Closed noise reduction ultrasonic cleaning machine

An ultrasonic and cleaning machine technology, applied in the direction of sound-producing equipment, mechanical equipment, cleaning methods and utensils, etc., can solve the problems that the cleaning machine does not have the sound insulation function, the cleaning machine does not have the shock absorption effect, the vibration effect of the surrounding equipment, etc., and achieves good performance. Sound insulation effect, the effect of avoiding noise escaping, reducing the possibility of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

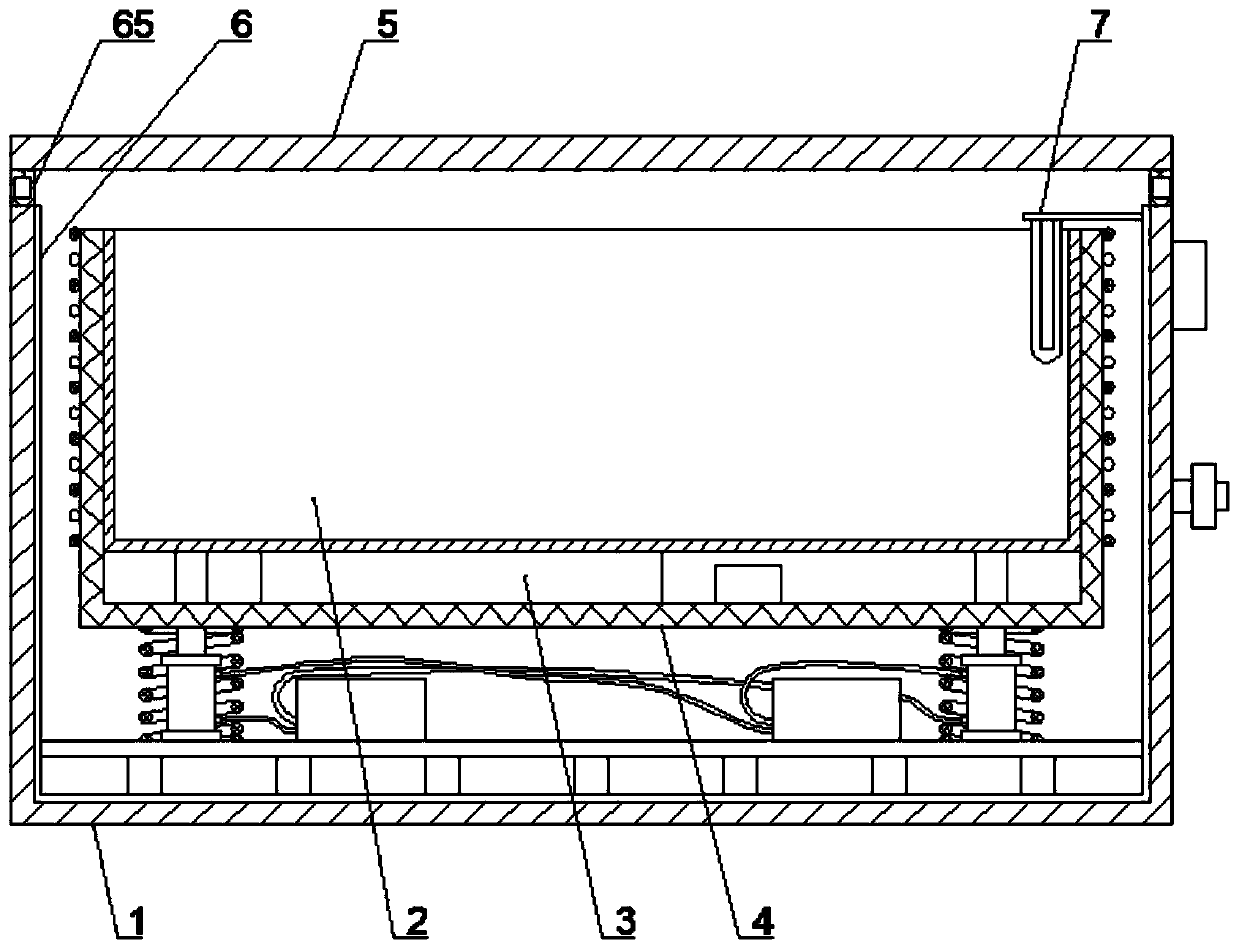

[0037] like figure 1 A closed noise-reducing ultrasonic cleaning machine shown includes: a housing 1, a silo 2, an ultrasonic generator 3, an energy-absorbing mechanism 4, and a machine hatch 5. The housing 1 is provided with a silo 2, An ultrasonic generator 3 is arranged outside the silo 2, an energy-absorbing mechanism 4 is arranged outside the ultrasonic generator 3, and the energy-absorbing mechanism 4 is fixed on the casing 1, and an organic platform cabin is arranged on the top of the casing 1 door 5;

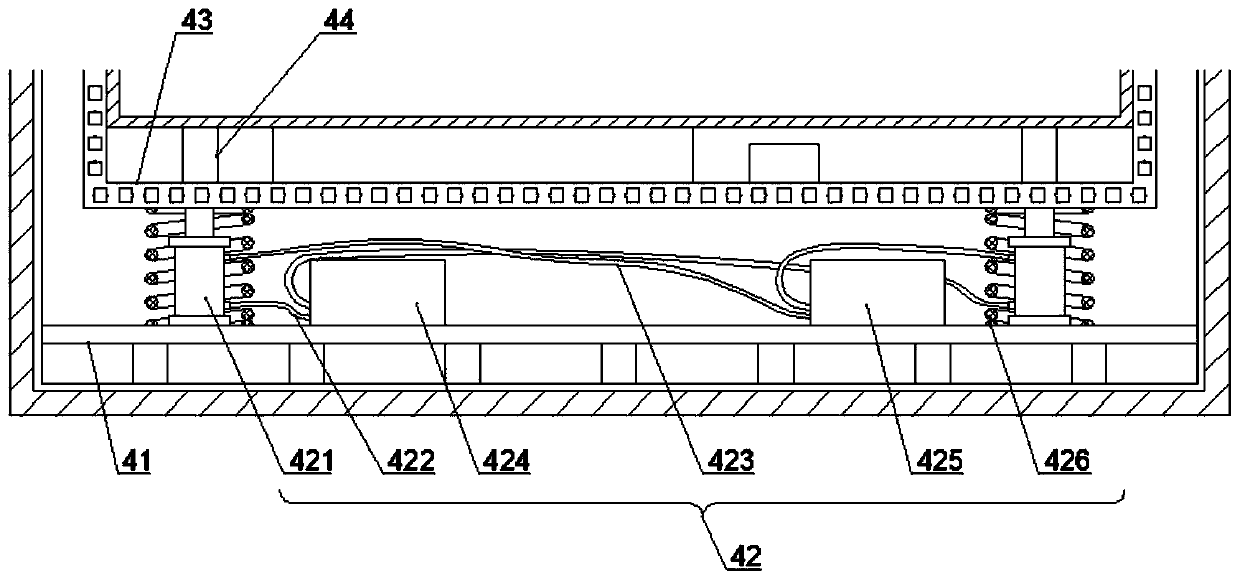

[0038]The energy-absorbing mechanism 4 includes a fixed bracket 41, a buffer layer 42, an energy-absorbing layer 43 and a fixed connector 44. The fixed bracket 41 is arranged inside the housing 1, and the fixed bracket 41 is provided with a buffer layer 42. An energy-absorbing layer 43 is arranged inside the buffer layer 42 , and a fixed connector 44 is arranged inside the energy-absorbing layer 43 , and one end of the fixed connector 44 is connected to the silo 2 .

...

Embodiment 2

[0046] like figure 2 A closed noise-reducing ultrasonic cleaning machine shown includes: a housing 1, a silo 2, an ultrasonic generator 3, an energy-absorbing mechanism 4, and a machine hatch 5. The housing 1 is provided with a silo 2, An ultrasonic generator 3 is arranged outside the silo 2, an energy-absorbing mechanism 4 is arranged outside the ultrasonic generator 3, and the energy-absorbing mechanism 4 is fixed on the casing 1, and an organic platform cabin is arranged on the top of the casing 1 door 5;

[0047] The energy-absorbing mechanism 4 includes a fixed bracket 41, a buffer layer 42, an energy-absorbing layer 43 and a fixed connector 44. The fixed bracket 41 is arranged inside the housing 1, and the fixed bracket 41 is provided with a buffer layer 42. An energy-absorbing layer 43 is arranged inside the buffer layer 42 , and a fixed connector 44 is arranged inside the energy-absorbing layer 43 , and one end of the fixed connector 44 is connected to the silo 2 . ...

Embodiment 3

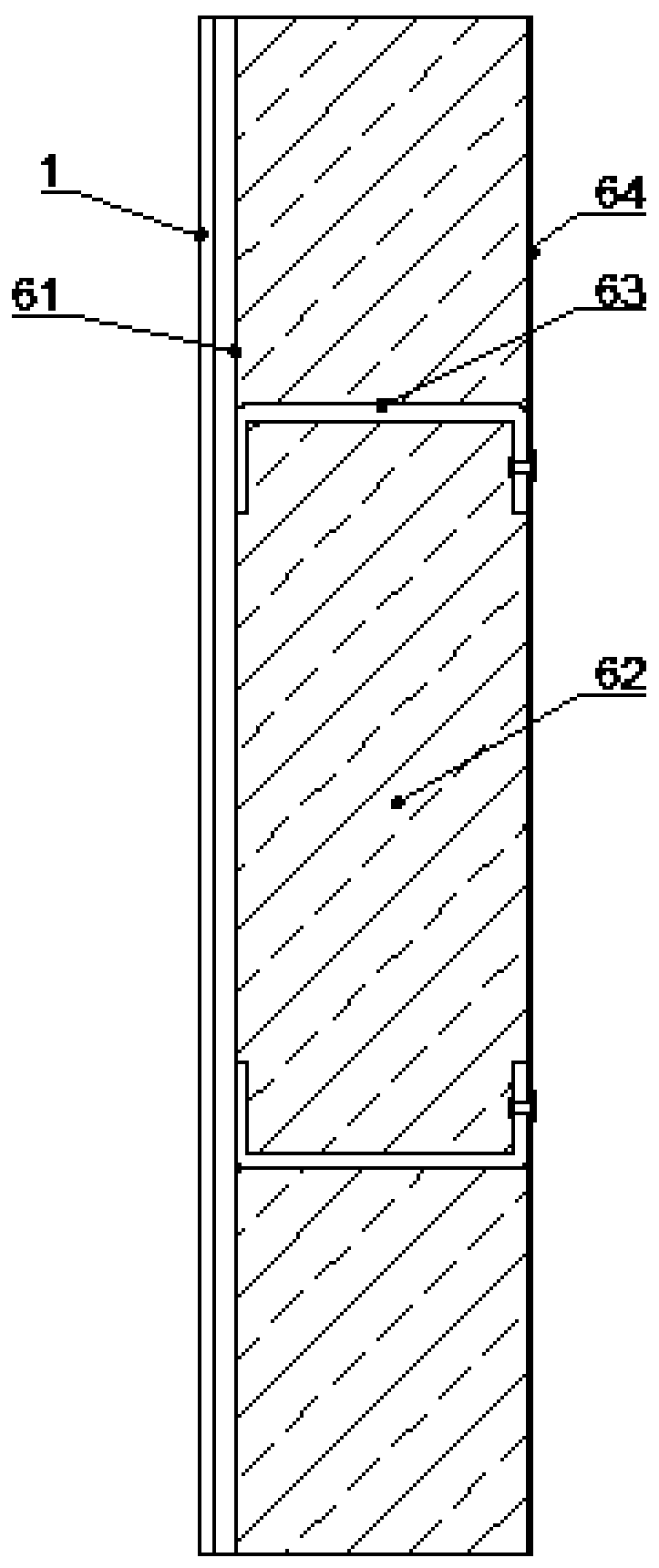

[0050] like figure 1 and 3 A closed noise-reducing ultrasonic cleaning machine shown includes: a housing 1, a silo 2, an ultrasonic generator 3, an energy-absorbing mechanism 4, and a machine hatch 5. The housing 1 is provided with a silo 2, An ultrasonic generator 3 is arranged outside the silo 2, an energy-absorbing mechanism 4 is arranged outside the ultrasonic generator 3, and the energy-absorbing mechanism 4 is fixed on the casing 1, and an organic platform cabin is arranged on the top of the casing 1 door 5;

[0051] The energy-absorbing mechanism 4 includes a fixed bracket 41, a buffer layer 42, an energy-absorbing layer 43 and a fixed connector 44. The fixed bracket 41 is arranged inside the housing 1, and the fixed bracket 41 is provided with a buffer layer 42. An energy-absorbing layer 43 is arranged inside the buffer layer 42 , and a fixed connector 44 is arranged inside the energy-absorbing layer 43 , and one end of the fixed connector 44 is connected to the silo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com