A process for producing low-sulfur marine fuel oil by external circulation wax oil fixed-bed hydrotreating

A hydrotreating and fixed bed technology, applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of poor marine fuel oil economy, high operating severity and high operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

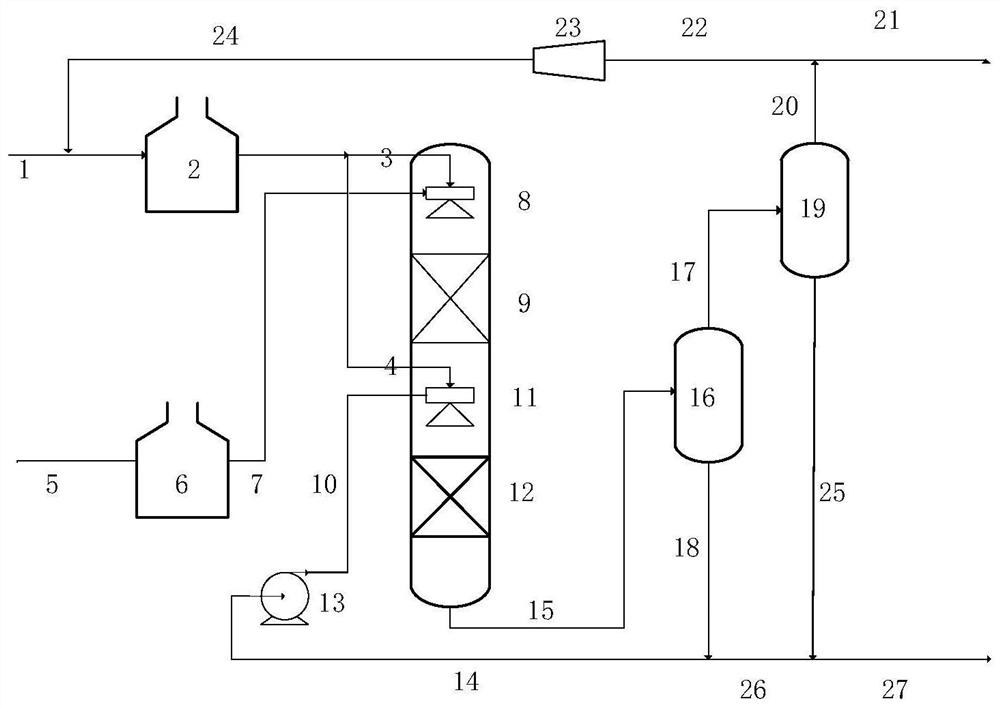

Method used

Image

Examples

Embodiment 1

[0035] The average temperature of the reactor is 355°C, and the overall space velocity is 0.2h -1 , Reaction operating pressure 6MPa, hydrogen oil volume ratio 200 (V / V).

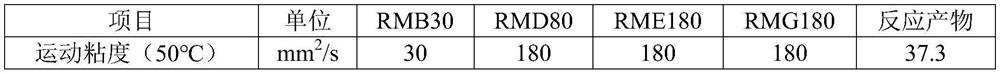

[0036] The properties of the product and the properties of several marine fuel oils are shown in the table below:

[0037]

[0038]

[0039] It can be seen that except for the viscosity that does not meet the RMB30 marine fuel oil standard, other indicators meet the above four fuel oil standards.

Embodiment 2

[0041] The average temperature of the reactor is 370°C, and the overall space velocity is 1h -1 , Reaction operating pressure 6MPa, hydrogen oil volume ratio 400 (V / V).

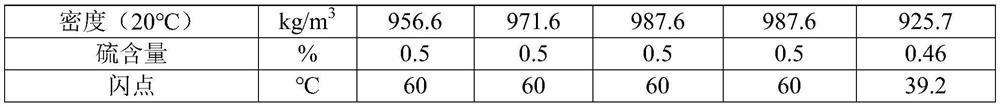

[0042] The properties of the product and the properties of several marine fuel oils are shown in the table below:

[0043] project unit RMB30 RMD80 RME180 RMG180 reaction product Kinematic viscosity (50℃) mm 2 / s

[0044] According to the comparison of the four main indicators of the reaction product and the four fuel oils, the fuel oil produced under the process conditions meets the standard requirements.

Embodiment 3

[0046] The average temperature of the reactor is 380°C, and the overall space velocity is 2h -1 , Reaction operating pressure 6MPa, hydrogen oil volume ratio 600 (V / V).

[0047] The properties of the product and the properties of several marine fuel oils are shown in the table below:

[0048] project unit RMB30 RMD80 RME180 RMG180 reaction product Kinematic viscosity (50℃) mm 2 / s

[0049] According to the comparison of the four main indicators of the reaction product and the four fuel oils, the fuel oil produced under the process conditions meets the standard requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com