Seepage-preventing blocking structure and method for screw hole of concrete shear wall

A technology of concrete shear wall and screw hole, which is applied in the direction of building construction, building maintenance, construction, etc., to achieve the effect of easy operation, fast construction speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

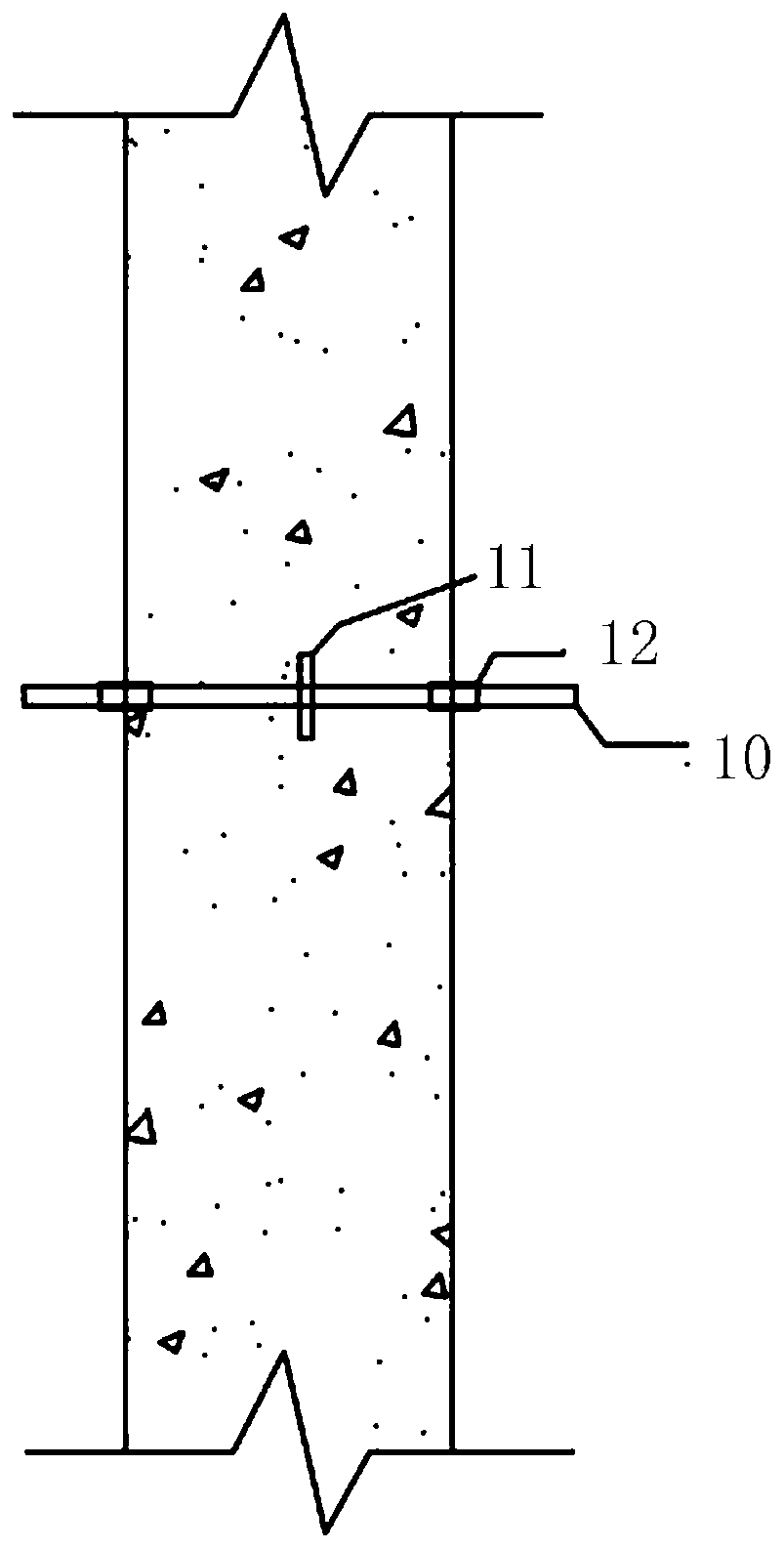

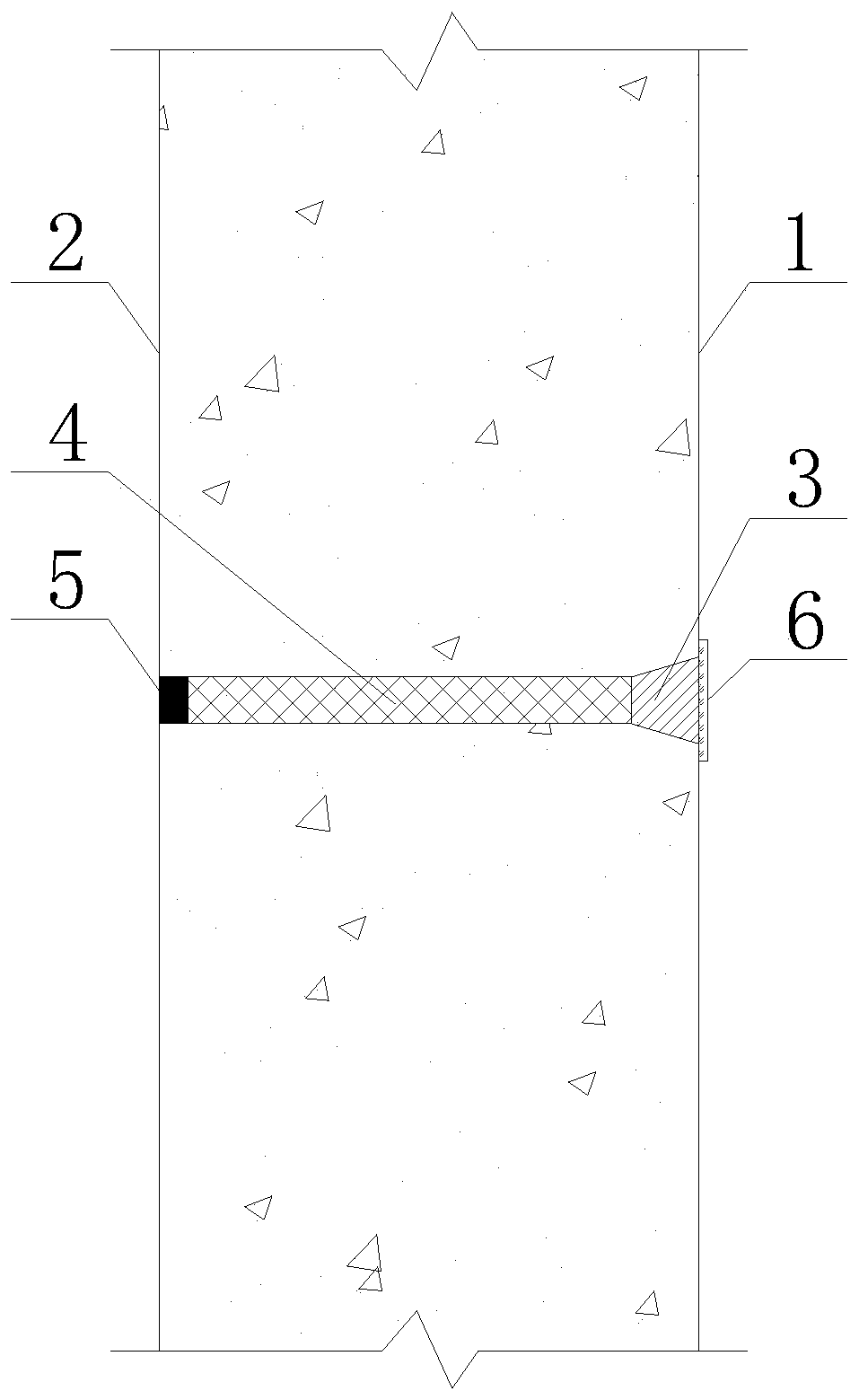

[0030] During the construction, the three-stage water-stop anti-tension screw is used to fix the formwork when the shear wall is poured. The anti-water structure is set on the anti-tension screw. The separate screws on both sides of the wall can be removed and reused. After the formwork is removed, it is removed. Pull screw at the end. This embodiment is aimed at the situation where a screw hole is formed between the concrete shear wall and the pull bolt, the screw hole includes the gap between the screw and the concrete shear wall or even a through hole is formed, in the concrete shear wall The outside 1 of the wall of the shear wall is provided with expansion holes around the pull screw, and the outside 1 of the wall of the shear wall refers to the water-facing surface of the wall. It should be noted that, in order to more clearly show the various components of the anti-seepage sealing structure, figure 2 The pull screw in the wall is not shown in the figure.

[0031] Suc...

Embodiment 2

[0036] This embodiment discloses an anti-seepage sealing method for screw holes in concrete shear walls. figure 2 The anti-seepage plugging method will be further explained. This anti-seepage plugging method comprises the steps:

[0037] Step 1. Check whether there is a screw hole that needs to be sealed between the pull bolt and the concrete shear wall. When there is a plastic pad at the end of the pull screw, remove the plastic pad to form an expansion on the concrete outer wall. hole; when the end of the pull screw is not provided with a plastic spacer, use a percussion drill to expand the hole on the outside of the wall 1 centered on the pull bolt to form an expanded hole, remove the PVC pipe in the expanded hole, and remove the PVC pipe in the hole. Clean up the debris;

[0038] In order to achieve a better anti-seepage effect, the depth of the expanded hole is not less than 20mm, and the diameter is not less than 30mm;

[0039] Step 2. Use a wire brush to clean up th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com