Method for preparing iridium/iridium oxide pH electrode through supercritical treatment

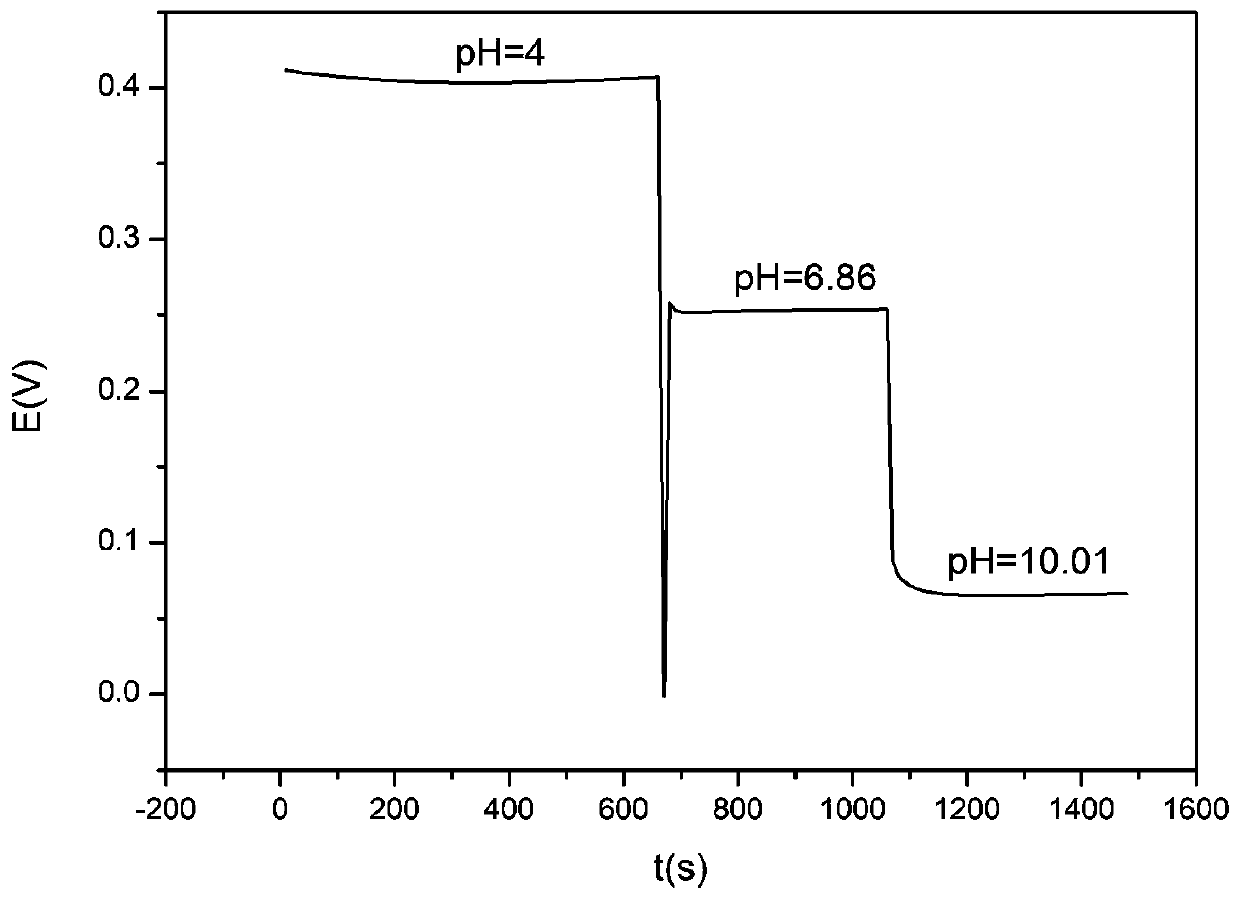

A supercritical, iridium oxide technology, applied in the direction of material electrochemical variables, material analysis by electromagnetic means, instruments, etc., can solve problems such as insufficient hydration degree, electrode potential drift, limited application, etc., to achieve reproducibility and Enhanced sensitivity, stable electrode performance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

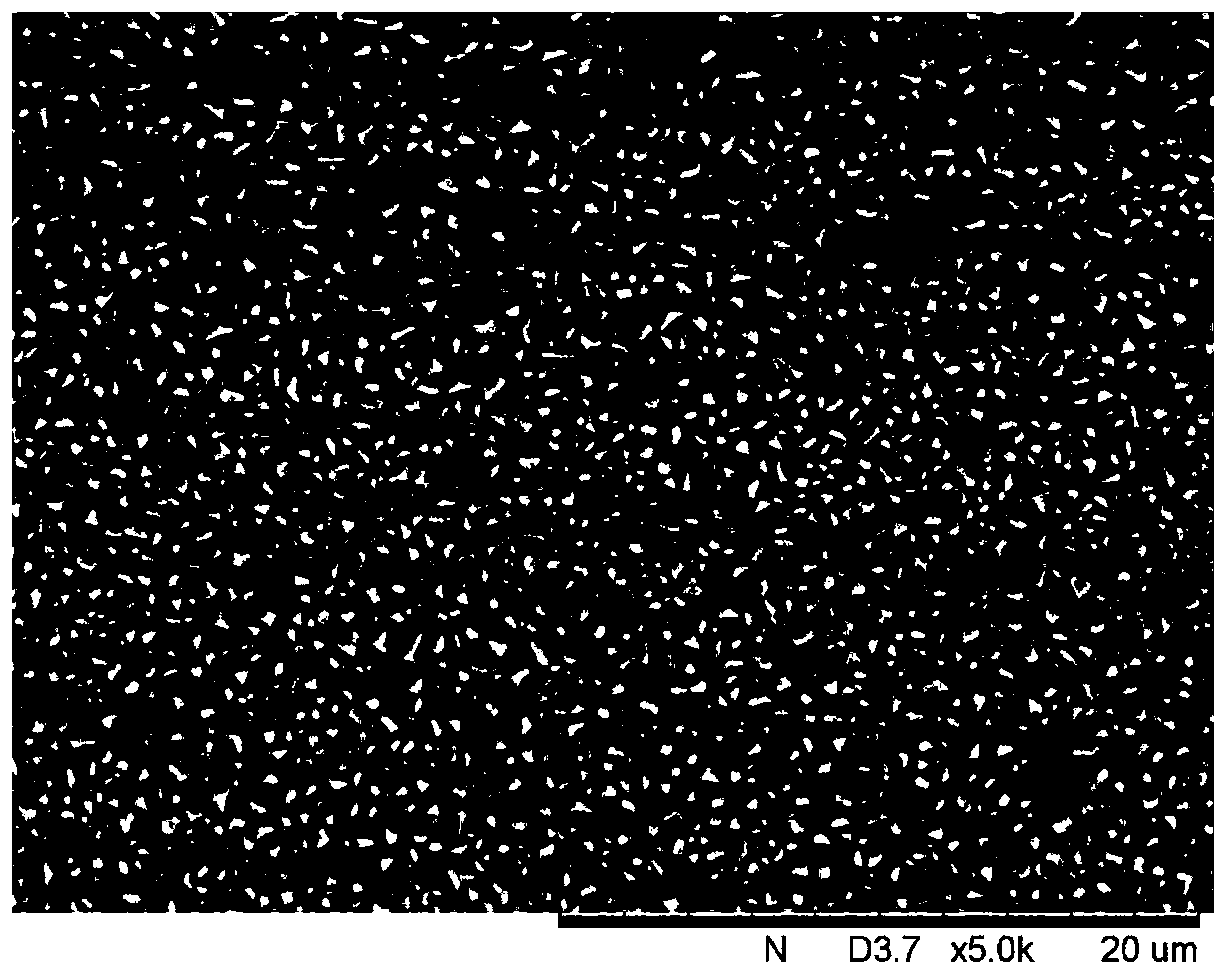

[0016] Step 1: Polish a section of 2cm long iridium wire with sandpaper, and ultrasonically clean it in 2M hydrochloric acid solution, acetone and ultrapure water respectively; then, immerse the iridium wire in potassium nitrate and In the powder of sodium nitrate, the temperature was programmed to rise to 800°C at 5°C / min in a tube furnace, and the temperature was kept constant for 45 minutes;

[0017] Step 2: Put the iridium / iridium oxide pH electrode prepared in step 1 into a supercritical device, and treat it in a supercritical environment at 300°C and 30Mpa for 5 hours. Scrape off the oxide film with a length of about 1 mm at one end of the obtained electrode to obtain an iridium / iridium oxide pH electrode.

Embodiment 2

[0019] Step 1: A section of 3cm long iridium wire was polished bright with sandpaper, and ultrasonically cleaned in 4M hydrochloric acid solution, acetone and ultrapure water respectively; subsequently, the iridium wire was immersed in potassium nitrate and In the powder of sodium nitrate, the temperature was programmed to rise to 600°C at 3°C / min in a tube furnace, and the temperature was kept constant for 45min;

[0020] Step 2: Put the iridium / iridium oxide pH electrode prepared in step 1 into a supercritical device, and treat it in a supercritical environment at 300°C and 30Mpa for 5 hours. The oxide film with a length of about 2 mm was scraped off one end of the obtained electrode to obtain an iridium / iridium oxide pH electrode.

Embodiment 3

[0022] Step 1: A section of 4cm long iridium wire is polished bright with sandpaper, and ultrasonically cleaned in 3M hydrochloric acid solution, acetone and ultrapure water respectively; subsequently, the iridium wire is placed in potassium nitrate and Cover with sodium nitrate powder; program the temperature to 800°C at 5°C / min in a tube furnace, and keep the temperature constant for 45min;

[0023] Step 2: Put the iridium / iridium oxide pH electrode prepared in step 1 into a supercritical device, and treat it in a supercritical environment at 400°C and 40Mpa for 3 hours. The oxide film with a length of about 2 mm was scraped off one end of the obtained electrode to obtain an iridium / iridium oxide pH electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com