Chain mold injection molding technology of polystyrene plastic granules

A technology of polystyrene plastic and injection molding technology, which is applied in the field of plastic processing, and can solve the problems of plastic particles not fixed in shape, unfavorable for sales, fine processing, and inconsistent specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

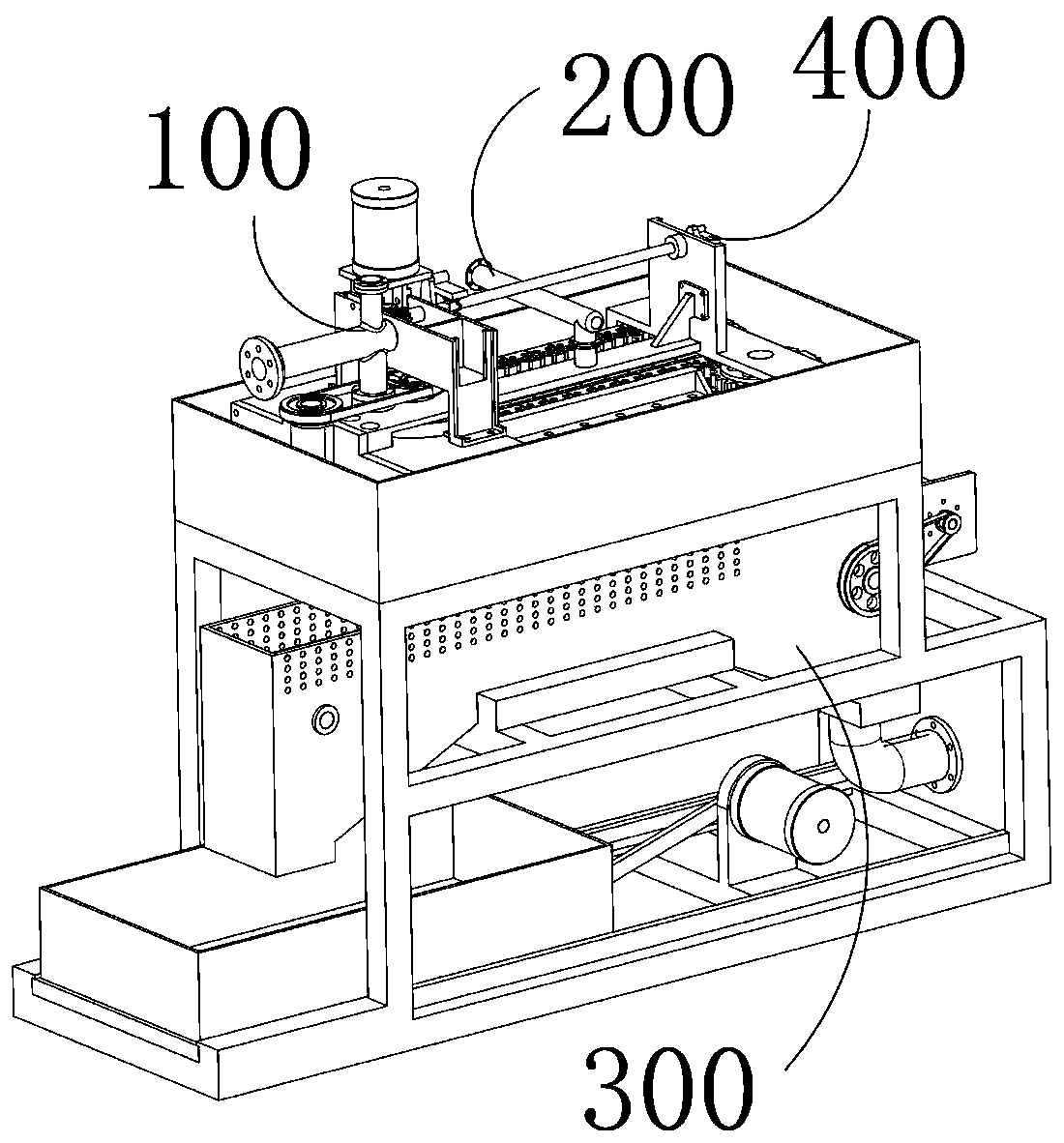

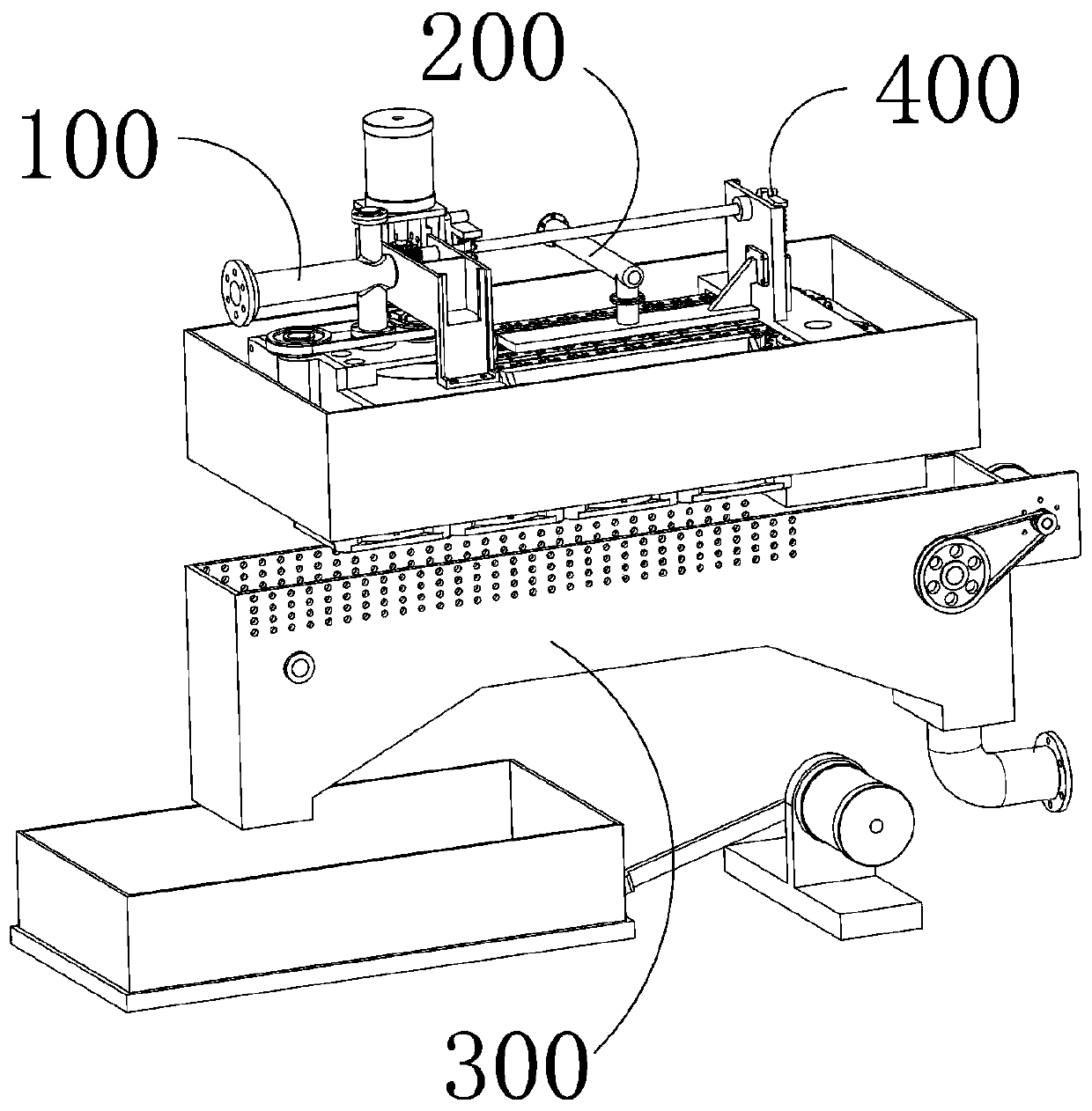

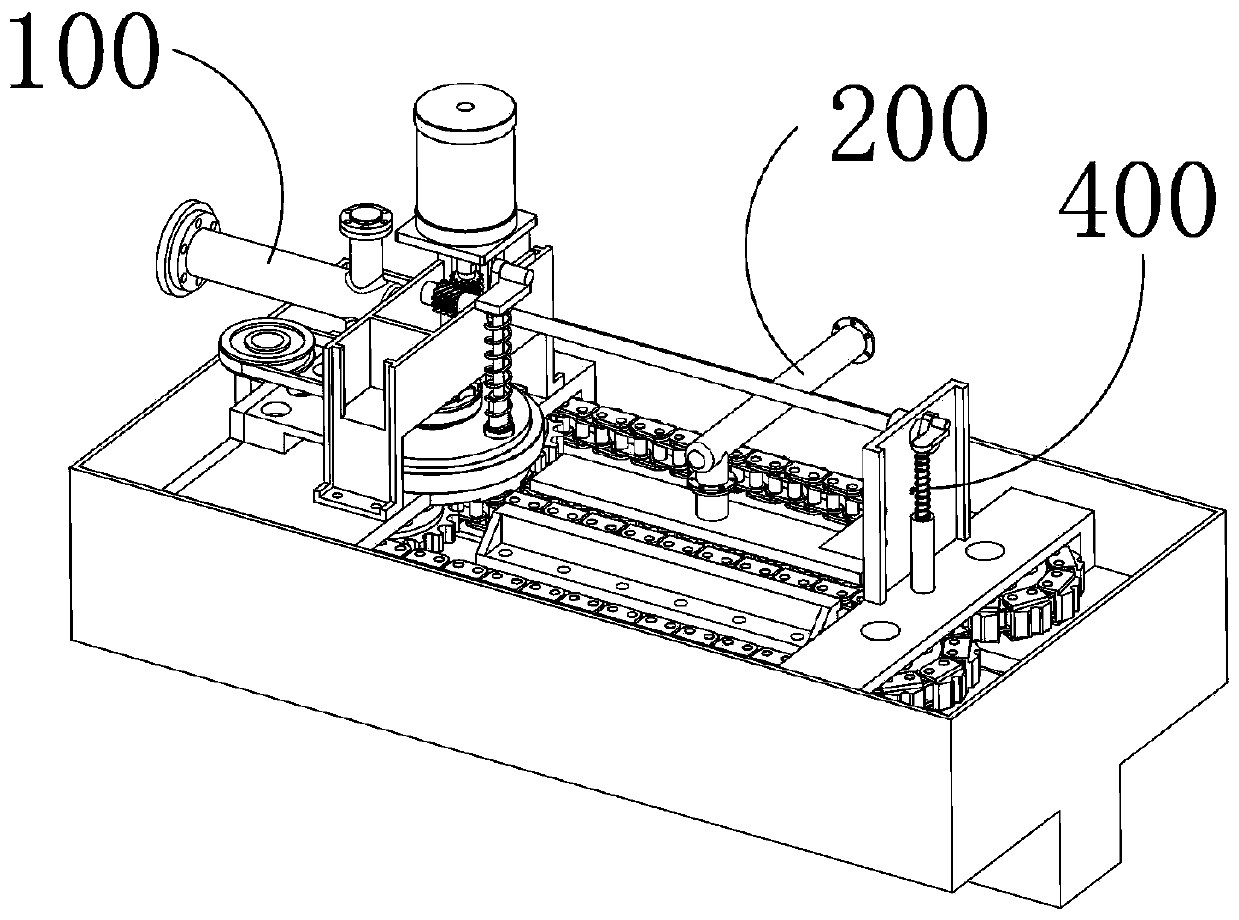

[0087] The chain mold injection molding process of polystyrene plastic granules, its steps are:

[0088] (1) Plastic granule forming stage;

[0089]S1: the mold device 100 installed in the cooling water tank receives the plastic and performs granular shaping treatment on it;

[0090] The mold device 100 includes a feeding mechanism 110, a mold mechanism 120, and an intermittent drive mechanism 130. The mold mechanism 120 includes a mold body 121, an upper closing cover 122, and a lower closing cover 123. The upper / lower closing covers are arranged horizontally. A vertical plate 1 is arranged between the bottom of the lower closed cover 123 and the bottom of the cold water tank, and the lower closed cover 123 is fixed on the bottom of the cooling water tank through the vertical plate 1, and the bottom of the upper closed cover 122 is provided with a vertical plate 2 and The upper closed cover plate 122 is fixed on the upper end surface of the lower closed cover plate 123 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com