Semiconductor laser and preparation method thereof

A semiconductor and laser technology, applied in semiconductor lasers, semiconductor laser devices, lasers, etc., can solve the problems of low saturated output power, low yield, and inability to achieve high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

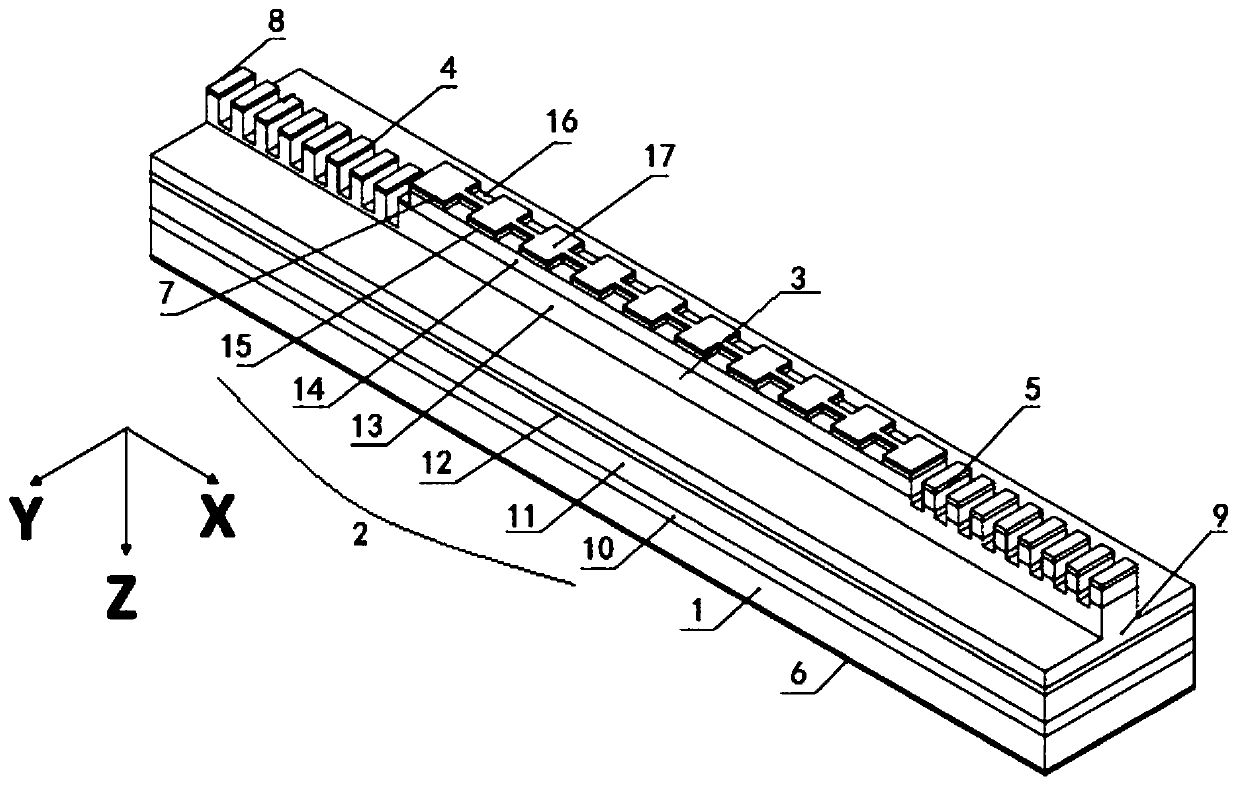

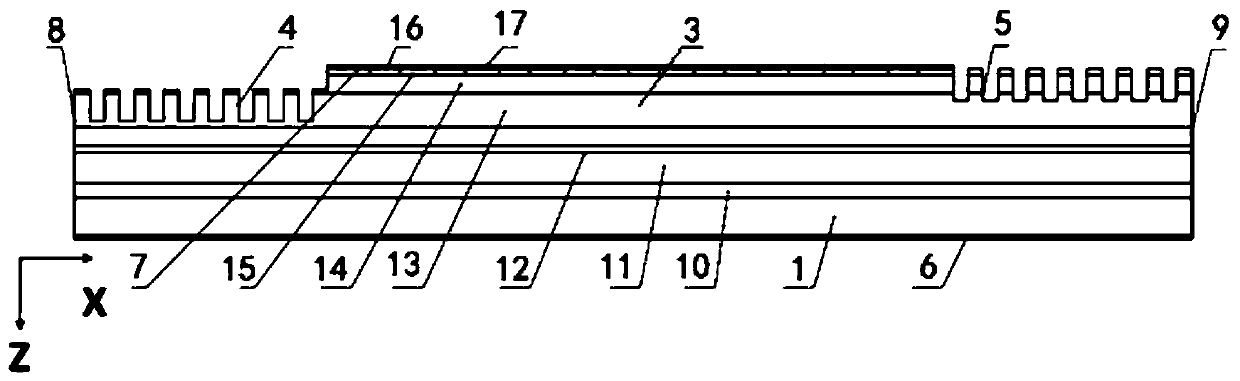

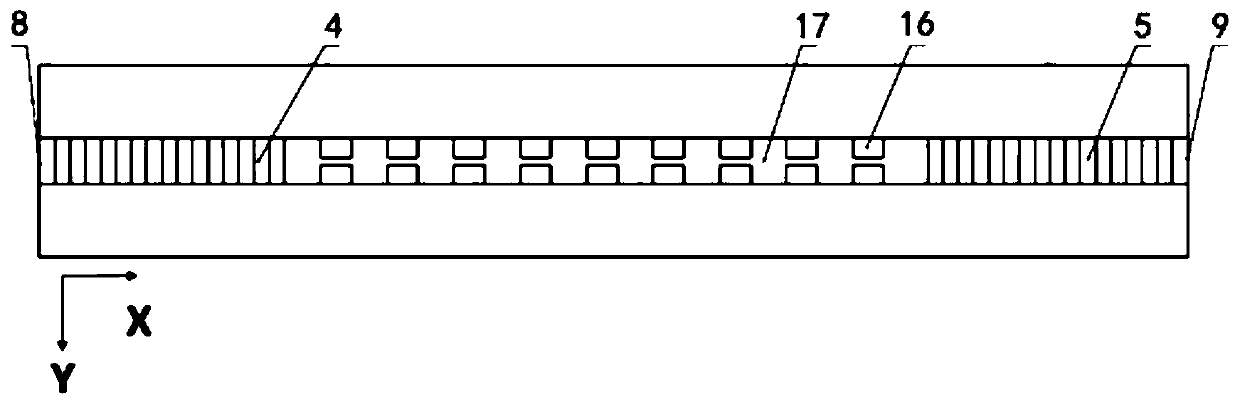

[0046]The core of the present invention is to provide a semiconductor laser. In the prior art, narrow linewidth semiconductor lasers usually include distributed feedback (DFB) lasers and ridge DBR lasers, although great progress has been made in increasing output power and reducing spectral linewidth. However, the preparation of the grating structure of the distributed feedback semiconductor laser (DFB) generally requires technologies such as secondary epitaxy or electron beam lithography, resulting in high chip manufacturing costs and low yields; ridge DBR lasers generally use ridges (width 2- 5 micron) waveguide structure suppresses high-order side modes and reduces the laser linewidth, which leads to low saturated output power and cannot achieve high-power narrow-linewidth lasers.

[0047] In the semiconductor laser provided by the present invention, a narrow strip waveguide is etched on the surface of the transmission layer facing away from the substrate, a first Bragg gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com