Knife rest structure of simple automatic lathe

A technology of automatic lathes and tool holders, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of insufficient precision, low improvement cost, instability, etc., to improve processing accuracy, reduce labor costs, smooth control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

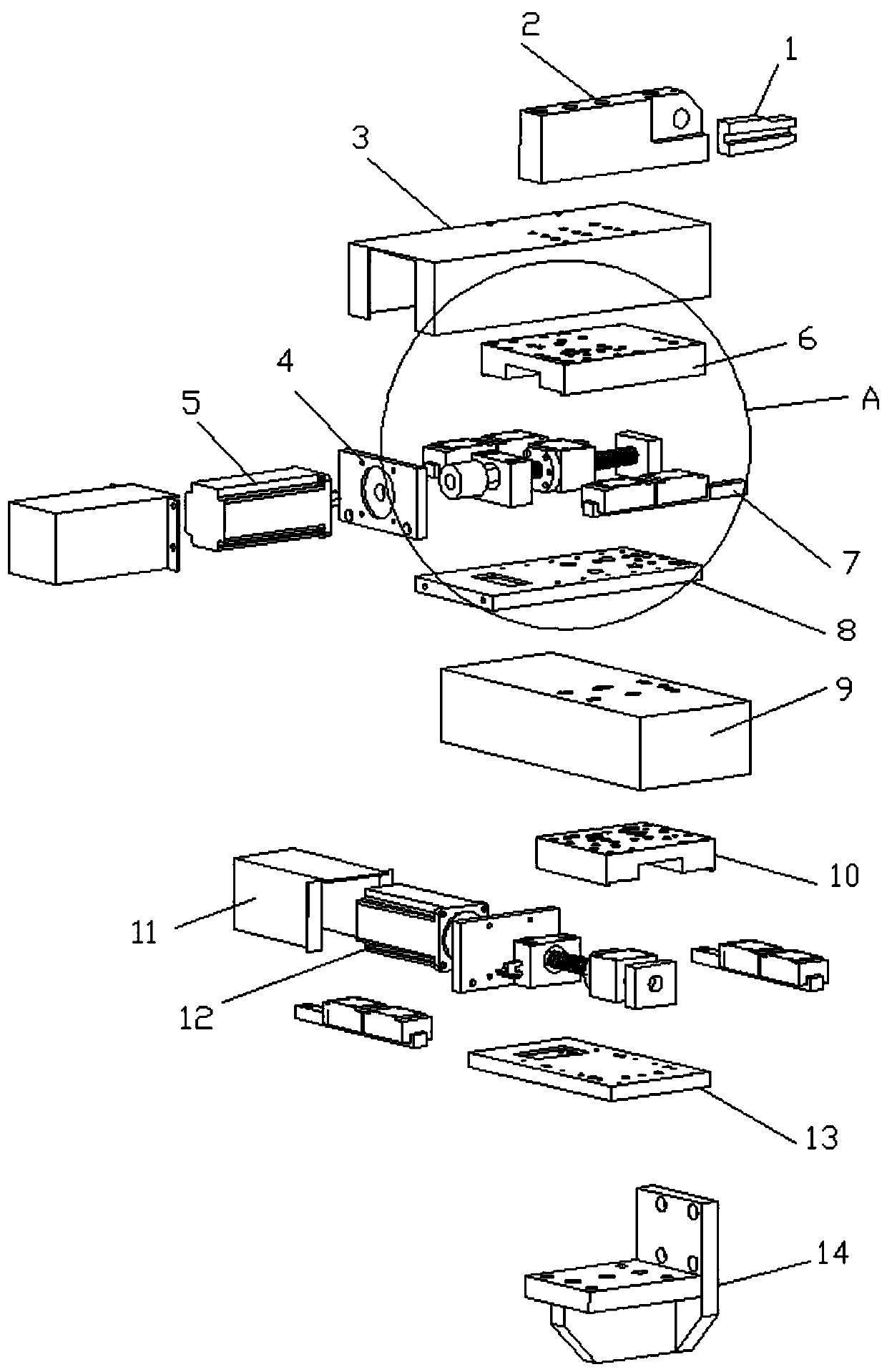

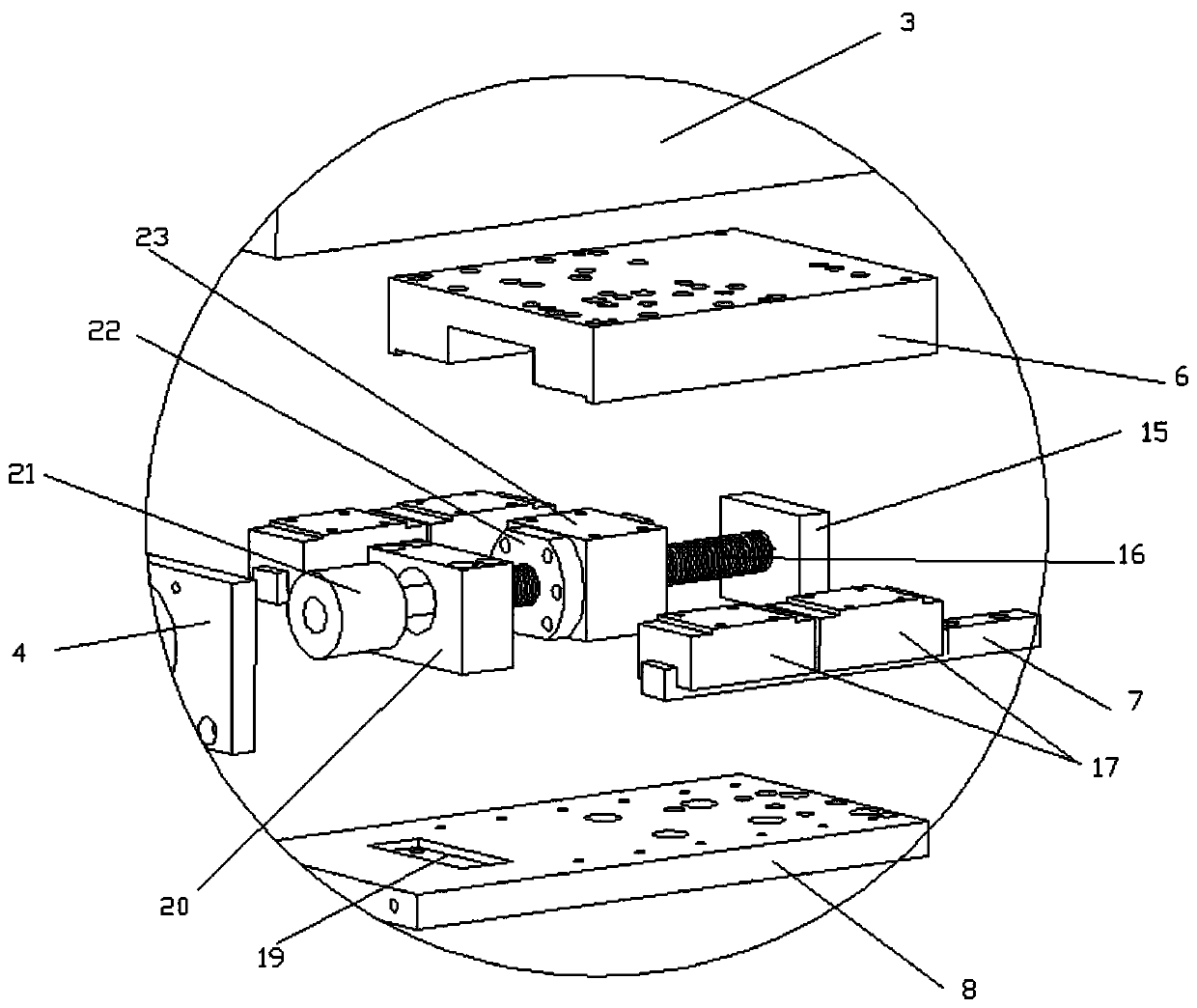

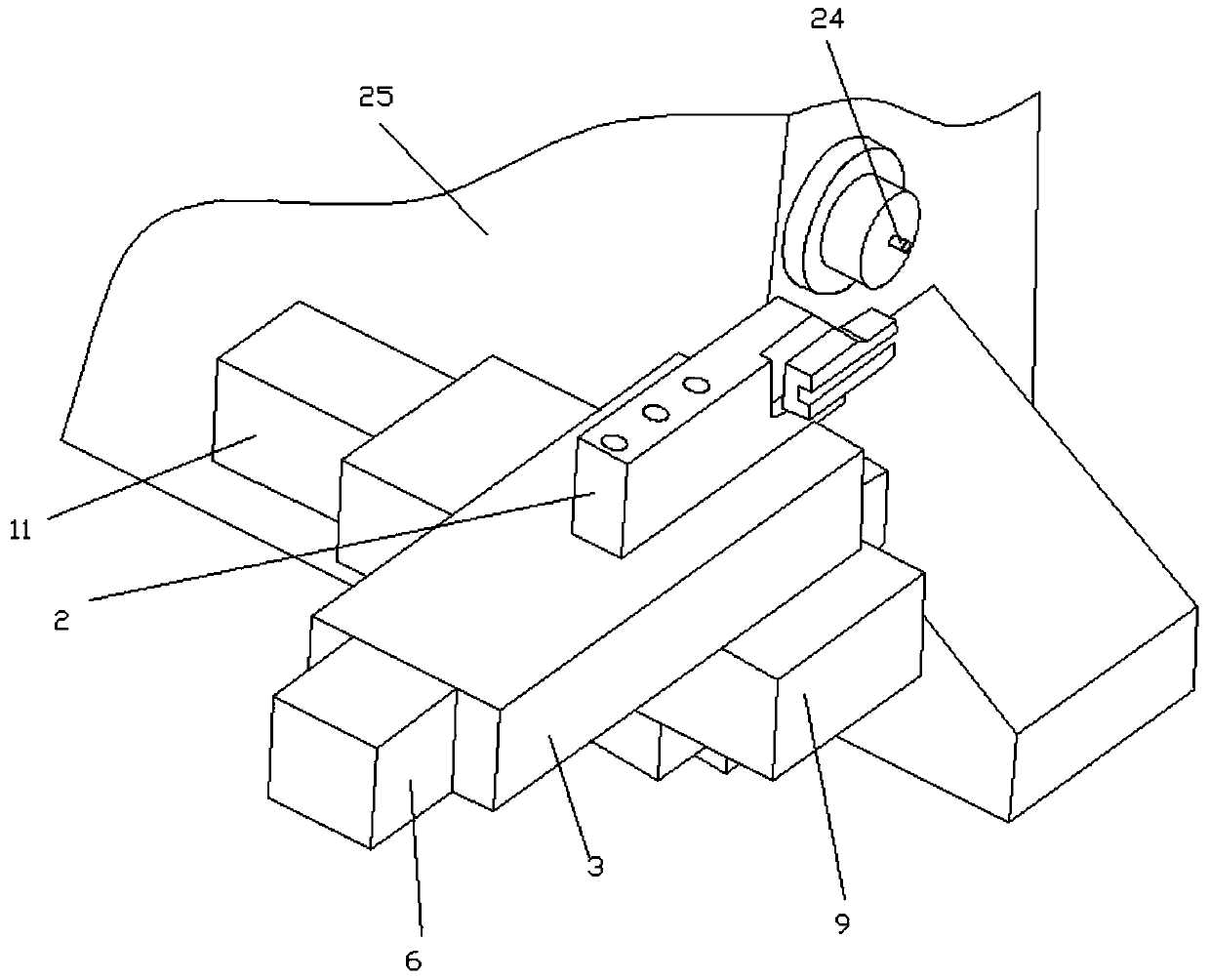

[0023] Such as Figure 1-3 As shown, the tool holder structure of a simple automatic lathe of the present invention includes an axial screw pushing mechanism, a radial screw pushing mechanism, a turning knife fixing mechanism and a fixed base 14; the axial screw pushing mechanism is fixed by the fixed base 14 On the side of the lathe, the radial screw pushing mechanism is connected with the axial screw pushing mechanism and controlled by it to move along the axial direction of the parts processed by the lathe; the turning knife fixing mechanism is connected with the radial screw pushing mechanism and controlled by it to move along the lathe The radial movement of the parts, the turning tool fixing mechanism is used to fix the turning tool.

[0024] The radial screw push mechanism includes a radial control motor 5, a radial motor shield, a radial motor seat plate 4, a radial fixing plate 8, a radial transmission screw 16, a radial slider, a radial slide table 6, a radial Slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com