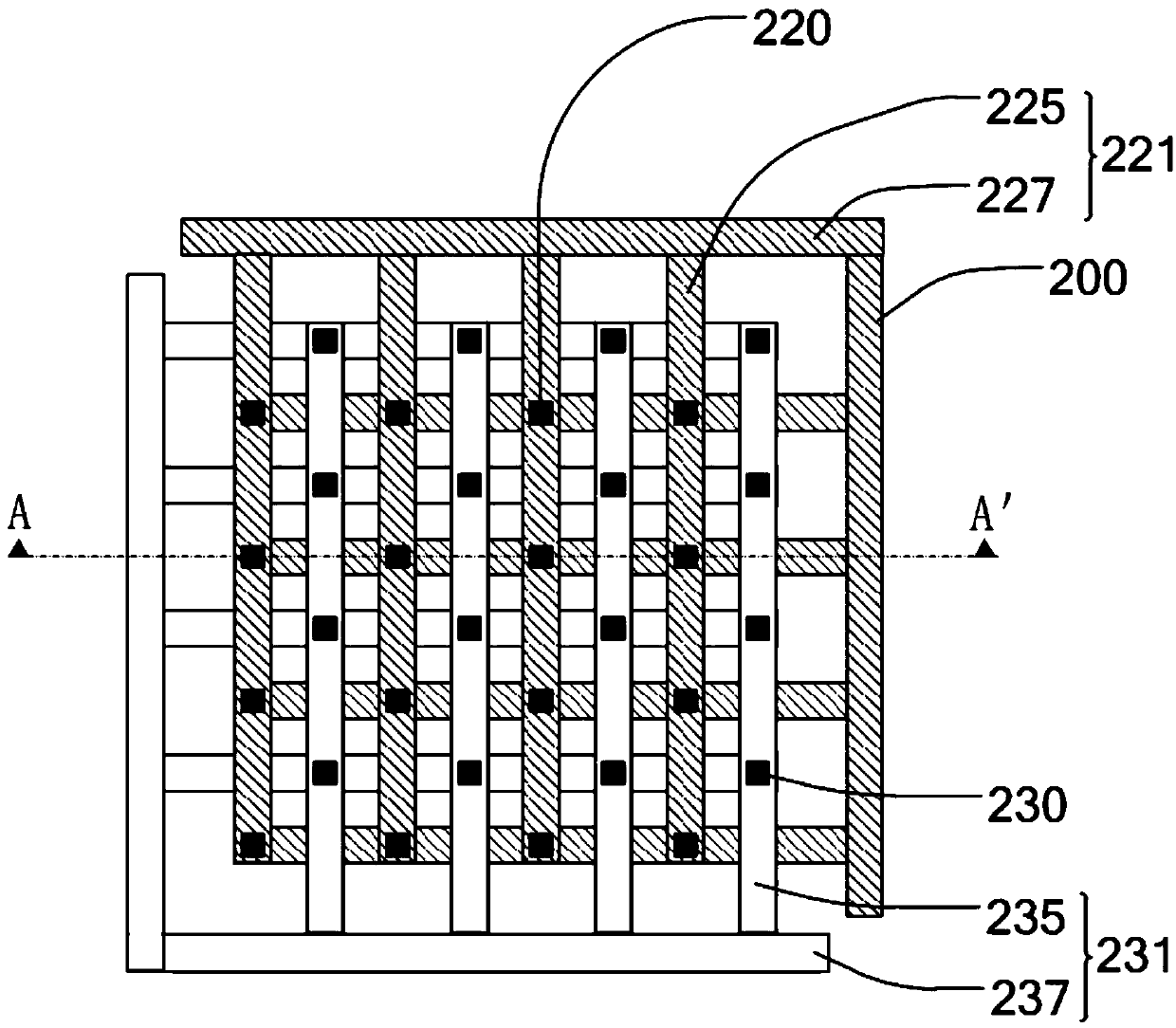

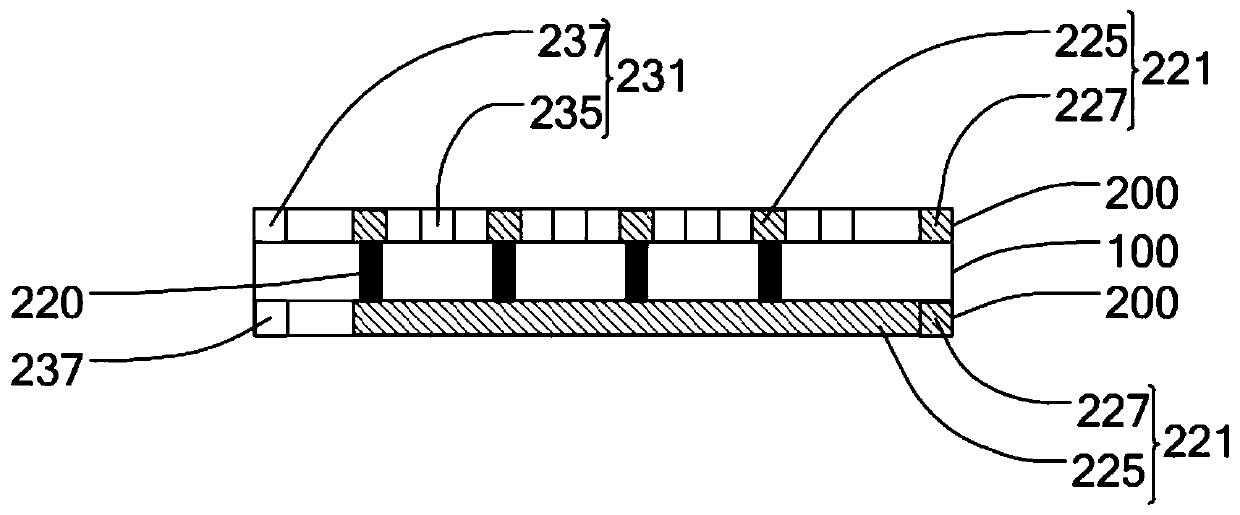

[0032] figure 2 is a top view of the dielectric capacitor of the first embodiment, image 3 for along figure 2 The side sectional view of the line A-A' in the middle.

[0033] In this example, see figure 2 As shown, a dielectric capacitor includes at least two capacitor layers 200, each capacitor layer 200 has a positive electrode 221 and a negative electrode 231, and a dielectric material is filled between the positive electrode 221 and the negative electrode 231 (the dielectric material is in the figure 1 not shown). Positive electrode 221 is made up of a first part 227 and several intervals in parallel and is respectively joined to the second part 225 on one side of this first part 227, and negative electrode 231 is made up of a first part 237 and several intervals in parallel and is joined respectively. On one side of the first part 237 the second part 235 is formed. And in each capacitive layer 200, the second part 225 of the positive electrode 221 and the second ...

no. 2 example

[0039] In this example, see Figure 5 As shown, the capacitor layer is divided into a plurality of odd-number capacitor layers 300 and a number of even-number capacitor layers 400 that are alternately stacked. The alternate stacking method is specifically that an even-number capacitor layer 400 is arranged between every two odd-number capacitor layers 300, and a dielectric layer 500 is arranged between adjacent odd-number capacitor layers 300 and even-number capacitor layers 400. . Also, in order to clearly show the structure and arrangement of comb electrodes and vias, Figure 4 , Figure 5 , Image 6 with Figure 7 The dielectric materials filled in the odd-number capacitor layer 300 , the even-number capacitor layer 400 and the dielectric layer 500 are not shown in the figures.

[0040] see Image 6 The top view of the odd-numbered capacitor layer of the dielectric capacitor, the comb-tooth portion 325 of the positive electrode 321 in the odd-numbered capacitor layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com