Premixed concrete cooling system, concrete mixing station and pump truck

A technology for ready-mixed concrete and cooling system, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of uneven stress distribution, internal crack strength, rapid loss of slump speed, etc., to improve the cooling effect, The effect of increasing the contact area and reducing the interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

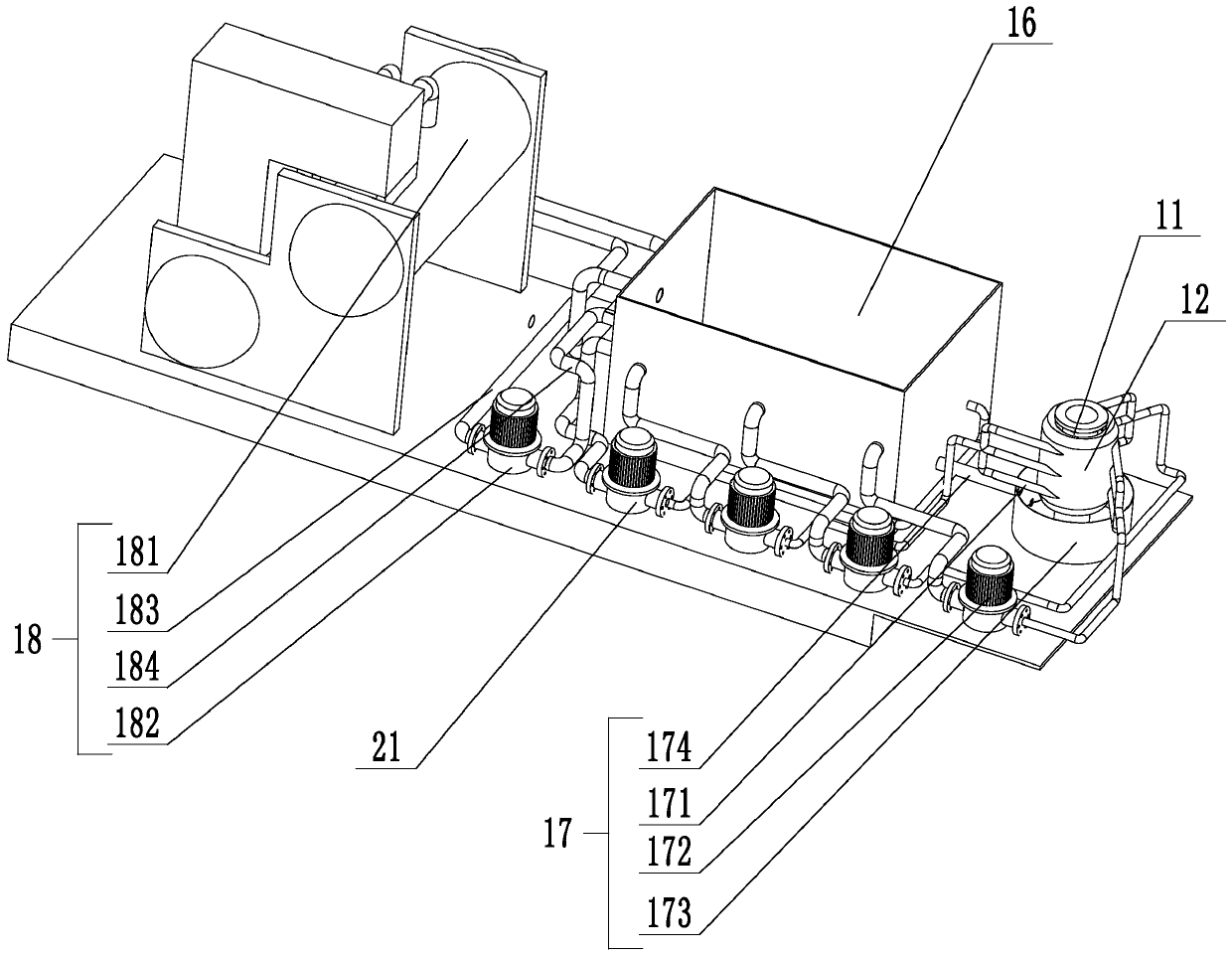

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

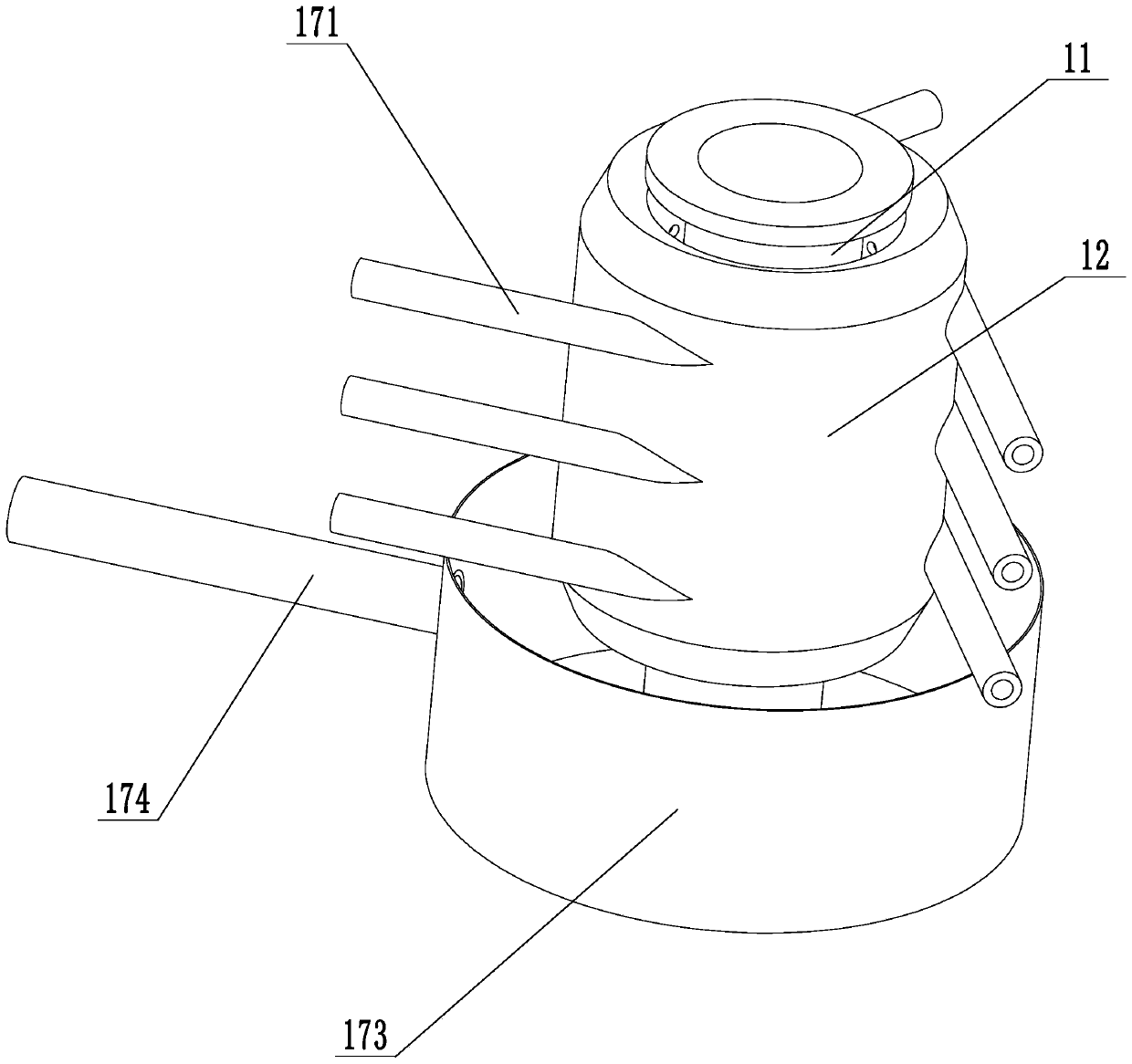

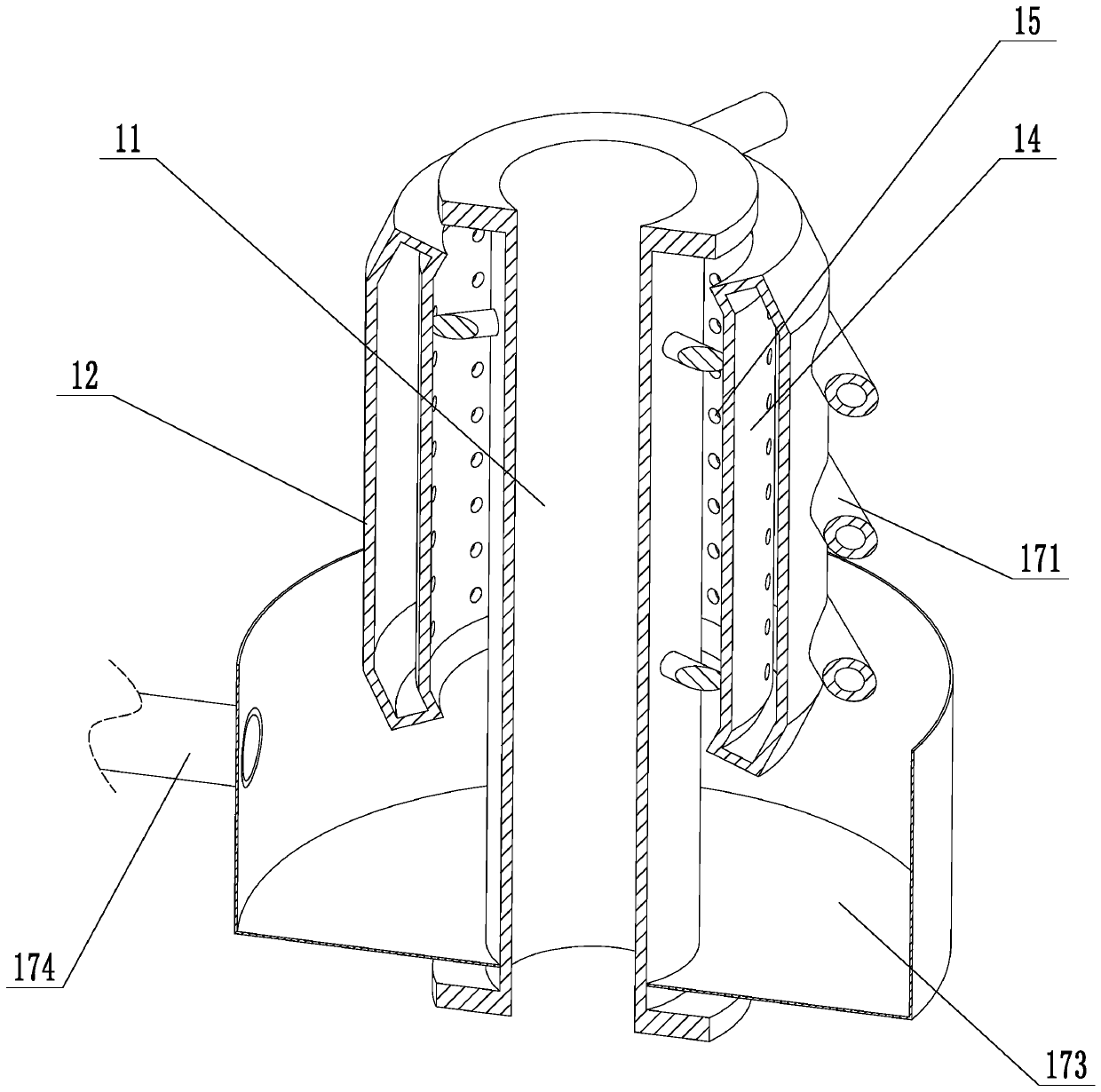

[0053] refer to figure 1 , is a ready-mixed concrete cooling system disclosed in the embodiment of the present invention, mainly composed of a material pipe 11, a cold water jacket 12, a cold water pool 16, a cold water circulation part 17 and a refrigeration part 18, etc. The material pipe 11 is a channel, and its function is The finished ready-mixed concrete is transported. The ready-mixed concrete flows in from one end of the feed pipe 11 and flows out from the other end after heat exchange.

[0054] refer to figure 2 and image 3 , the cooling water jacket 12 is a ring-shaped sleeve with a section fixed on the outer wall of the material tube 11 through a connecting rod, and there is a gap between the inner wall and the outer wall of the material tube 11. The role of the gap provides a space for the cooling water, which can This enables it to be evenly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com