Shock insulation structure suitable for abutment rigid frame bridge and construction method

A technology for rigid-frame bridges and abutments, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of reducing the service life of bridges, worsening driving conditions, and early damage, reducing damage, and improving seismic resistance and deformation capacity. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

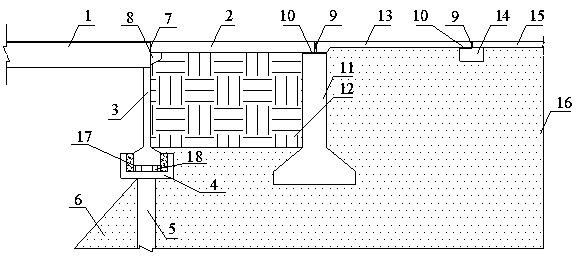

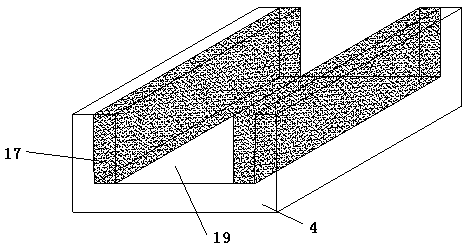

[0019] like Figure 1-2 As shown, a seismic isolation structure suitable for abutment rigid frame bridges includes thin-walled flexible main abutments and secondary abutments arranged at intervals, the secondary abutments are installed on the ground, and the lower end of the thin-walled flexible main abutment is set Cap, the cap is set on the upper end of the pile foundation, and the cap is provided with a notch for accommodating the lower end of the thin-walled flexible main abutment, and the bottom of the notch is provided with a shock-isolation support for supporting the thin-walled flexible main abutment, and the notch A water-resistant layer is set between the side walls of the mouth and the outer periphery of the lower end of the thin-walled flexible main abutment; the upper part of the encircled area of the thin-walled flexible main T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com