Combined dovetail guide expanding cone

A dovetail-guided and combined technology, applied in the field of expanding cones, can solve the problems of long production cycle, low maintenance feasibility, production stagnation and other problems of integral structure cones, so as to improve yield and maintainability, and reduce downtime cost, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

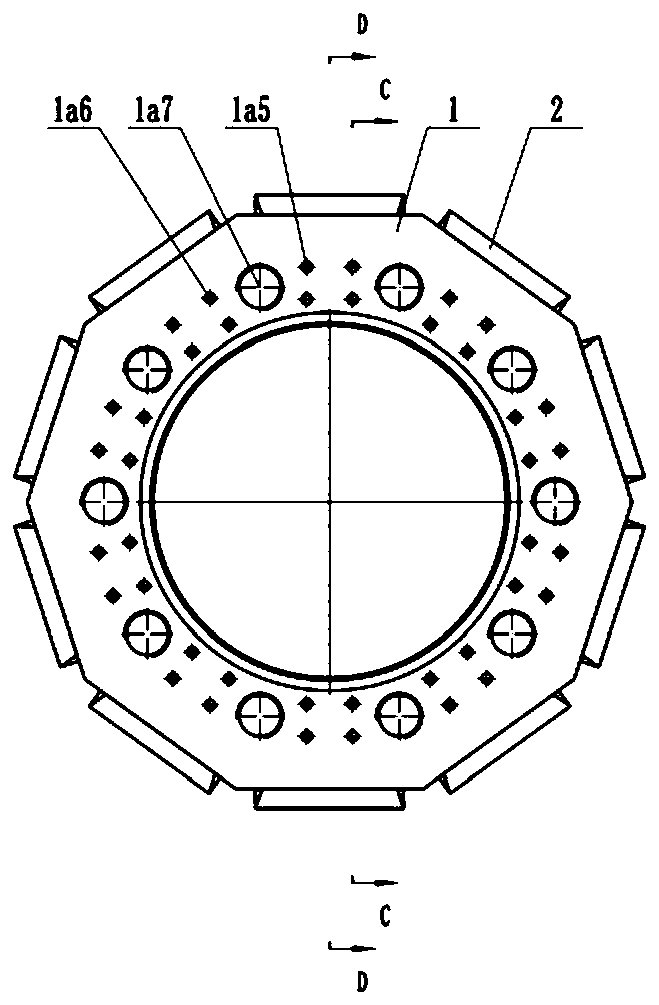

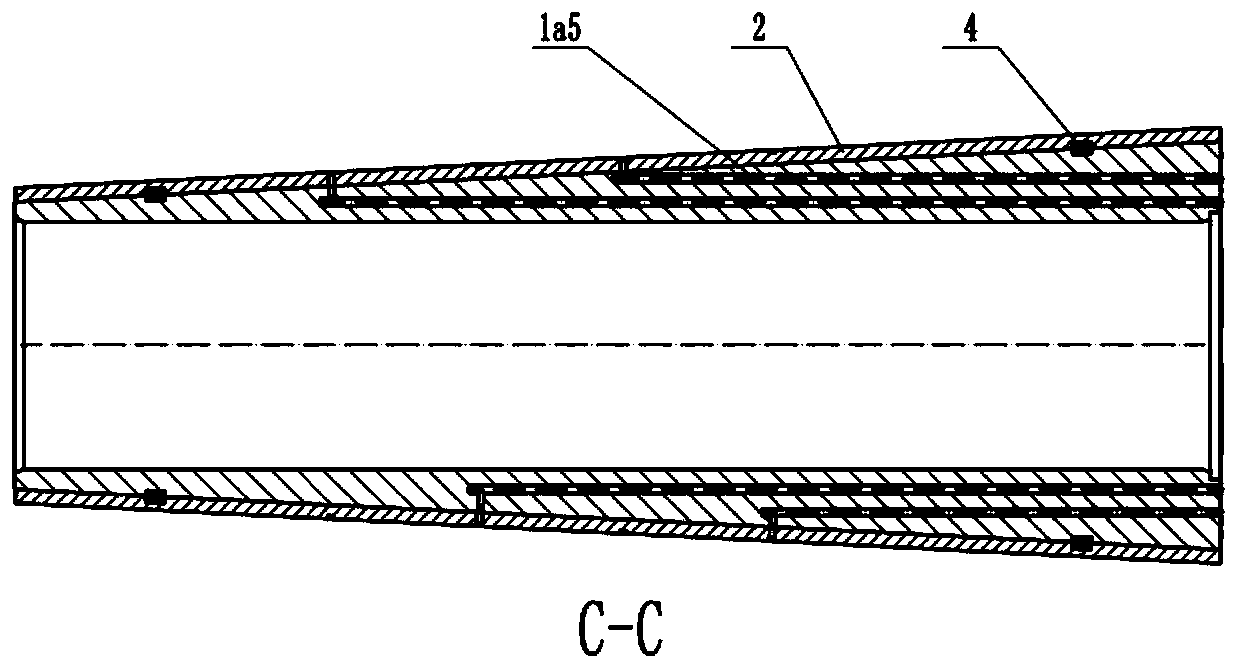

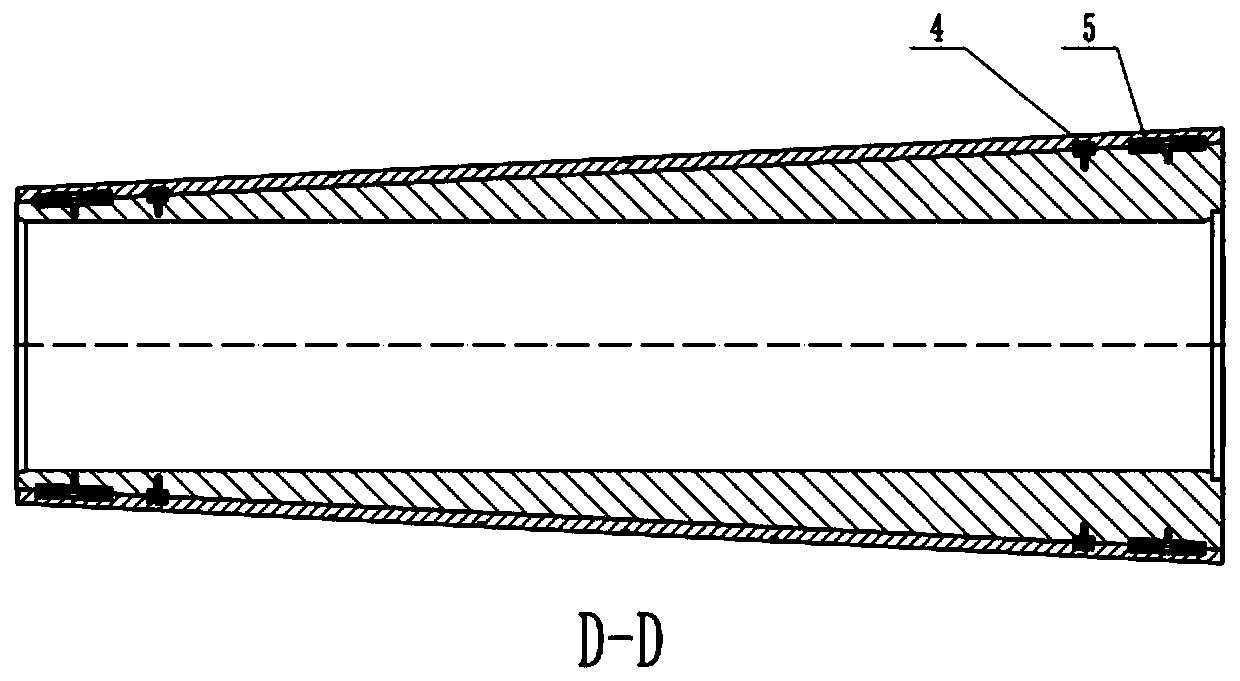

[0024] like Figure 1-Figure 7 As shown, the present invention includes a plurality of dovetail guide slides 2 of a cone parent body 1; the pyramid parent body 1 adopts a regular octagonal truss, or a regular ten-prism truss, or a regular twelve-prism truss; the pyramidal body 1 adopts The number of sides of the bottom surface of the prism is an even number and not less than 8. The large end surface of the cone body 1 is provided with a connecting hole 1a7 connected with the lubricating sleeve and a plurality of groups of lubricating hole inlets 1a6. Each side of the cone body 1 is respectively provided with a horizontal limit pin hole 1a1, a longitudinal limit pin hole 1a2, a slide plate connection screw hole 1a3, and a lubricating hole outlet 1a4. The lubricating hole outlet 1a4 on each side corresponds to a group of lubricating holes. The hole inlet 1a6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com