A kind of improved method of iridium/iridium oxide pH electrode stability

An iridium oxide and stability technology, applied in the field of improvement of iridium/iridium oxide pH electrode stability, can solve the problems of insufficient hydration, electrode potential drift, long hydration period, etc., to achieve enhanced reproducibility and sensitivity , The effect of stable electrode performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

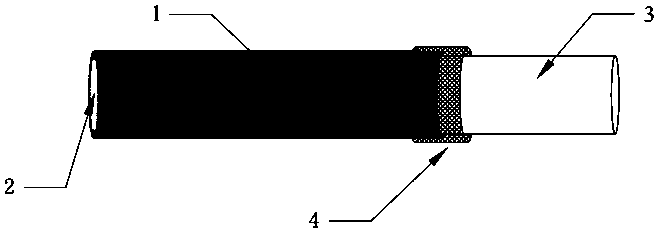

[0016] (1) Polish a section of iridium wire with a length of about 2 cm to a bright finish with sandpaper, and then ultrasonically clean it in 3M HCl, acetone, and ultrapure water for 30 minutes each. Then the iridium wire was immersed in 5M NaOH solution and boiled for 1 h. In the muffle furnace, the temperature was programmed to rise to 800 °C at 5 °C / min, and the temperature was kept constant for 30 min. Repeat the dip-oxidation process 2 times. Scrape one end of the oxide film with a length of about 1∼2mm, and weld the platinum wire to draw out the ohmic potential, and coat the insulating resin on the welded part to obtain an iridium / iridium oxide pH electrode; its structure is as follows: figure 1 As shown in the figure, iridium oxide, 1; metallic iridium substrate 2; platinum wire 3; insulating coating 4;

[0017] (2) Put the iridium / iridium oxide pH electrode prepared in (1) in the polytetrafluoroethylene lining, add ultrapure water to it, keep the filling degree of t...

Embodiment 2

[0019] (1) Polish a section of iridium wire with a length of about 2 cm to a bright finish with sandpaper, and then ultrasonically clean it in 3M HCl, acetone, and ultrapure water for 30 minutes each. Then the iridium wire was immersed in 5M NaOH solution and boiled for 1 h. In the muffle furnace, the temperature was programmed to rise to 800 °C at 5 °C / min, and the temperature was kept constant for 30 min. Repeat the dip-oxidation process 2 times. Scrape one end of the oxide film with a length of about 1∼2mm, and weld the platinum wire to lead out the ohmic potential, and coat the welding place with insulating resin to obtain an iridium / iridium oxide pH electrode;

[0020] (2) Put the iridium / iridium oxide pH electrode prepared in (1) in the polytetrafluoroethylene lining, add ultrapure water to it, keep the filling degree of the reactor at 50%, and put it at 100°C The electrode was heated in water for 24 hours; a treated iridium / iridium oxide pH electrode was obtained.

Embodiment 3

[0022] (1) Polish a section of iridium wire with a length of about 2 cm to a bright finish with sandpaper, and then ultrasonically clean it in 3M HCl, acetone, and ultrapure water for 30 minutes each. Then the iridium wire was immersed in 5M NaOH solution and boiled for 1 h. In the muffle furnace, the temperature was programmed to rise to 800 °C at 5 °C / min, and the temperature was kept constant for 30 min. Repeat the dip-oxidation process 2 times. Scrape one end of the oxide film with a length of about 1∼2mm, and weld the platinum wire to lead out the ohmic potential, and coat the welding place with insulating resin to obtain an iridium / iridium oxide pH electrode;

[0023] (2) Put the iridium / iridium oxide pH electrode prepared in (1) in the polytetrafluoroethylene lining, add ultrapure water to it, keep the filling degree of the reactor at 80%, and put The electrode was hydrothermally hydrated for 12 hours; a treated iridium / iridium oxide pH electrode was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com