Device for improving yarn flexibility

A soft and high-performance technology, which is applied in the field of devices for improving yarn smoothness, can solve the problems of low efficiency, inability to guarantee yarn smoothness, yarn surface smoothness and bright color, etc., to improve processing efficiency, bright color, The effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

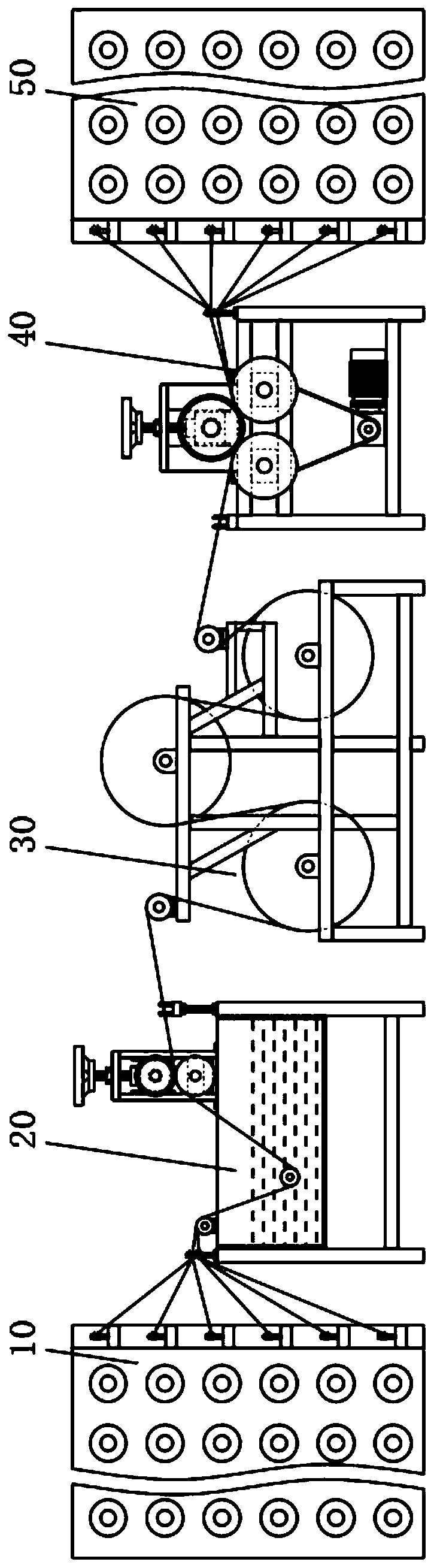

[0051] Embodiment one, with reference to figure 1, a device for improving the suppleness of yarn, comprising a pay-off unit 10, a soaking unit 20, a warming unit 30, a traction transition unit 40, a take-up unit 50, a pay-off unit 10, a soaking unit 20, a warming unit 30, The traction transition unit 40 and the take-up unit 50 are arranged sequentially from left to right, the top surface of the soaking unit 20 is equipped with a wire assembly 80, an adjustment assembly 60 and a comb line assembly 70 from left to right, and the top surface of the traction transition unit 40 is from left to right Comb wire assembly 70, adjustment assembly 60 and lead wire assembly 80 are installed, and the pay-off unit 10, soaking unit 20, comforting unit 30, traction transition unit 40, and take-up unit 50 are arranged between two adjacent units from left to right. The distance shall not be less than 1.5 meters, and the yarns to be processed in the pay-off unit 10 are wound as shown in the figu...

Embodiment 2

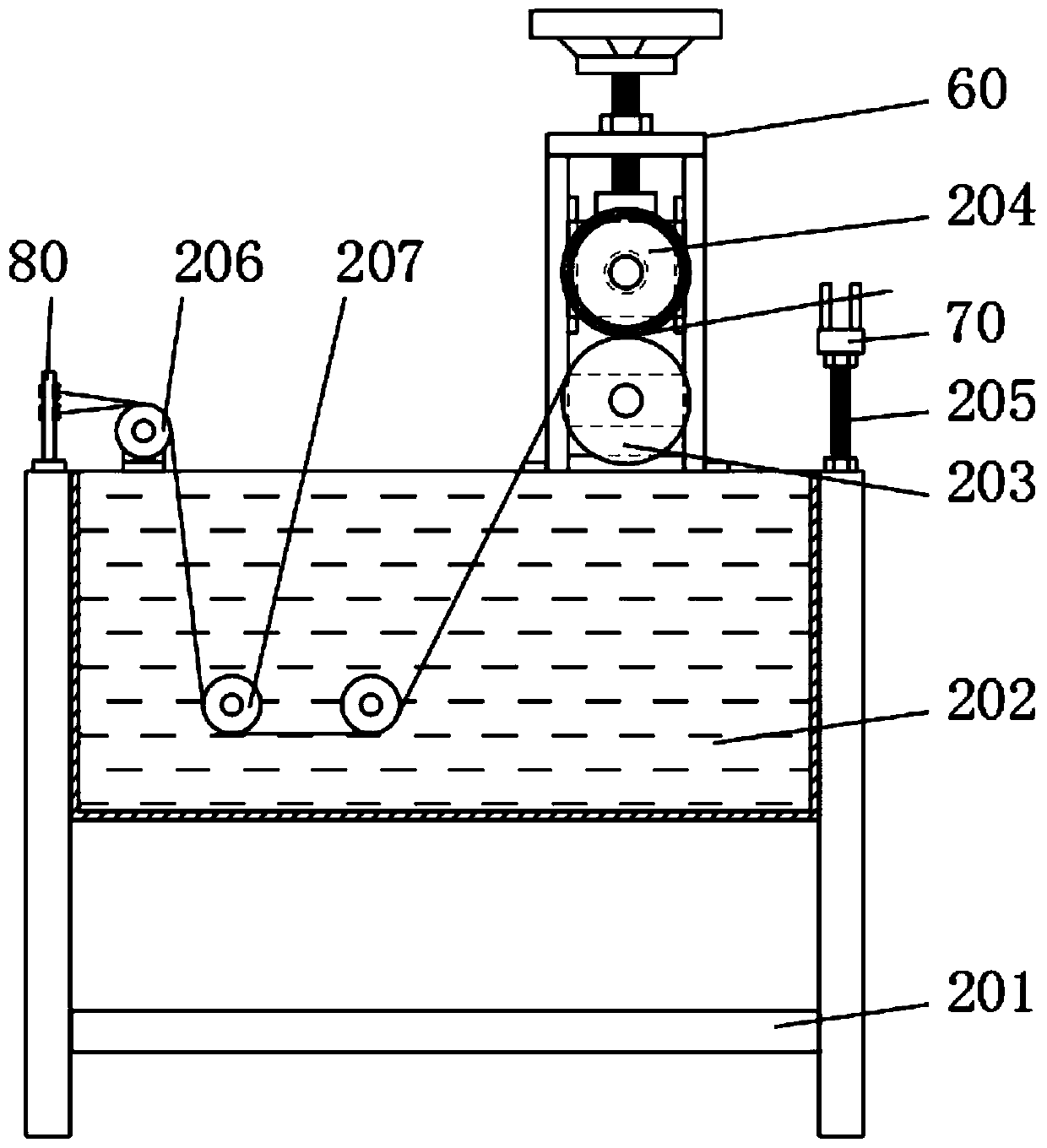

[0052] Embodiment two, refer to figure 2 , the soaking unit 20 includes a soaking frame body 201, a soaking pool 202, a soaking support roll 203, a soaking pressure roll 204, a supporting screw 205, a first turning roll 206, and a second soaking roll 207, and the first turning roll 206 is located in the soaking pool 202 On the top surface, there are two second soaking rollers 207, and the two second soaking rollers 207 are installed horizontally on one side of the soaking pool 202, and the soaking support roll 203 and the soaking pressure roll 204 are erected in the soaking pool through the adjustment assembly 60. Above 202, the yarn bypasses the soaking roller and can fully contact the smoothing agent in the soaking pool 202, and the soaked yarn is squeezed to a certain extent by the soaking support roller 203 and the soaking pressure roller 204, and the yarn is squeezed out. The extra smoothing agent on the line can avoid taking the extra smoothing agent out of the soaking ...

Embodiment 3

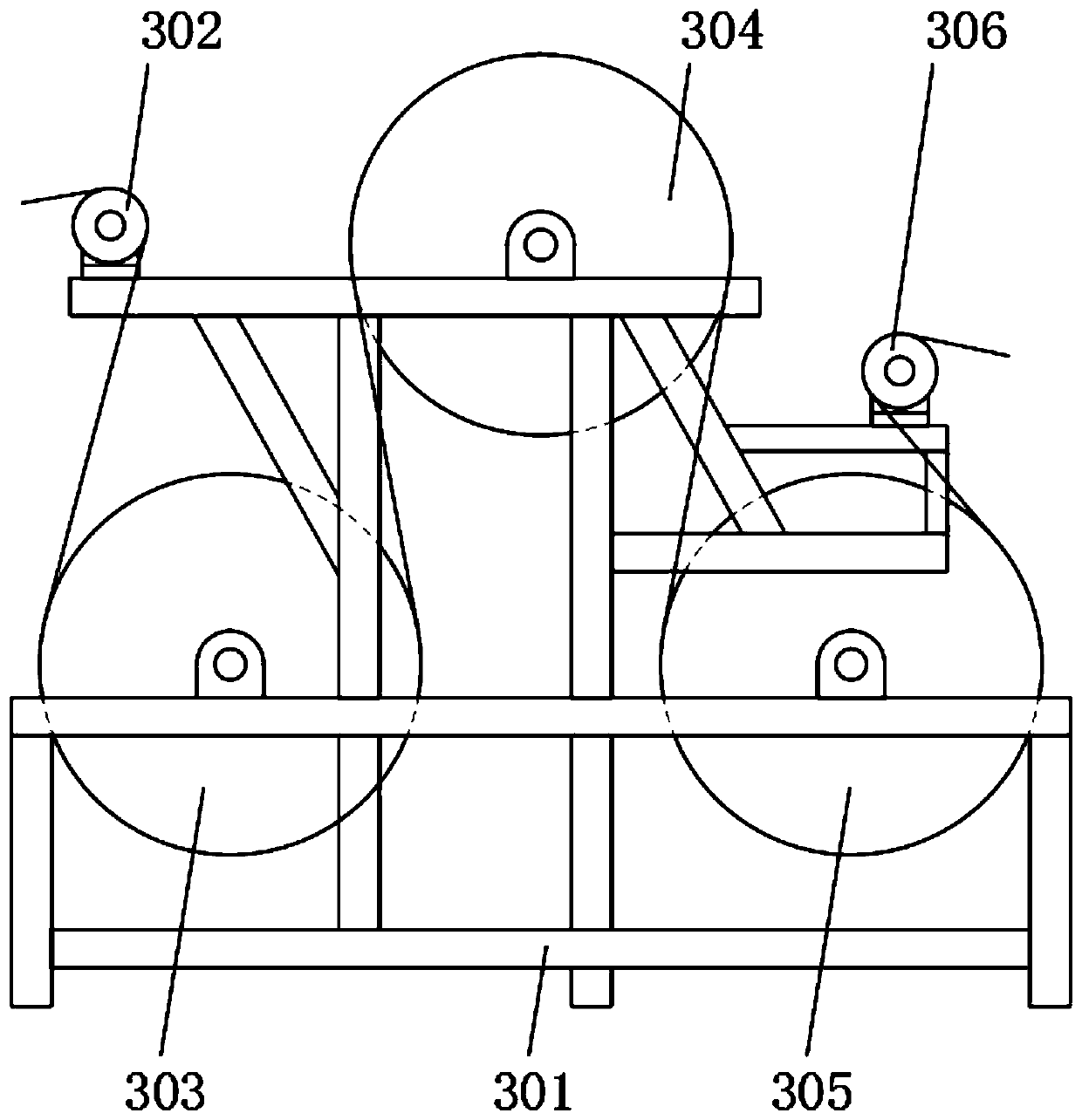

[0053] Embodiment three, refer to image 3 and Figure 6-7 , the comforting unit 30 includes a comforting frame body 301, a second turning roller 302, a first comforting cylinder 303, a second comforting cylinder 304, a third comforting cylinder 305, a third steering roller 306, a sprocket 307 and a drive The motor 308, the first comfort cylinder 303, the second comfort cylinder 304, and the third comfort cylinder 305 are distributed in a triangle on the comfort frame body 301, and sprockets 307 are installed on the ends, and the sprockets 307 and The drive motor 308 is connected in transmission, the drive motor 10 drives the sprocket 307 to rotate, and the first comfort cylinder 303, the second comfort cylinder 304 and the third comfort cylinder 305 are driven to rotate simultaneously through the transmission connection between the sprocket 307 and the chain, so as to avoid There is friction between the groove 309 and the relative movement of the yarn. The inside of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com