FRP anti-bending reinforcement design method based on component early warning wire theory

A design method and FRP board technology, applied in design optimization/simulation, electrical digital data processing, instruments, etc., can solve problems such as building safety hazards, bearing capacity degradation, and sudden damage, and achieve the effect of avoiding brittle damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

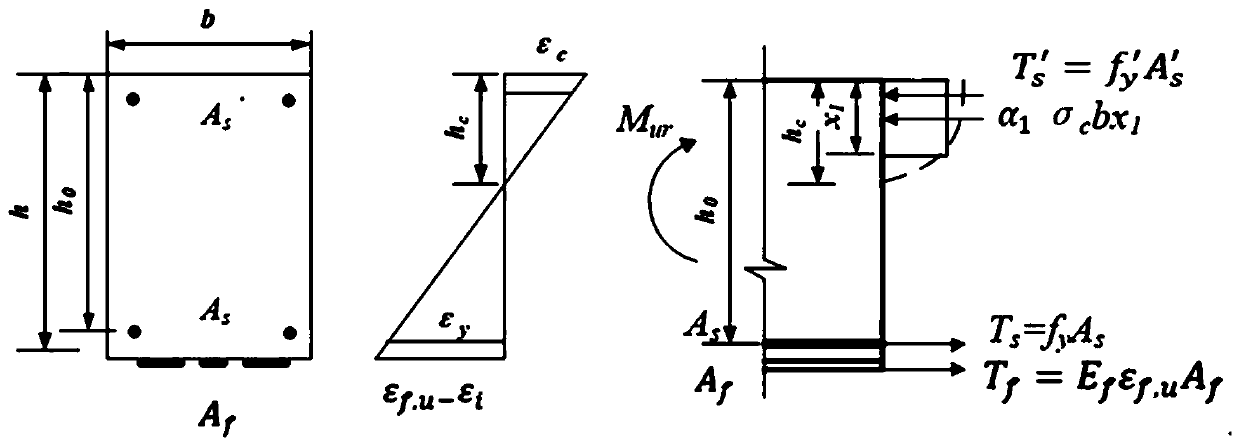

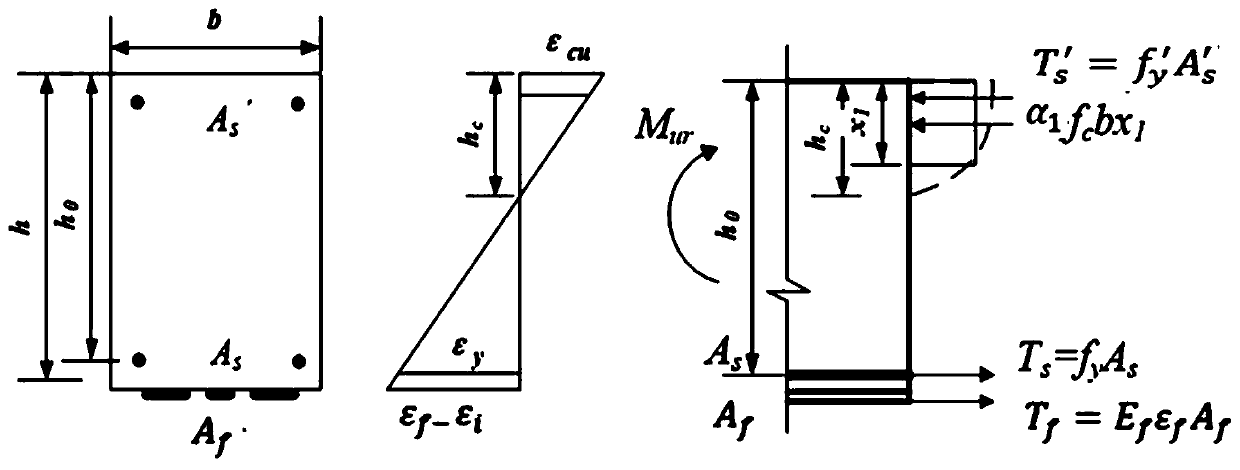

[0160] In this embodiment, a FRP flexural reinforcement design method based on component early warning wire theory includes the following processes:

[0161] 1) Evaluate the components that need to be reinforced, and determine the attribute parameters of the components to be reinforced;

[0162] 2) Calculate the existing bearing capacity M of the component y for

[0163] m y = f y A s (h 0 -0.5x 2 )-f' y A' s (x 2 -a s ) = f y A s h 0 (1-0.5ξ 2 )-f' y A' s (ξ( 2 h 0 -a s )

[0164] In the formula: s 2 is the height of the concrete compression zone of the equivalent rectangular stress pattern before reinforcement; ξ 2 is the height of the concrete relative compression zone of the unreinforced member.

[0165] 3) Analyze the failure mode and calculate the reinforcement amount of the FRP panel

[0166] In actual engineering, the beams that need to be strengthened are all beams with suitable reinforcement. After reinforcement, the failure mode is mostly the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com