Tunable film bulk acoustic resonator

A thin-film bulk acoustic wave and resonator technology, applied in the field of resonators, can solve problems such as the impact of FBAR performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

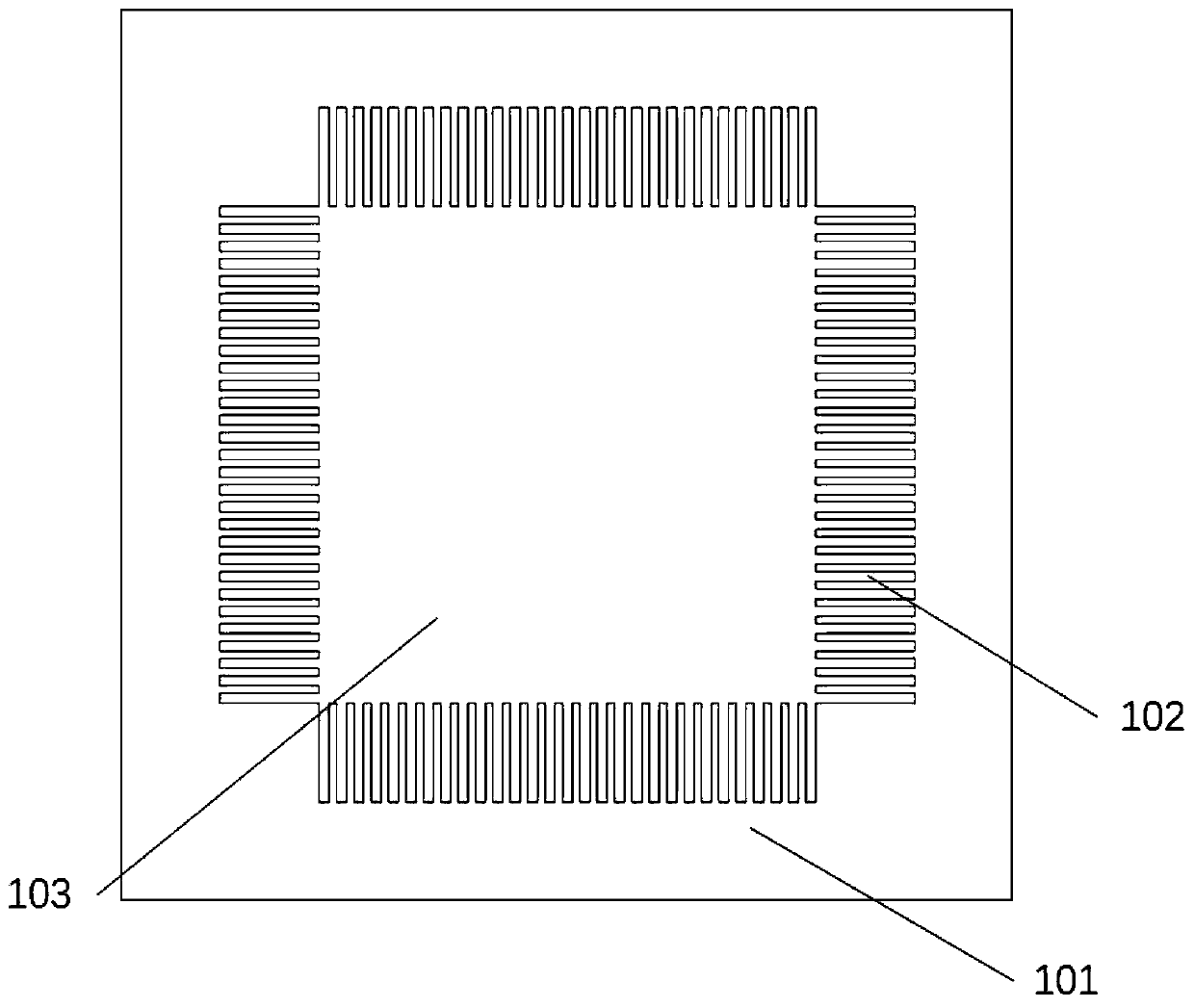

[0048]As shown in FIG. 1( a ), it is a top view of a tunable thin-film bulk acoustic resonator in Embodiment 1, and FIG. 1( b ) is a schematic diagram of a three-dimensional structure. On the first substrate 101 (not shown in FIG. 1( b ), a resonator 103 including a first interdigitated structure 102 and a first middle region, the first interdigitated structure 102 and the first middle region resonator 103 are both It consists of a first upper electrode 104 , a first piezoelectric material 105 and a first lower electrode 106 . The resonator in the middle region of Embodiment 1 is a quadrilateral structure, and its four sides have corresponding interdigitated structures, and the interdigitated structures corresponding to each side have the same shape, the same number, and the same width, length, and spacing. The fingers corresponding to each side are perpendicular to the corresponding side of the resonator in the middle area. The ends of the finger structures are all straight l...

Embodiment 2

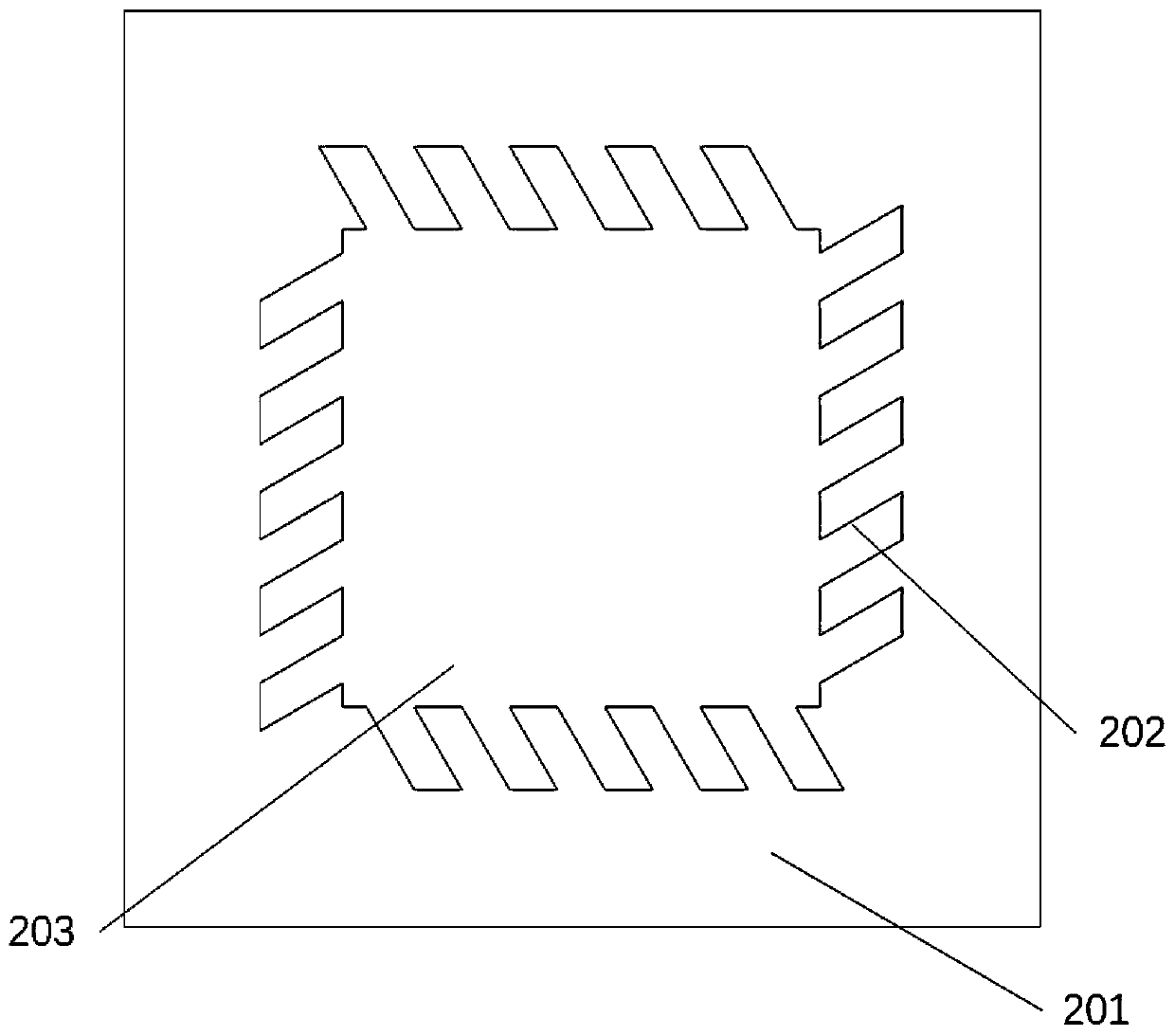

[0050] Fig. 2(a) is a top view of a tunable thin-film bulk acoustic resonator in Embodiment 2, and Fig. 2(b) is a schematic diagram of a three-dimensional structure. On the second substrate 201 (not shown in FIG. 2( b ), a resonator 203 including a second interdigitated structure 202 and a second middle region, the second interdigitated structure 202 and the second middle region resonator 203 are both It is composed of a second upper electrode 204 , a second piezoelectric material 205 and a second lower electrode 206 . The resonator in the middle area of Embodiment 2 is a quadrilateral structure, and its four sides have corresponding interdigitated structures, and the interdigitated structures corresponding to each side have the same shape, the same number, and the same width, length, and spacing. The interdigitated structures corresponding to each side are not perpendicular to the corresponding side of the resonator in the middle region, but form a certain angle with the co...

Embodiment 3

[0052] FIG. 3( a ) is a top view of a tunable thin-film bulk acoustic resonator in Embodiment 3, and FIG. 3( b ) is a schematic diagram of a three-dimensional structure. On the third substrate 301 (not shown in FIG. 3( b ), a resonator 303 including a third interdigitated structure 302 and a third middle region, the third interdigitated structure 302 and the third middle region resonator 303 are both It is composed of a third upper electrode 304 , a third piezoelectric material 305 and a third lower electrode 306 . In Embodiment 3, the resonator in the middle area is a quadrilateral structure, and its four sides have corresponding interdigitated structures, and the interdigitated structures corresponding to each side have the same shape, the same number, and the same width, length, and spacing. The interdigital structure corresponding to each side is perpendicular to the corresponding side of the resonator in the middle region, the ends of the interdigital structure are arcs, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com