Test engine for testing solid rocket propellant

A solid rocket and propellant technology, which is applied to rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems that affect test accuracy, large propellant dose, and unstable burning surface, and achieve convenient operation and constant burning surface , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

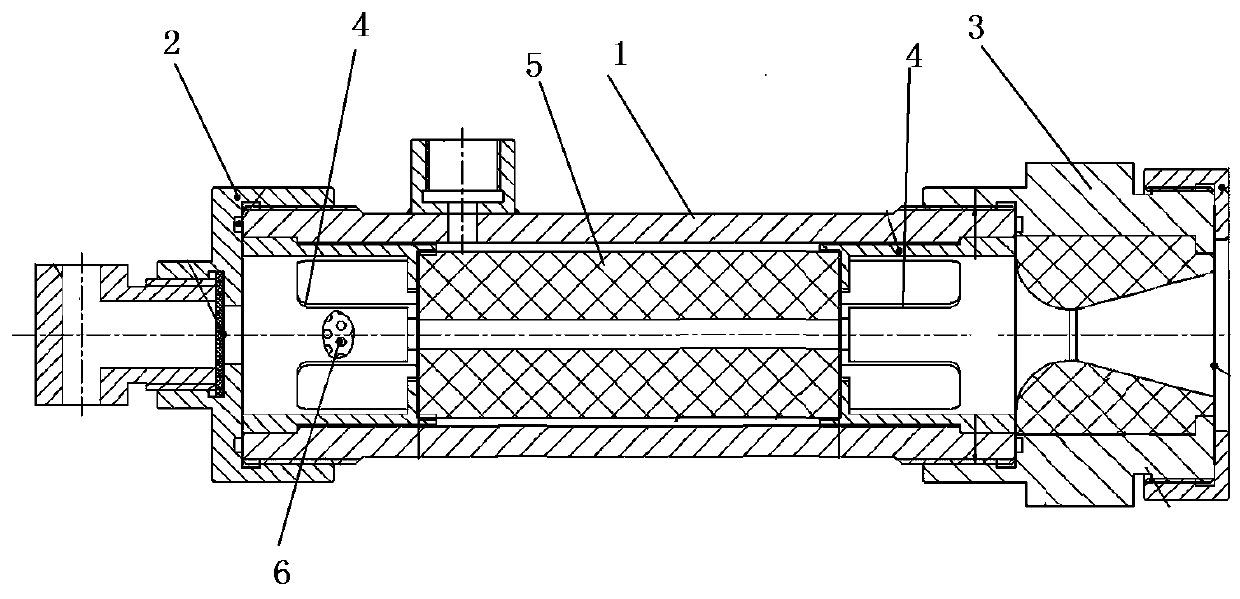

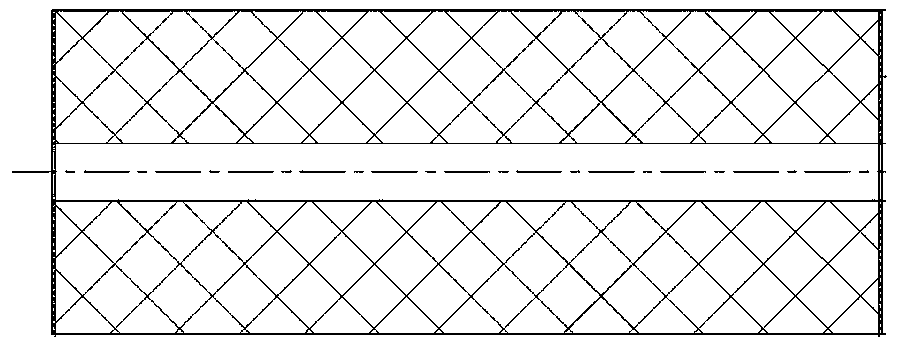

[0028] Such as Figure 1-3 As shown, a test engine for testing solid rocket propellants includes a combustion chamber casing 1, one end of which is provided with a top cover 2, and the other end is connected with a nozzle assembly 3; The two ends of the inside of the chamber are provided with hollow-out grain support 4, and the two grain supports are arranged opposite to each other, with a propellant grain 5 installed between them, and an ignition powder pack 6 is arranged in the grain support 4 at one end of the top cover; The propellant grain is cylindrical, and the central axis is provided with an inner hole; the end face of the propellant grain is in contact with the grain bracket and is clamped tightly, and there is a gap between the outer wall of the propellant grain and the inner wall of the combustion chamber shell.

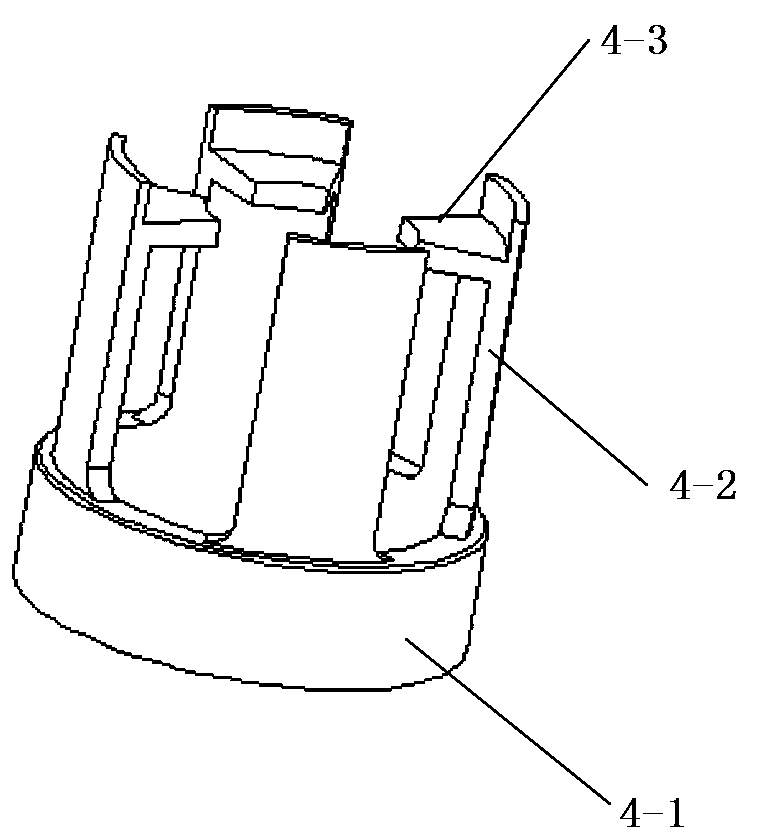

[0029] The drug column support includes a base 4-1, which is annular, and a plurality of arc-shaped support pieces 4-2 are installed on one end of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com