High-alcoholic-strength high-bitter-substance hops-flavor IPA beer and preparation method thereof

A technology of alcohol content and bitterness, which is applied in the field of hoppy IPA beer, can solve the problems of uncomfortable and irritating aroma, bitterness and astringency, and achieve the effect of simple and easy brewing method, strong fruity aroma and high alcohol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

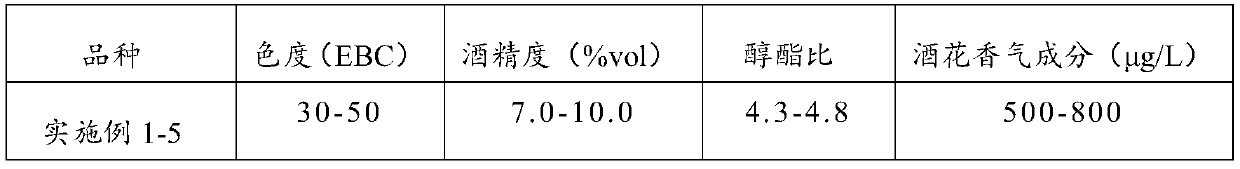

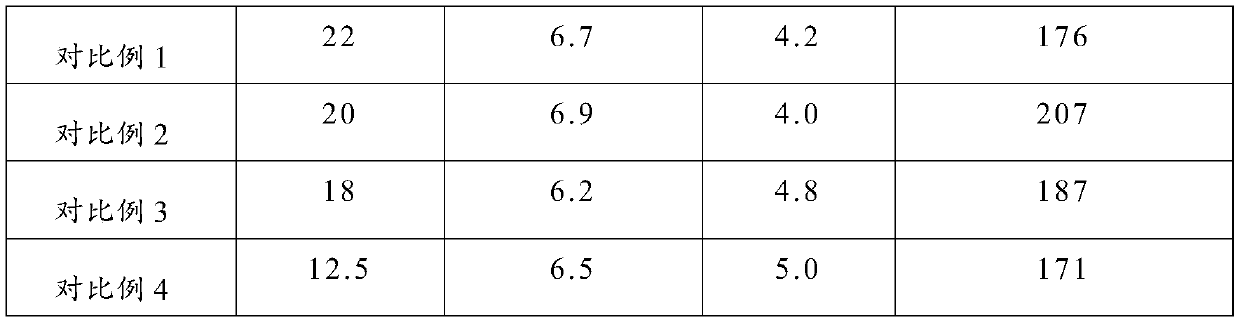

Examples

preparation example Construction

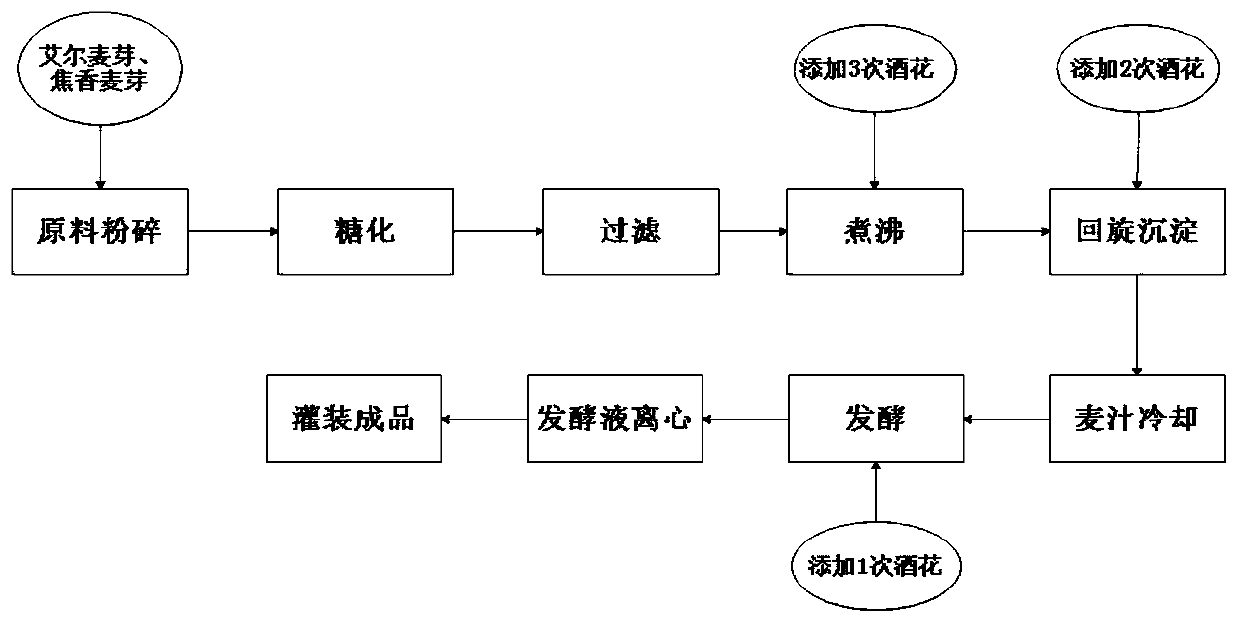

[0033] The embodiment of the present invention also provides a kind of preparation method of hop fragrance IPA beer, comprises the following steps:

[0034] S1: Choose ale malt and caramel malt as the main raw materials. After crushing the raw materials, add them to the mash pot, then add water, and mix them at a ratio of 1:3-1:4. Carry out two-stage saccharification process;

[0035] In the above steps, the ratio of material to water is mixed according to the ratio of 1:3-1:4, wherein the ratio can be selected as 1:3, 1:4 or any value within the limited range; the method of two-stage saccharification is selected. , including the first stage of saccharification at 48-52°C for 20-40 minutes and the second stage of saccharification at 63-68°C for 60-70 minutes. The advantage of the two-stage saccharification method is that it can ensure the full decomposition of starch.

[0036] S2: After the saccharification is completed, after the iodine test is passed, the temperature is rai...

Embodiment 1

[0045] Such as figure 1 Shown, the preparation method of the hop fragrance IPA beer of high alcohol content, high bitter quality, specifically comprises the following steps:

[0046] Ayer malt (accounting for 82% of the total amount of raw materials), caramel malt (accounting for 18% of the total amount of raw materials) and water are used as the main raw materials. Mix in the same ratio, keep warm at 48°C for 40 minutes, then raise the temperature to 63°C and keep warm for 70 minutes;

[0047] After the saccharification is completed, after passing the iodine test, the temperature is raised to 78°C to filter the wort and wash the tank to obtain the wort;

[0048] During the wort boiling process, add hop Cascade or Simco 3 times, add hop Cascade or Simco respectively at the initial boiling, 50 minutes of boiling, and 60 minutes of final boiling, and the addition amount is respectively 3kg / kL, 4kg / kL and 7kg / kL, wort whirlpool sedimentation after boiling, in the whirlpool sedi...

Embodiment 2

[0052] Such as figure 1 Shown, the preparation method of the hop fragrance IPA beer of high alcohol content, high bitter quality, specifically comprises the following steps:

[0053] Ayer malt (accounting for 84% of the total amount of raw materials), caramel malt (accounting for 16% of the total amount of raw materials) and water are used as the main raw materials. Mix in the same ratio, keep warm at 50°C for 30 minutes, then raise the temperature to 65°C and keep warm for 65 minutes;

[0054] After the saccharification is completed, after passing the iodine test, the temperature is raised to 78°C to filter the wort and wash the tank to obtain the wort;

[0055] During the wort boiling process, add hop century or spring 3 times, add hop century or spring 1 time respectively at the initial boiling, 50 minutes of boiling, and 65 minutes of final boiling, and the addition amount is 4kg / kL, 5kg / kL and 6kg respectively / kL, after the boiling is completed, carry out whirlpool pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com