Cyclic chained die for plastic particle forming

A technology of plastic granules and molds, which is applied in the field of plastic processing, can solve the problems of non-uniform specifications, unstable shape of plastic granules, unfavorable sales and fine processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

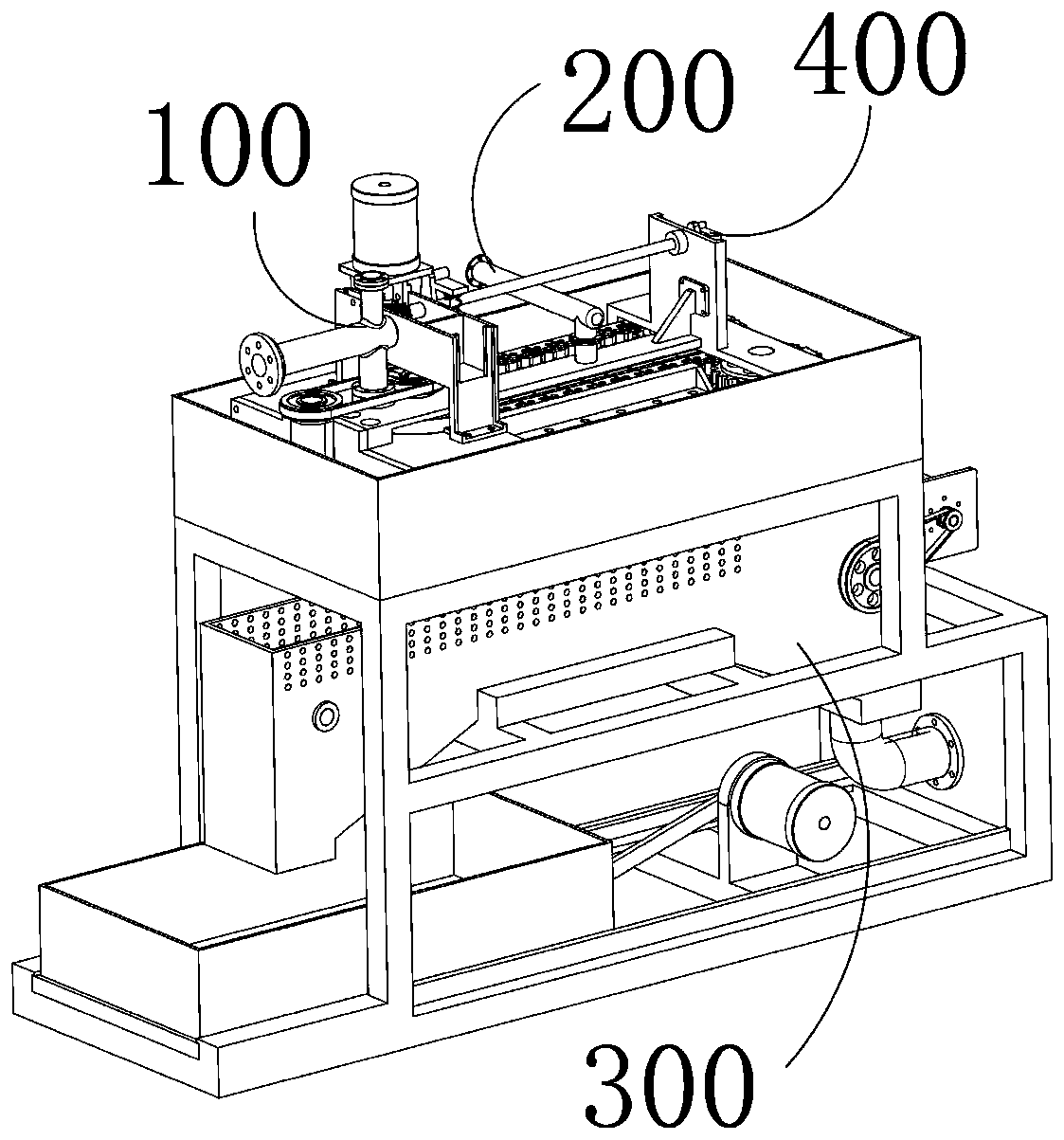

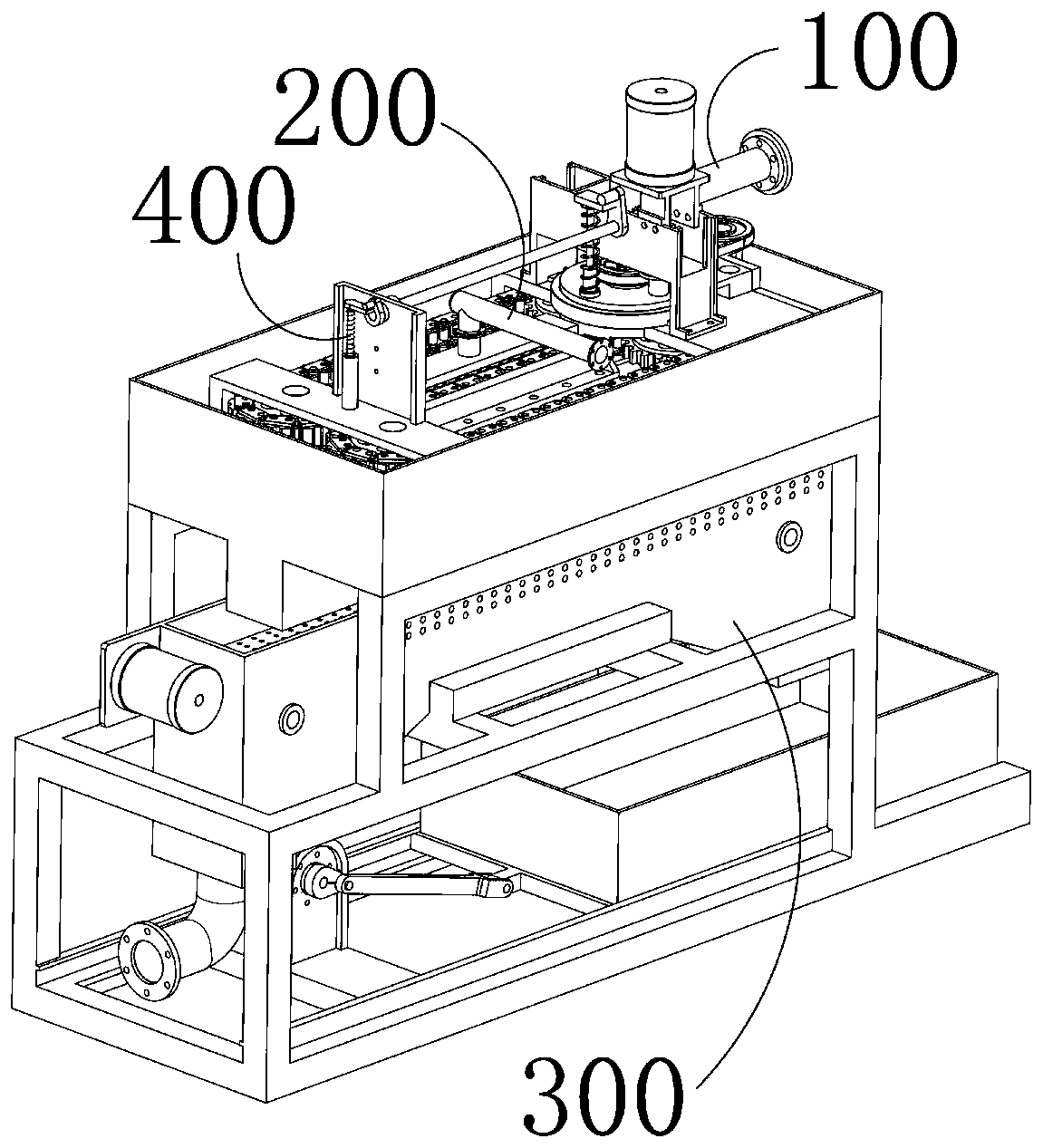

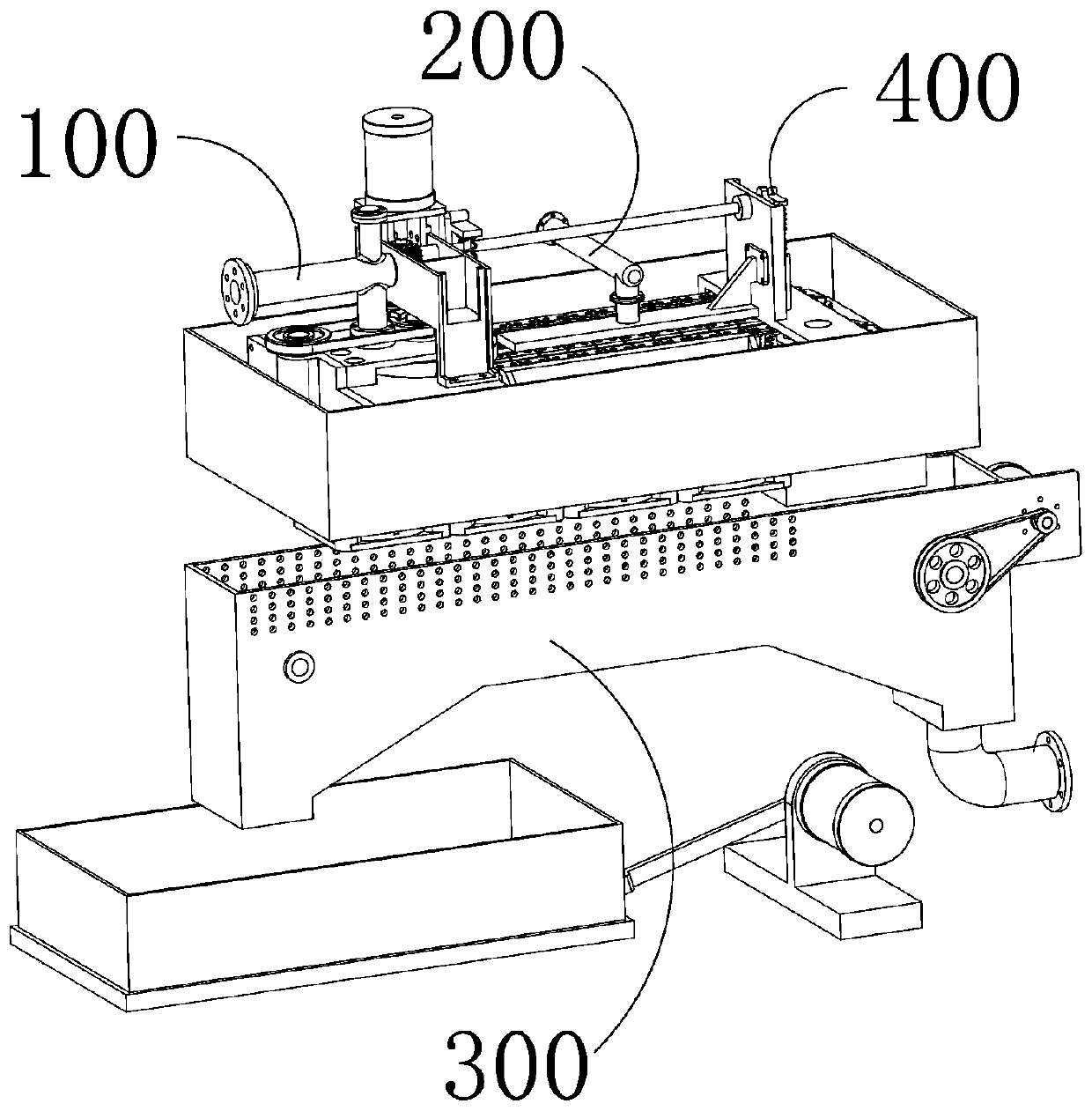

Image

Examples

Embodiment Construction

[0084]The present invention has the advantage of receiving molten plastic and granulating it in that it can obtain plastic granules that meet the production requirements. During the melting and molding conveying process, the heating element arranged outside the mold body will keep the plastic molten in the mold body. state; during the cooling molding process, the cooling water is in contact with the molten plastic in the form of spraying, which can increase the contact area between the two, and the cooling water is also cooled by flowing water, and the cooling effect is better; during the output of plastic particles, Air-dry the moisture on the surface of the plastic granules through the fan, which reduces the heat consumption required for the melting of the plastic granules in the subsequent utilization process, and also facilitates the long-term storage of the plastic granules; in addition, after the granules are shaped in the mold body In the process of dropping molten plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com