Metering system for water-stabilized mixing materials

A metering system and material technology, which is applied in the field of metering systems for water-stabilized mixing materials, can solve the problems of unsuitable application in continuous working situations and limited application scope, and achieve the convenience of installing testing equipment, expanding the scope of quality monitoring, increasing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

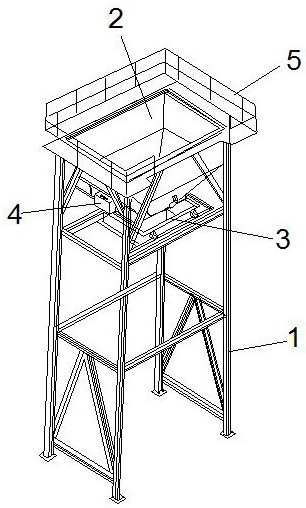

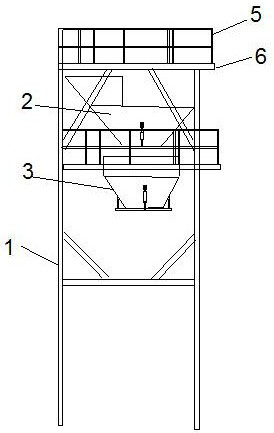

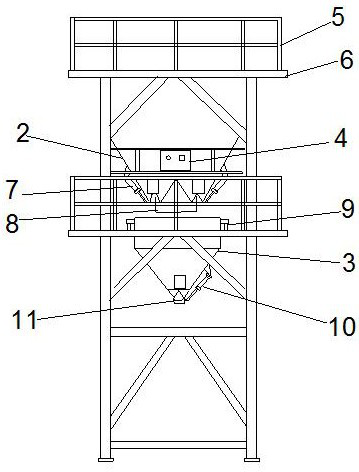

[0039] Such as Figure 1-3 As shown, a metering system for water-stabilized mixing materials includes a support frame 1 and a raw material bin 2, the top layer of the support frame 1 is provided with a raw material bin 2, and a pedal 6 is arranged around the raw material bin 2, and the pedal 6 Guardrails 5 are arranged around the side, and a metering bin 3 is correspondingly arranged below the raw material bin 2. A plurality of weight sensors are arranged on the upper edge of the metering bin 3, and a plurality of weight sensors are evenly distributed on the sides of the metering bin 3. Peripheral side; the metering bin 3 is connected with the support frame 1 through a weight sensor, and a pedal 6 is provided around the metering bin 3, and the pedal 6 is provided with a guardrail 5;

[0040] The side wall of the raw material bin 2 is provided with a first telescopic rod 7, and the shrinking end of the first telescopic rod 7 is connected with a feeding door 8, and the feeding d...

Embodiment 2

[0042] Such as Figure 4-6 Shown, on the basis of embodiment one, also comprise control module 4, described control module 4 comprises data acquisition module, data acquisition card, MCU; Described industrial computer obtains signal from data acquisition card by CAN driver, and described data The acquisition module and the data acquisition card are transmitted through wireless signals.

[0043] The data acquisition module includes a plurality of sensors 9, and the sensors 9 are weight sensors, and the weight sensors transmit signals with the data acquisition card through the wireless WiFi module.

[0044] The weight sensor performs chain communication between the wireless WiFi module and the data acquisition card. The WiFi transceiver converter set inside the MCU sends out a networking signal, and all the wireless WiFi modules of the weight sensor receive the networking signal and compare the networking signals. The strength of the signal is received by the wireless WiFi modu...

Embodiment 3

[0049] On the basis of Embodiment 1, a metering system for water-stabilized mixing materials adopts a metering method, comprising the following steps:

[0050] S1, the control module 4 sends a control signal to open the feeding door 8 of the raw material bin 2 through the first telescopic rod 7, and the material enters the inside of the metering bin 3;

[0051] S2, when the material in the metering bin 3 reaches a certain amount, close the feeding door 8 to stop adding materials. At this time, the load cell 9 weighs the metering bin 3 and the total weight in the metering bin 3 is transmitted to the MCU control board through the signal acquisition card ;

[0052] S3, through the control of the second telescopic rod 10 to open the discharge door 11, the material is continuously discharged from the metering bin 3. While the material is continuously being discharged, the weight sensor weighs the weight of the remaining materials in the granary and the metering bin 3 in real time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com