Oil net structure and range hood

An oil net and air net technology, applied in the field of oil net structure and range hood, can solve the problems of poor condensation effect, unfavorable and rapid removal of oil fume, slow air inlet speed, etc., so as to improve the condensation effect, improve the oil fume separation effect, improve The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

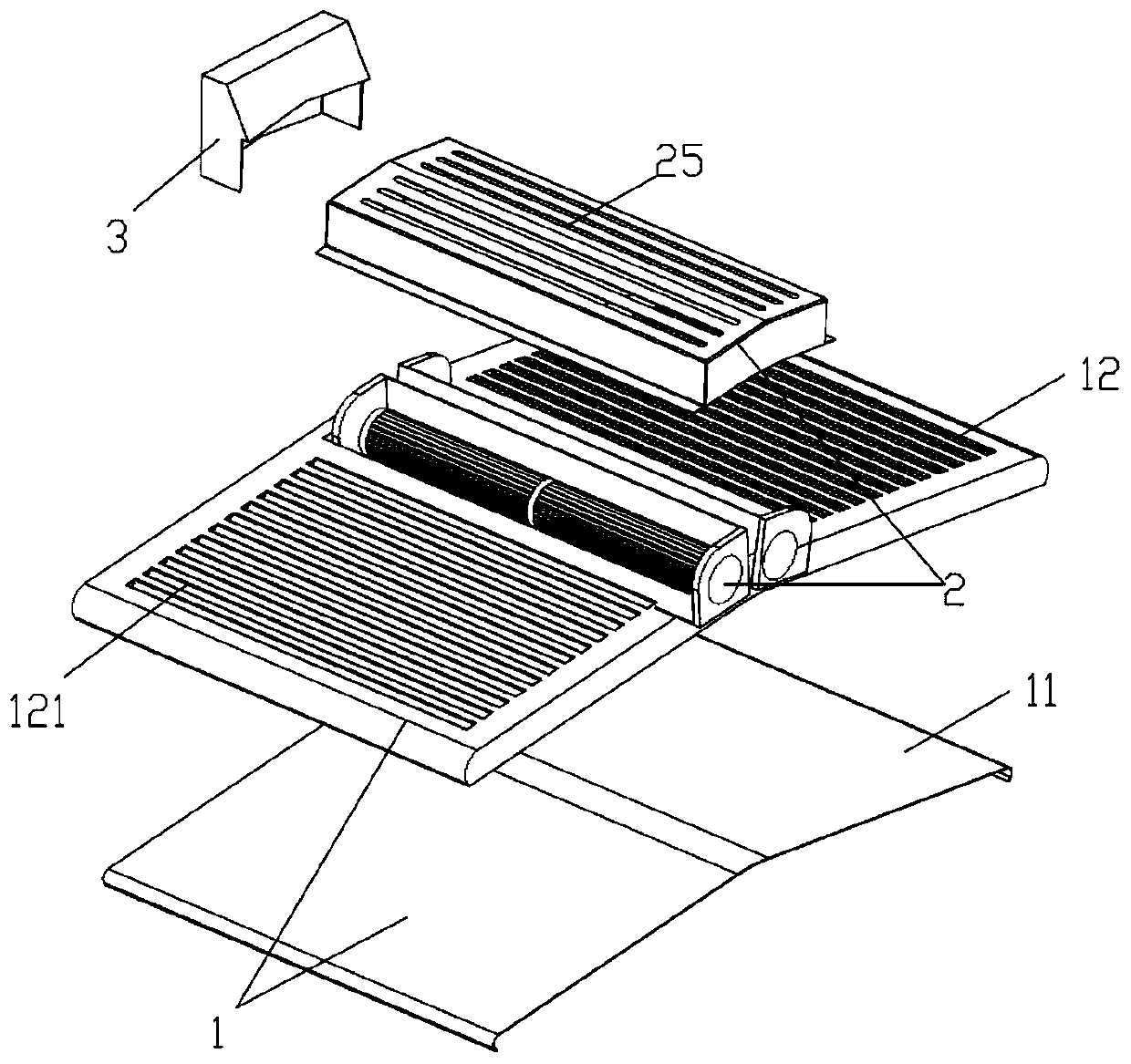

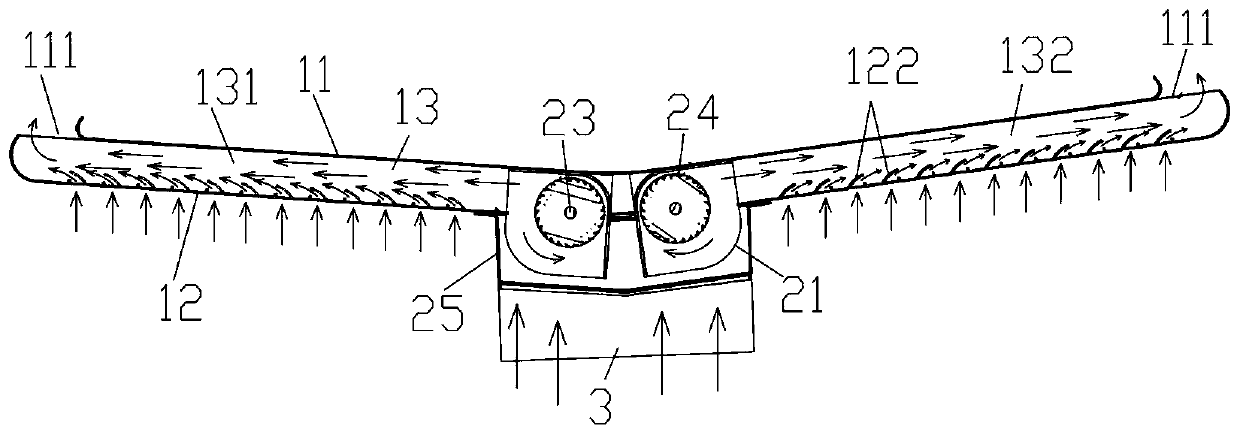

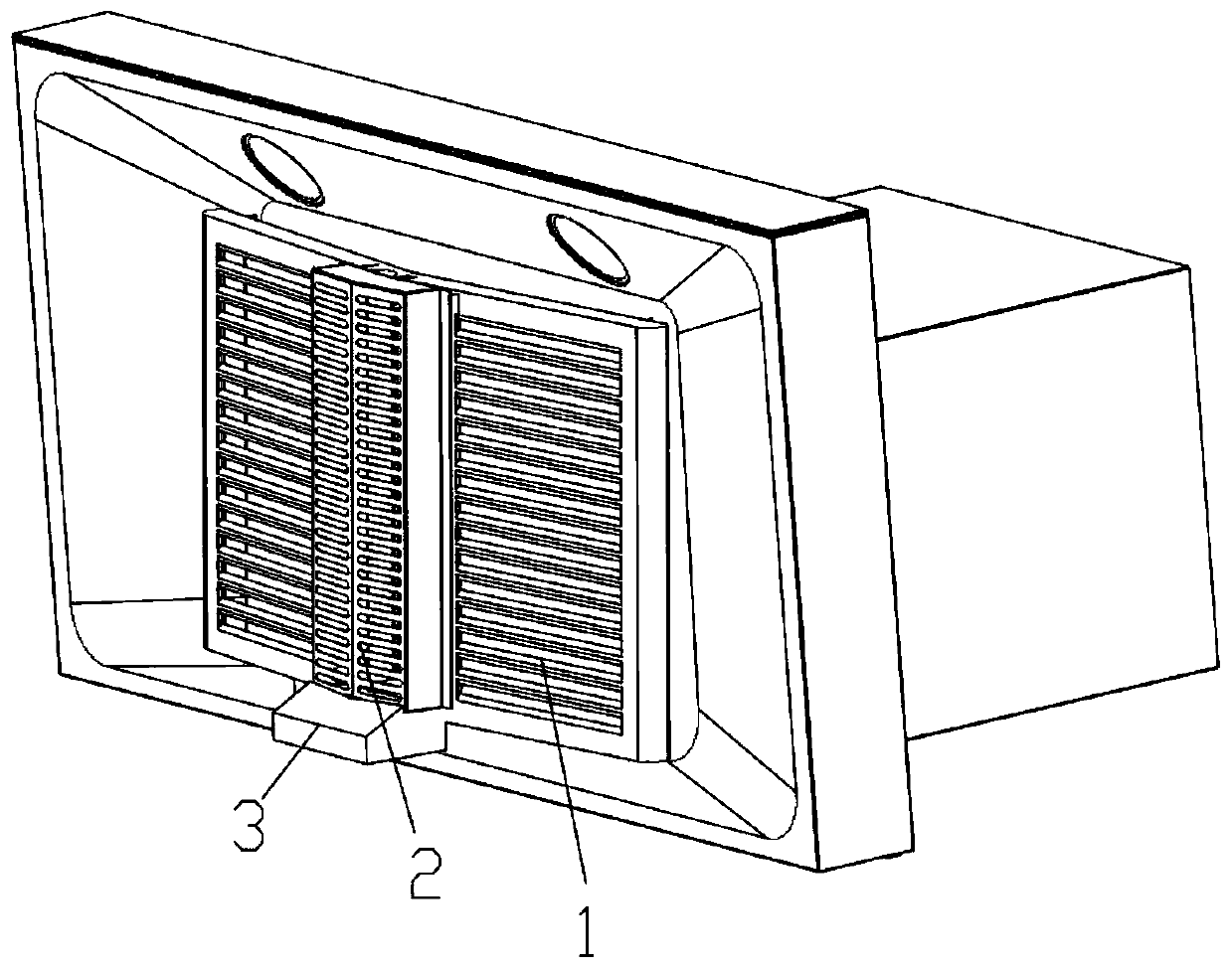

[0021] See attached Figure 1-3 , a kind of oil screen structure, including the upper condensing plate 11 and the lower air net 12 that form the air net group 1, the lower air net 12 is provided with an air inlet end 121, and the left and right sides of the upper condensing plate 11 are provided with air outlet end 111, there is a gap between the upper condensing plate 11 and the lower air net 12 to form a flow channel 13 from the air inlet end to the air outlet end, and the air blower 2 is also arranged on the air net group 1, so The air outlet of the blower device 2 is located on the flow channel 13 and blows air to the air outlet end 111 to increase the wind speed and negative pressure of the flow channel 13. By forming the structure of the lower air net 12 and the upper condensation plate 11, the lower air net 12 It can block the heat radiation while entering the wind, so that the temperature of the upper condensing plate 11 is not high, and the condensation effect is impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com