Inspection device for production of PTFE membrane material

An inspection device and membrane technology, which is used in measuring devices, analysis materials, and material analysis by optical means, etc., can solve the problem that PTFE membranes cannot enter the inspection site smoothly, are prone to wrinkles, and do not have the restrictive effect of inspecting PTFE membranes. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

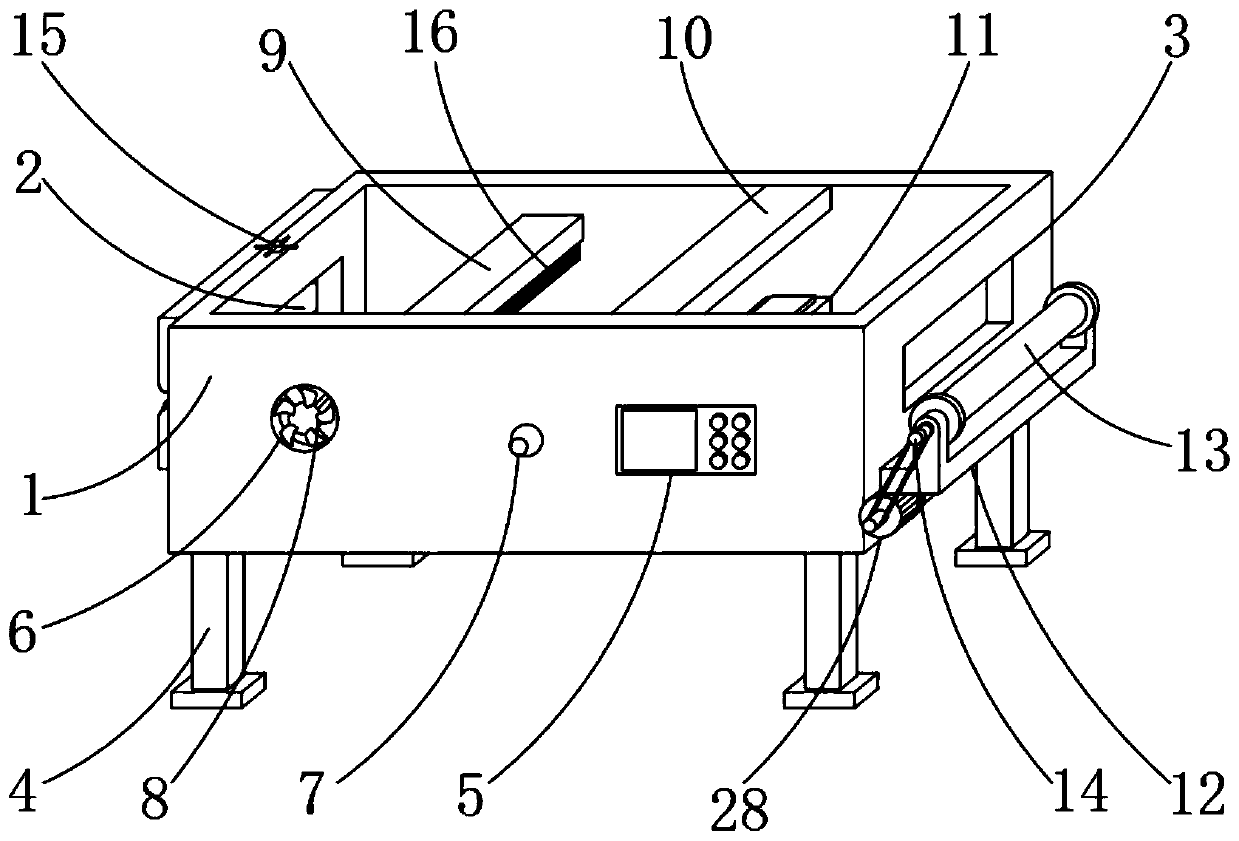

[0020] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of inspection device for PTFE film material production, comprises casing 1, and the bottom of casing 1 is fixedly connected with supporting leg 4, and supporting leg 4 is provided with four, and four supporting legs 4 are respectively arranged on At the four corners of the bottom of the box body 1, one side of the box body 1 is provided with a feed hole 2, and the other side of the box body 1 is provided with a discharge hole 3, and the feed hole 2 and the discharge hole 3 are arranged symmetrically. A first connecting piece 12 is fixedly connected to the bottom of the side of the box body 1 adjacent to the discharge hole 3, a first roller 13 is arranged on the upper side of the first connecting piece 12, and a motor 28 is fixedly installed on the bottom of the first connecting piece 12 , the first roller 13 is connected to the first connecting shaft 14 through an interference fit, the first c...

Embodiment 2

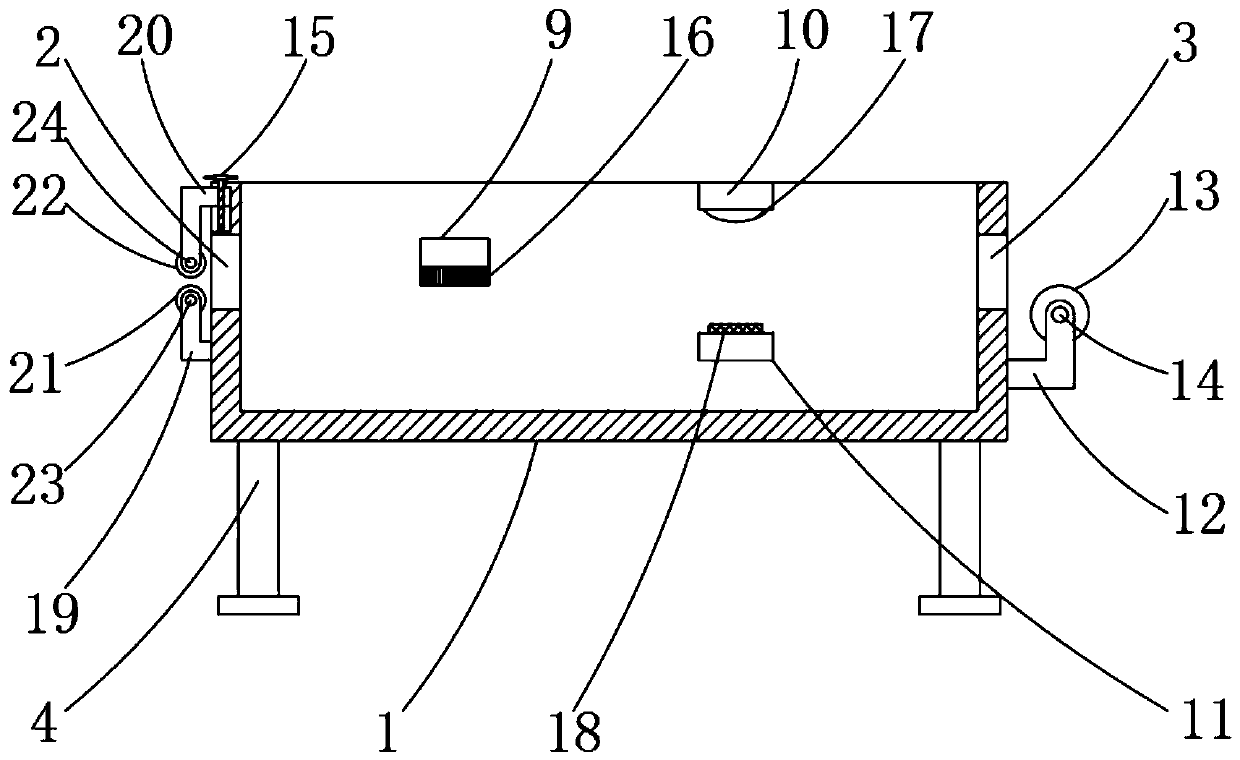

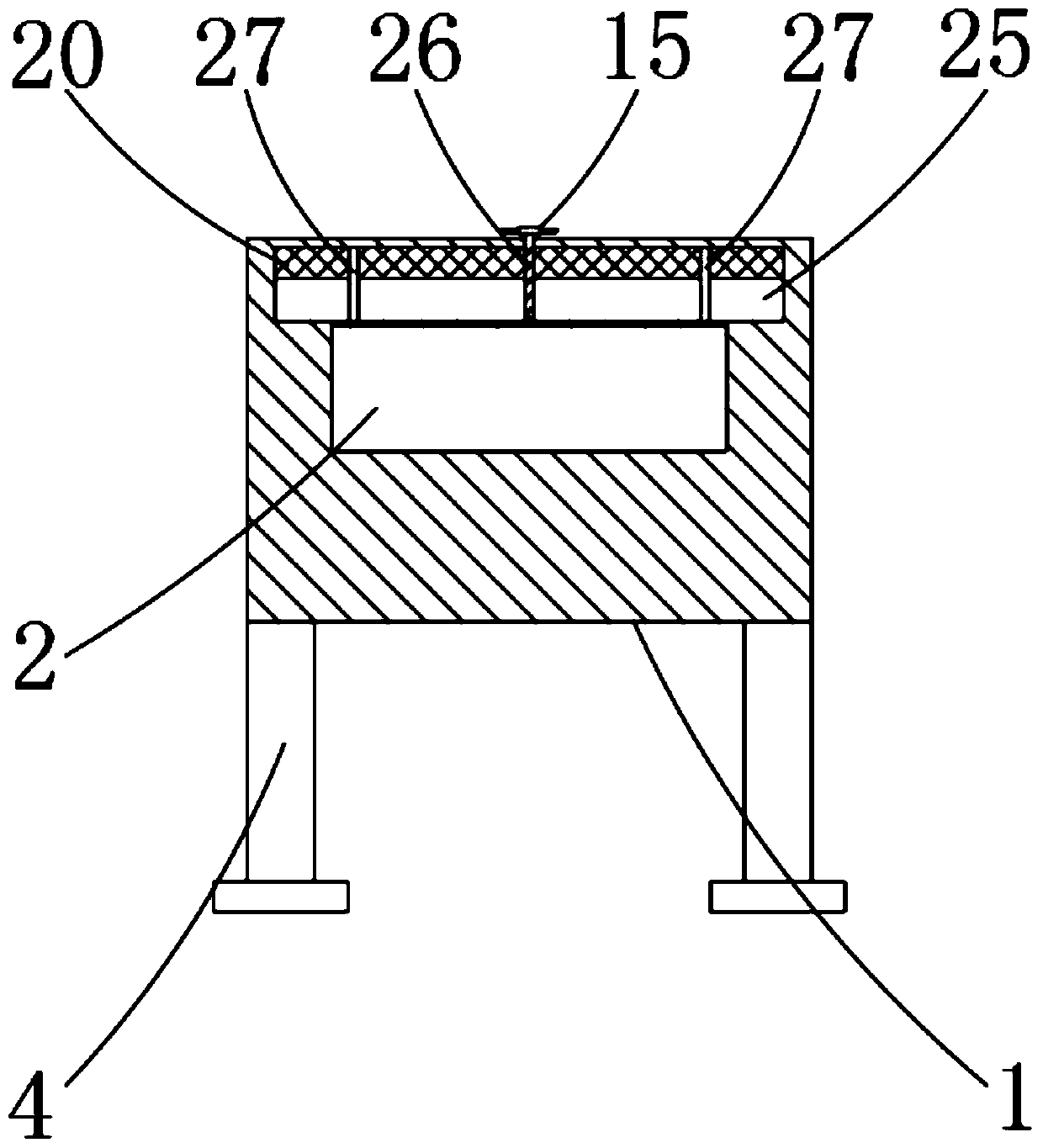

[0022] Such as Figure 1 to Figure 3 As shown, the same or corresponding components as in Embodiment 1 adopt the corresponding attachments of Embodiment 1 Figure marks, for the sake of brevity, only the differences from Embodiment 1 will be described below. The difference between the second embodiment and the first embodiment in: Such as figure 2 with image 3 As shown, the box body 1 is provided with a second connecting piece 19 and a third connecting piece 20 below and above the side close to the feeding hole 2, and the upper side of the second connecting piece 19 is provided with a second roller 21. The middle of the roller 21 runs through a second connecting shaft 23, the second connecting shaft 23 is connected to the second roller 21 through clearance fit, and the two ends of the second connecting shaft 23 are fixedly connected to the second connecting member 19, and the third connecting The lower side of the piece 20 is provided with a third roller 22, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com