Production workshop personnel positioning supervision method and system

A technology for production workshops and supervision systems, applied in closed-circuit television systems, time registers, instruments, etc., can solve problems such as potential safety hazards, multiple card swipes for one person to enter and exit, and inconvenient management of workshop personnel to achieve simple structure and precise production workshops The effect of the people management model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

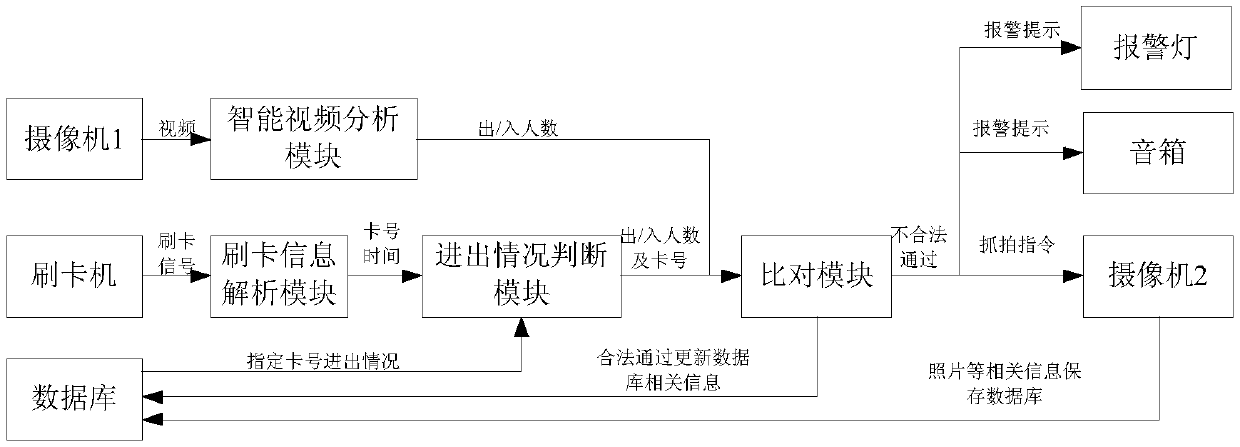

[0015] The present invention effectively solves the problem of personnel access control through the method of combining intelligent video analysis and traditional card swiping.

[0016] (1) First of all, a camera needs to be installed on the ceiling directly above the entrance and exit of the production workshop to obtain real-time surveillance video. Through the intelligent analysis algorithm of the video, it can determine the direction of people passing and how many people have passed in total. The intelligent analysis algorithm can carry out self-adaptive and continuous learning through the neural network, and correct the personnel judgment factor to achieve the purpose of accurately determining the number of people.

[0017] (2) At the same time, a credit card machine is installed at the entrance and exit, and the personnel need to swipe the card first when passing through. If the card is swiped within the specified time, no matter how many times it is considered as a vali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com