A continuous prefabricated asphalt pavement and its construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

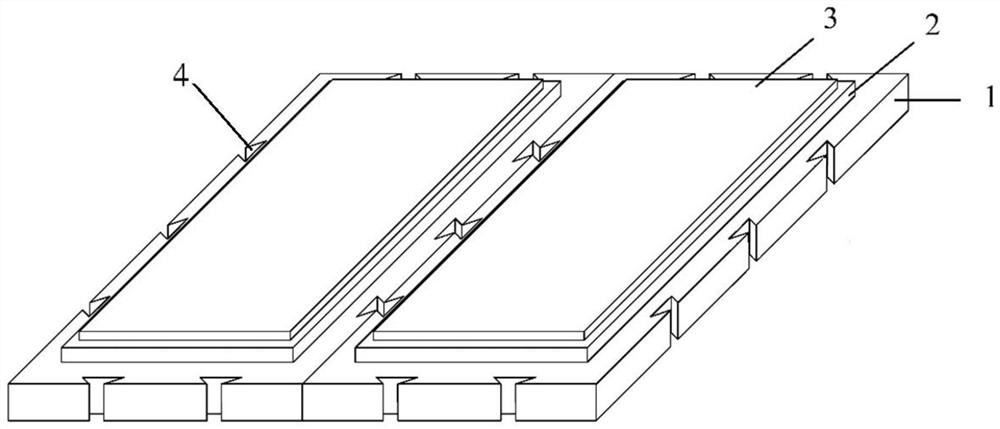

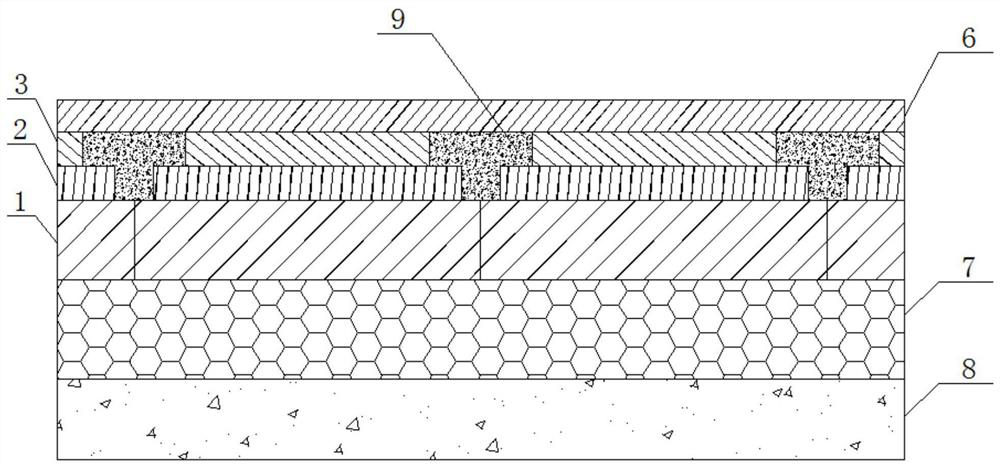

[0030] Embodiment 1: The continuous prefabricated asphalt pavement in this embodiment is composed of a prefabricated asphalt pavement slab, an upper layer 6, a cushion layer 7 and a soil foundation 8;

[0031] The cushion layer 7 is arranged on the upper surface of the soil foundation 8, the prefabricated asphalt road slab is arranged on the upper surface of the cushion layer 7, and the upper layer 6 is arranged on the upper surface of the prefabricated asphalt road slab and bonded by an emulsified asphalt adhesive;

[0032] The prefabricated asphalt road slab is composed of a plurality of prefabricated slab units; the prefabricated slab unit is composed of a base layer 1, a lower layer 2 and a middle layer 3; the lower layer 2 is arranged on the upper surface of the base layer 1 and bonded by an emulsified asphalt adhesive , the side of the lower layer 2 is set on the inner side of the side of the base layer 1, the middle layer 3 is set on the upper surface of the lower layer ...

specific Embodiment approach 2

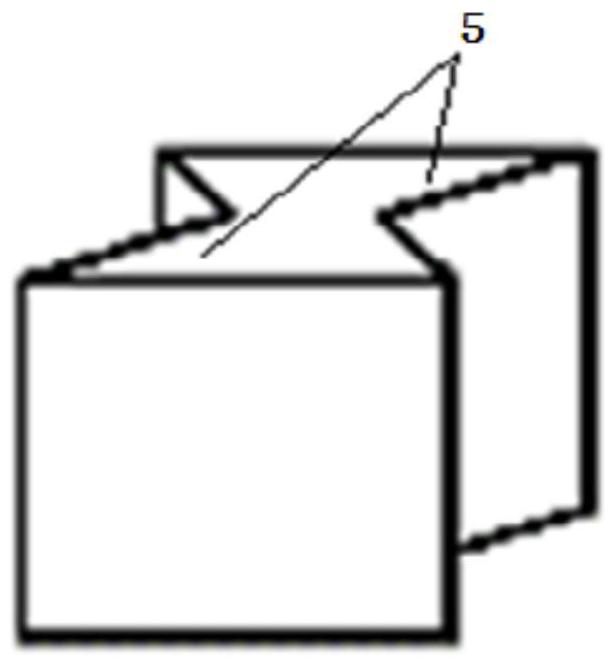

[0037] Specific Embodiment 2: The difference between this embodiment and Specific Embodiment 1 is that the double-tenon coupling block is composed of two tenons 5 with the same shape and matched with the tenon groove 4. One end of the tenon 5 is a larger end surface, and the other end is The smaller ends of the two mortises 5 are relatively fixed. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the tenon groove 4 is a trapezoidal groove, and the smaller bottom side of the tenon groove 4 is an opening. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com