Sound absorption gypsum board positional punching machining machine and machining method

A gypsum board and hole processing technology, which is used in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as environmental pollution, inability to discharge materials, and inability to clean gypsum dust, so as to avoid environmental pollution and facilitate subsequent processing. , the punching effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

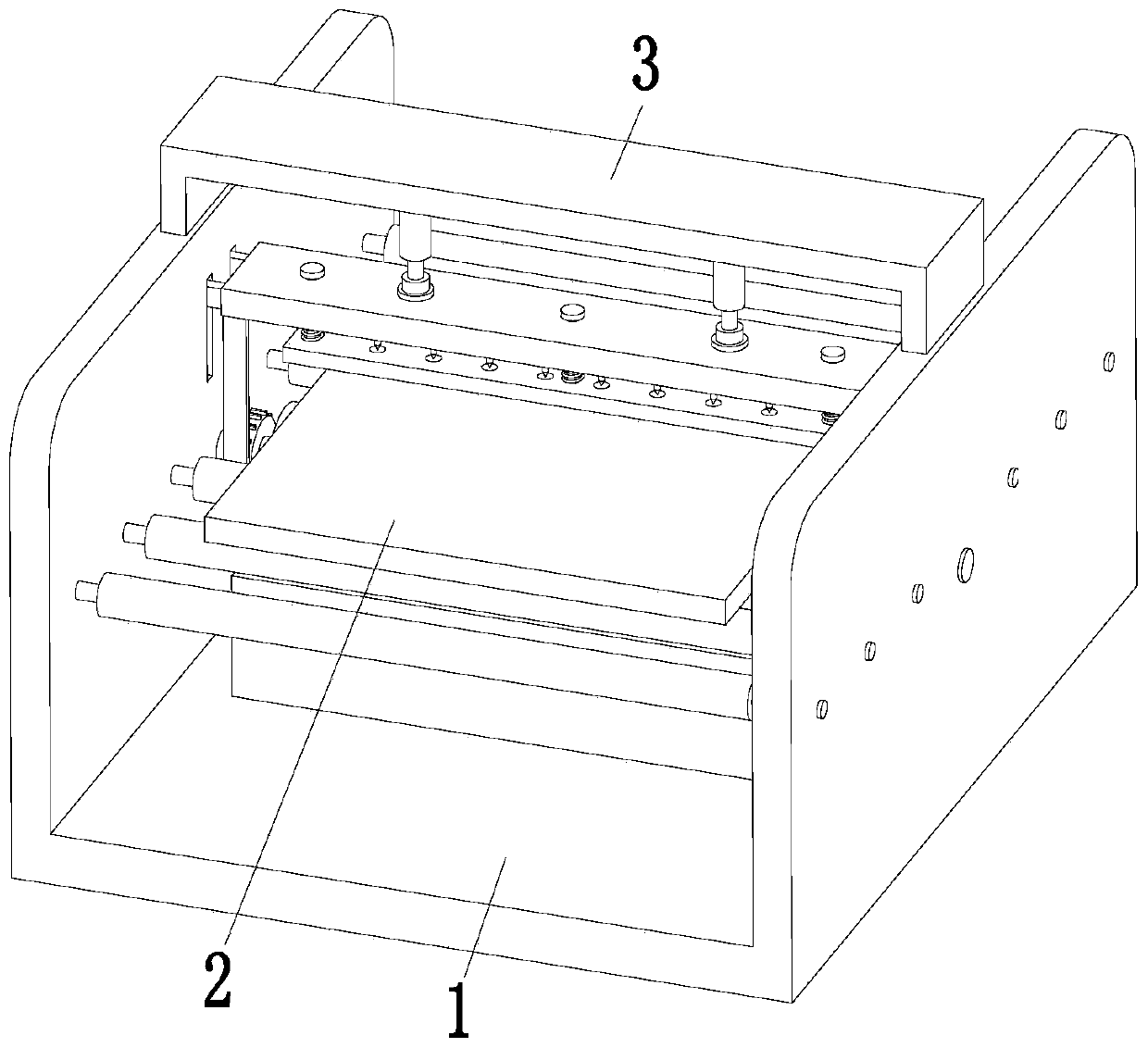

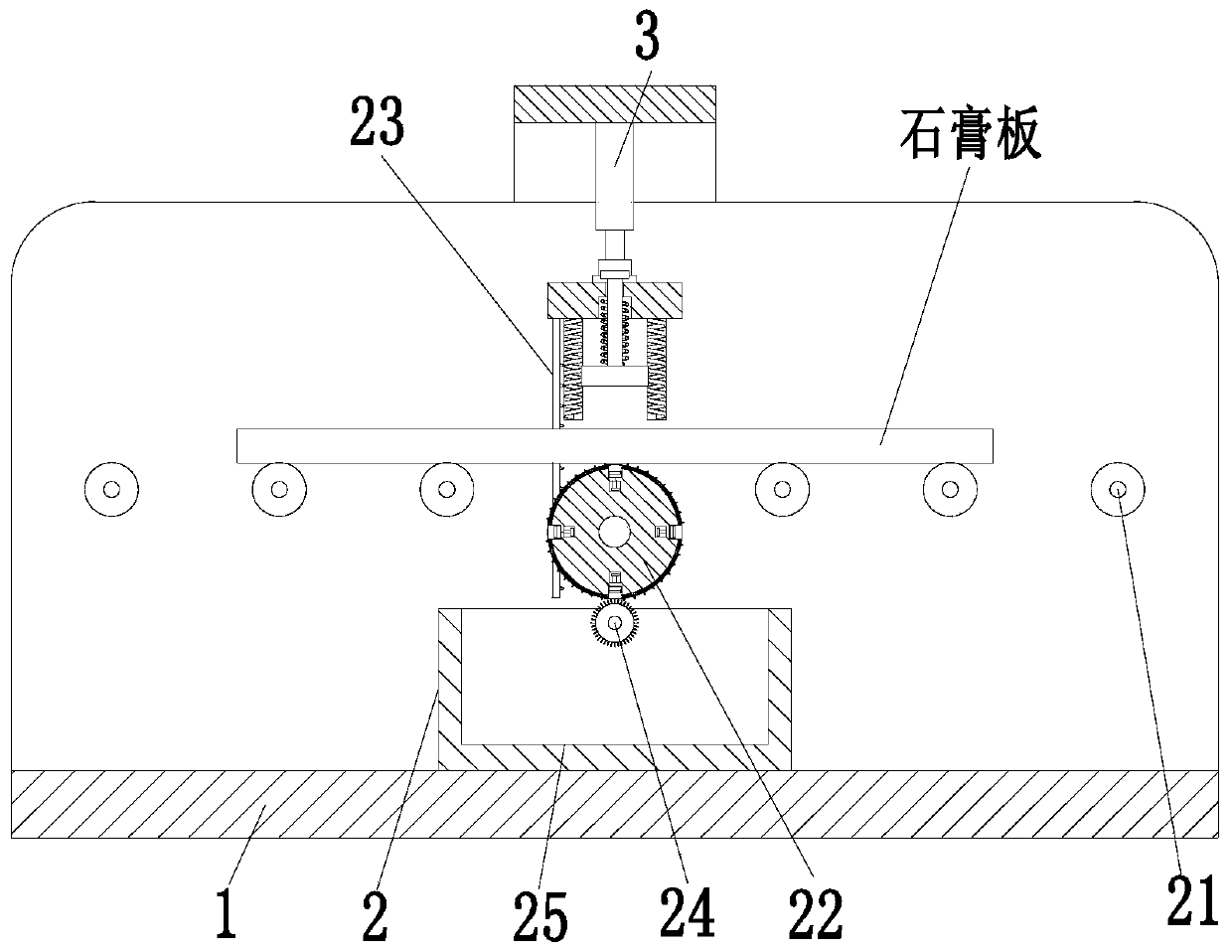

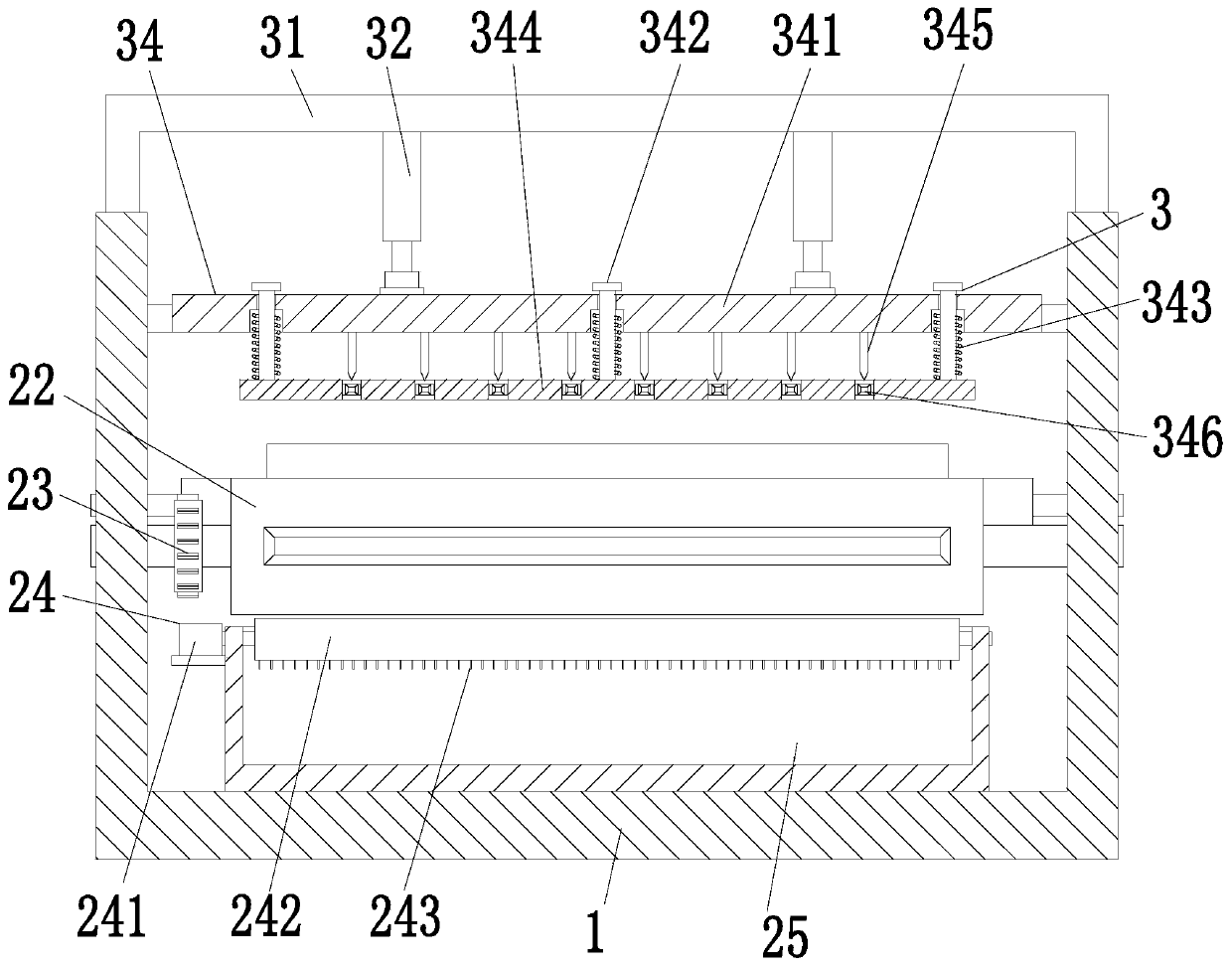

[0032] like Figure 1 to Figure 5 As shown, a sound-absorbing gypsum board positioning punching processing machine includes a support frame 1, a collection device 2 and a punching device 3. The support frame 1 is in a U-shaped structure, and the lower end of the support frame 1 is equipped with a collection device 2. A punching device 3 is arranged above the collecting device 2 , and the punching device 3 is installed on the support frame 1 .

[0033] The collection device 2 includes a support roller 21, a rotating roller 22, an intermittent mechanism 23, a cleaning mechanism 24 and a collection box 25. The inside of the support frame 1 is equipped with a support roller 21 through a pin shaft, and the inside of the support frame 1 passes through Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com