Rear derailleur

A technology of rear derailleur and base, which is applied in chain/belt transmission, vehicle gearbox, transportation and packaging, etc. It can solve the problems of easy swing of the derailleur swing arm, easy detachment of the chain, and jamming of the guide wheel. Achieve the effects of slowing down the swing frequency and amplitude, solving the danger of chain off, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

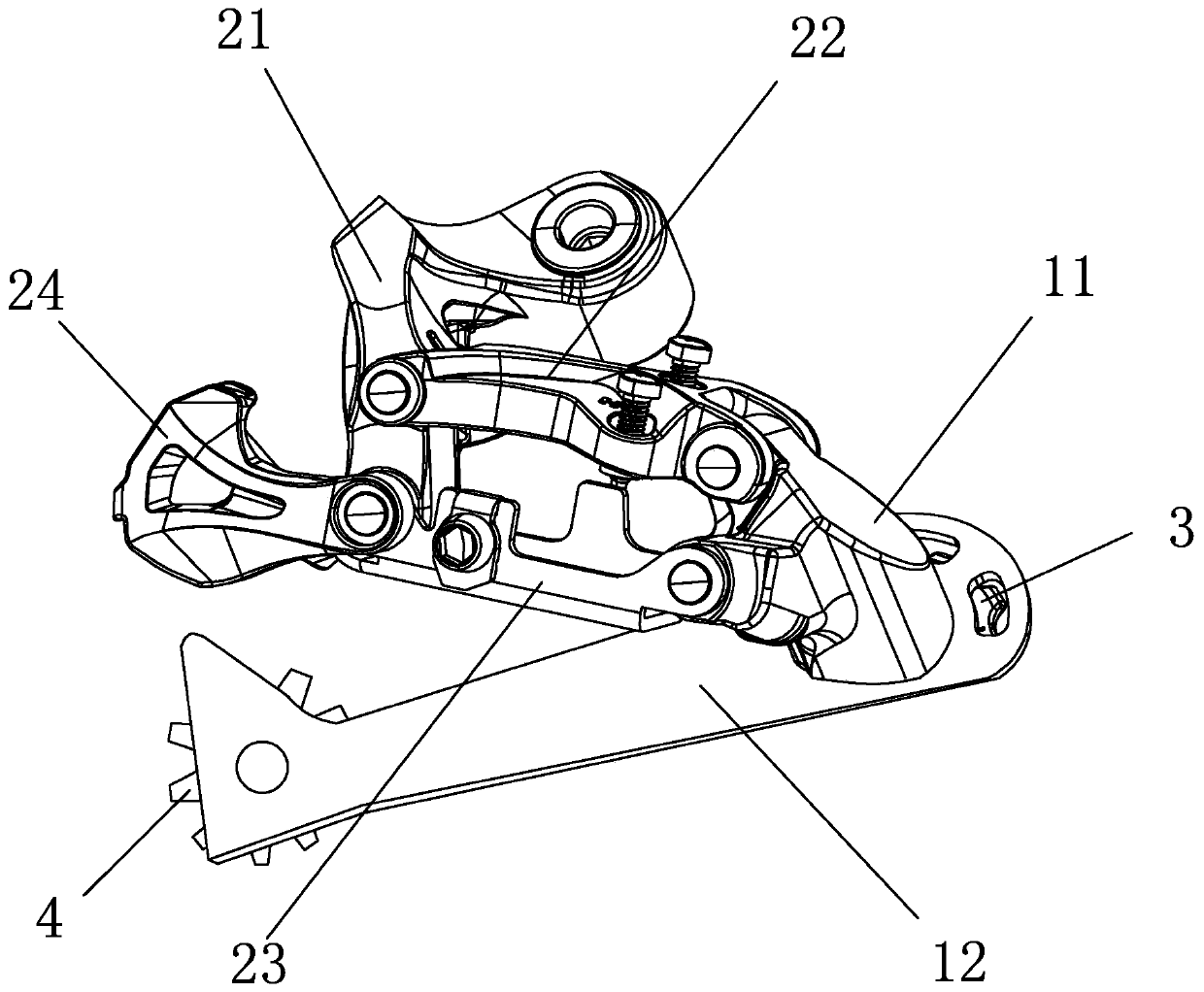

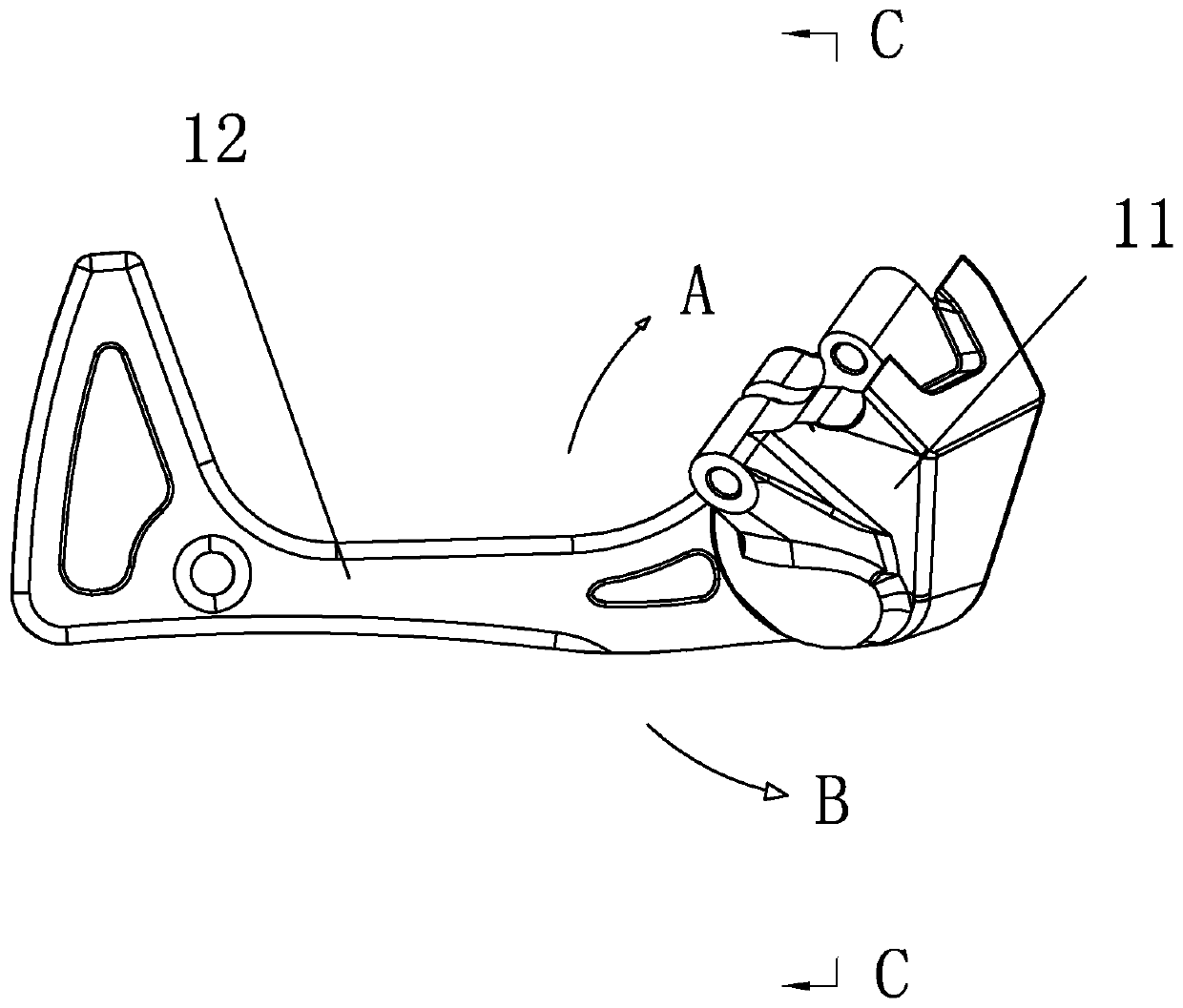

[0048] together with reference Figure 1 to Figure 9 , is a preferred embodiment, a rear derailleur with a one-way damping mechanism, installed at the rear of the bicycle, used to realize the tensioning and shifting process of the chain, including the derailleur assembly and the hinged derailleur The tensioning chain assembly on the chain assembly, the shifting chain assembly is connected to the shift line and toggles the chain tensioning assembly, and the chain tensioning assembly is used to install the chain and toggle the chain on different sprockets.

[0049]The tensioning chain assembly includes a base 11 and a swing arm 12, the swing arm 12 is rotatably connected to the base 11, the base 11 is hinged on the shifting chain assembly, and the rotation connection between the base 11 and the swing arm 12 is provided with a guide wheel 3, The guide wheel 3 is rotatably connected to the base 11, the swing arm 12 is provided with a tension pulley 4, the tension pulley 4 is insta...

Embodiment 2

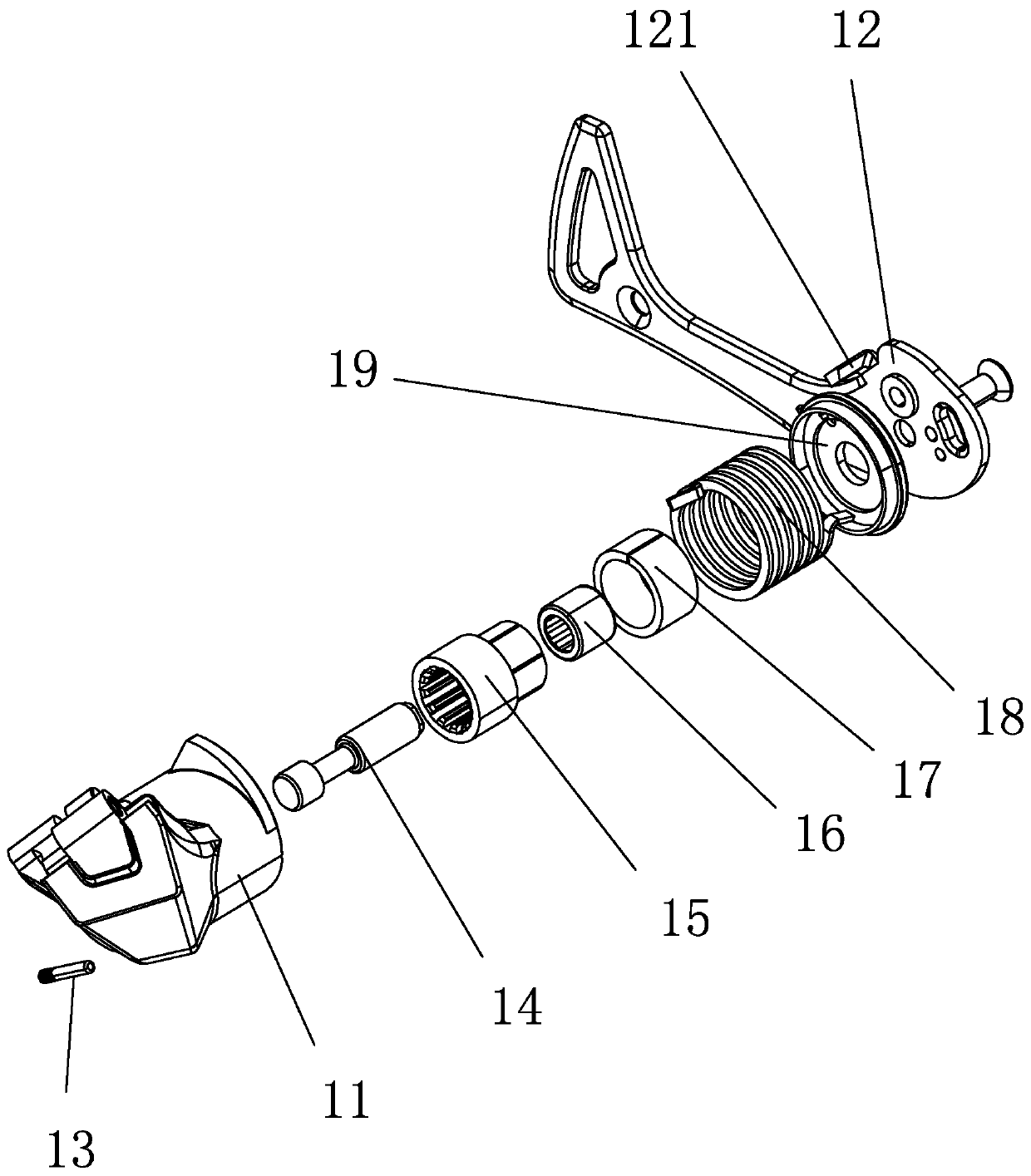

[0062] together with reference Figure 10 to Figure 13 , is another preferred embodiment of the present invention. In this embodiment, the one-way damping mechanism is also composed of a one-way bearing 16, a damping sleeve 15 and an elastic hoop 17. The elastic hoop 17 is set by four mutually close The elastic steel ring 172 on the damping sleeve 15 is formed. The damping sleeve 15 is provided with a limiting protrusion 156 for limiting the elastic steel ring 172. The front end of the rotating shaft 14 is fixedly connected to the limiting plate 26 by screws, and the limiting plate 26 is connected to the base. The internal structure of the seat 11 cooperates to limit the lateral position of the damping sleeve 15 and the one-way bearing 16 , so that the damping sleeve 15 and the one-way bearing 16 are installed on the rotating shaft 14 .

[0063] The elastic steel ring 172 is provided with a fracture opening 173, and the elastic steel ring 172 is made of steel, has a certain re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com