Valve processing equipment

A technology for processing equipment and valves, which is applied in the direction of metal processing equipment, metal processing, drilling/drilling equipment, etc., can solve the problem of low drilling efficiency of the valve body 1, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

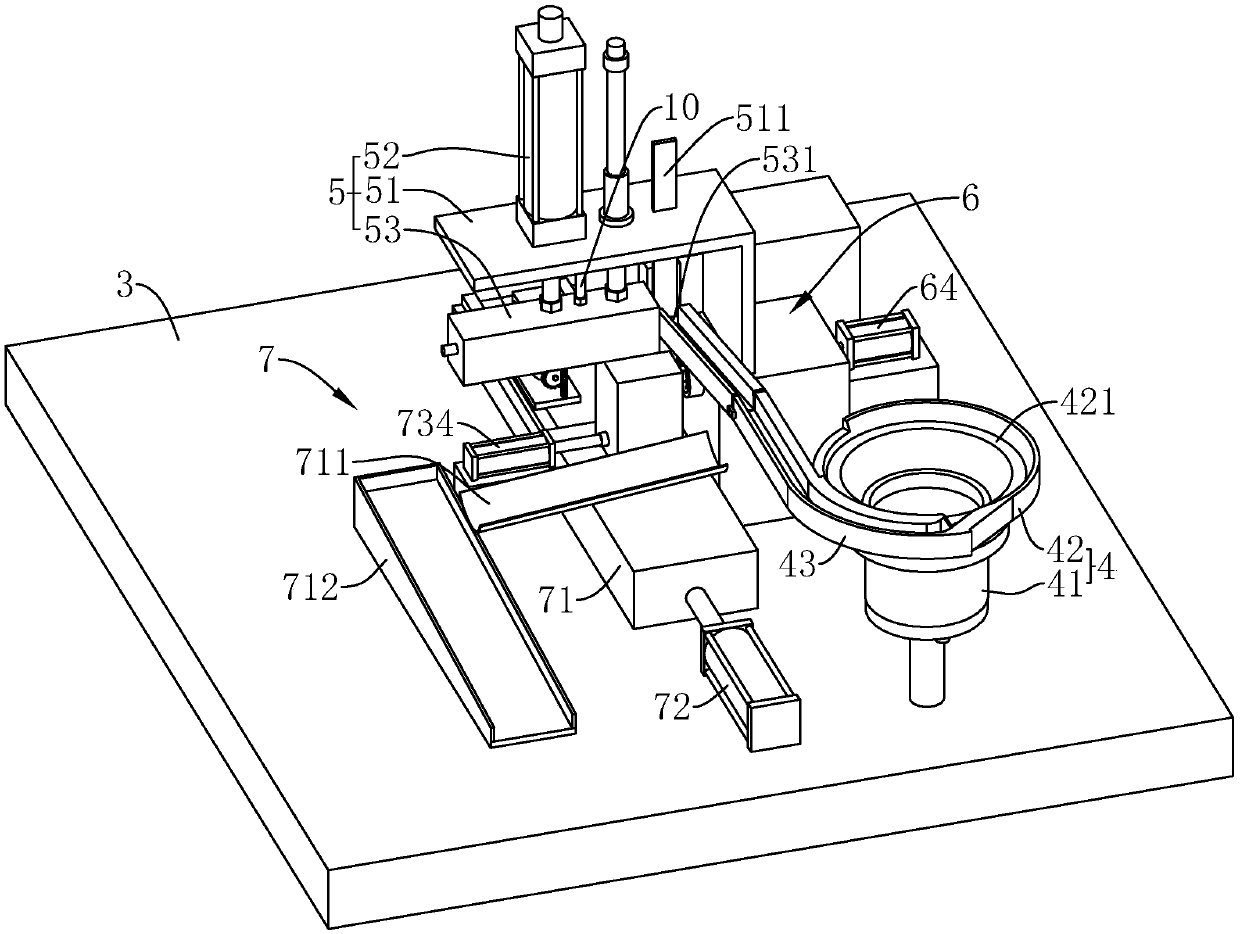

[0037]The present invention will be described in further detail below in conjunction with the accompanying drawings.

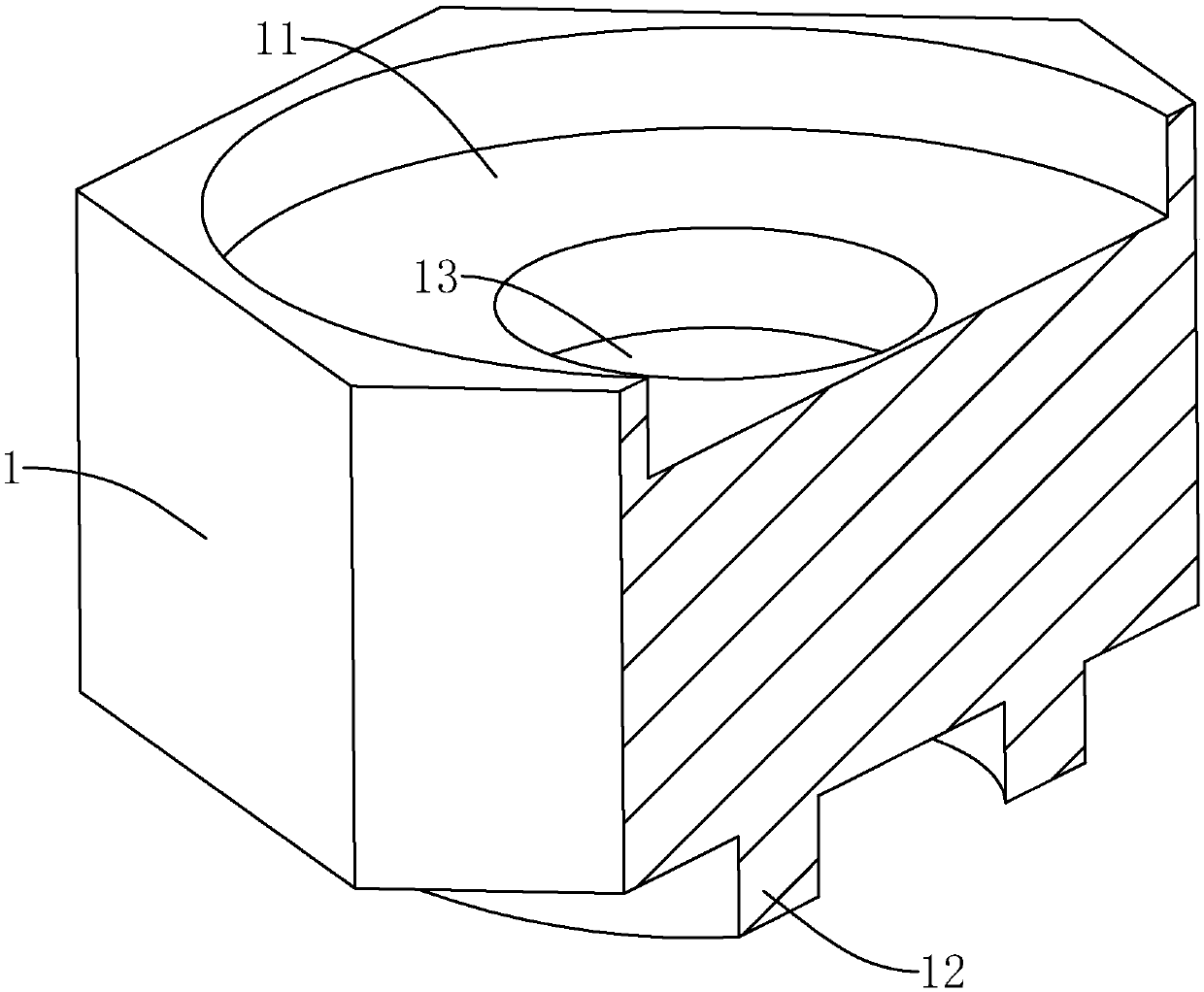

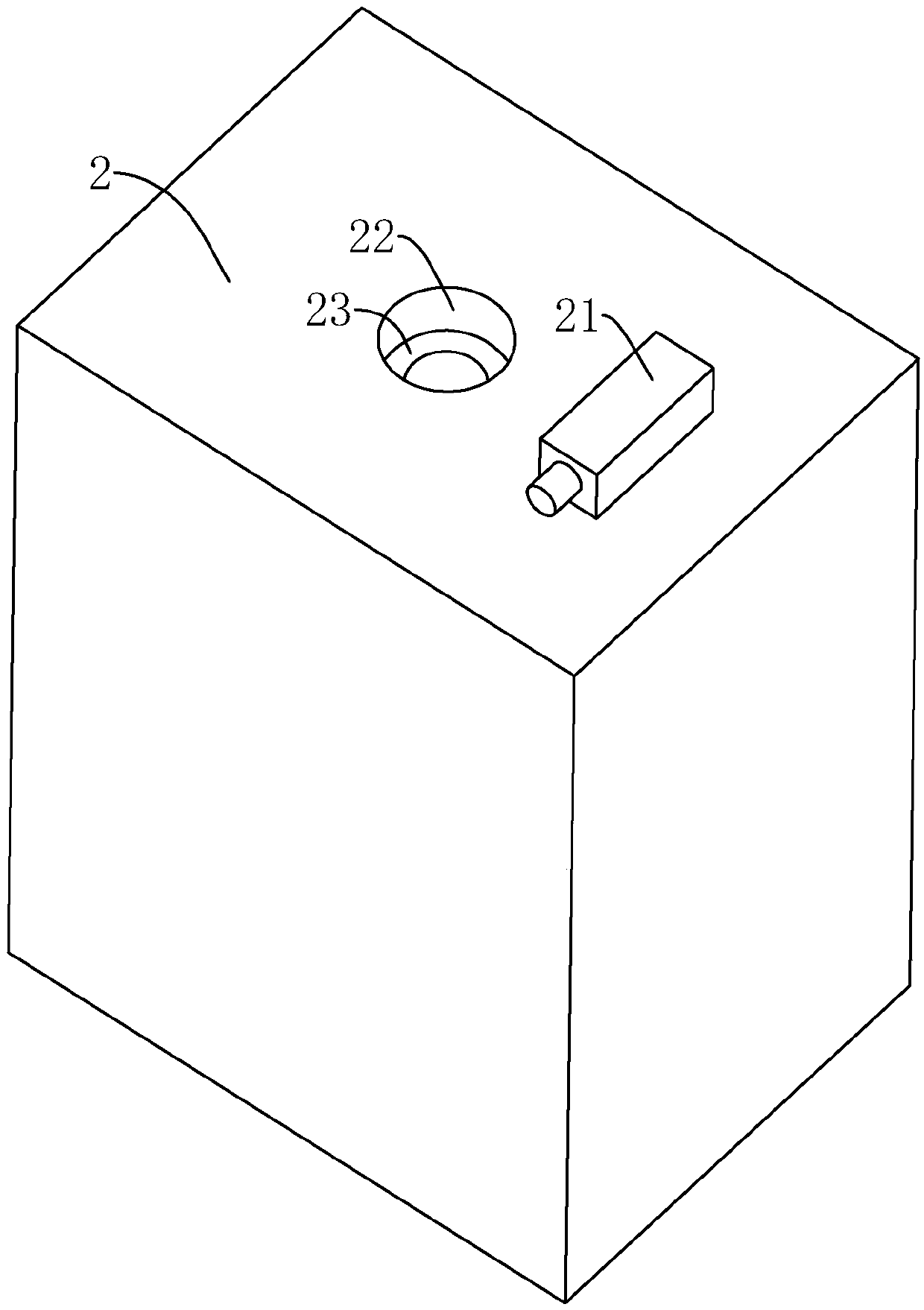

[0038] see image 3 , a valve processing equipment, comprising a frame 3, a feeding mechanism 4 arranged on the frame 3, a pushing mechanism 5 arranged on one side of the feeding mechanism 4, and a clamping mechanism 6 arranged below the pushing mechanism 5, a drill Hole mechanism7.

[0039] The feeding mechanism 4 includes a vibrating table 41 and a spiral vibrating disc 42 arranged in the vibrating table 41. The vibrating table 41 is used to drive the vibrating disc 42 to vibrate. Road 421, the outer wall of the vibrating plate 42 top is provided with a discharge part 43 connected with the feeding channel 421; the valve to be processed is placed on the vibrating plate 42, and the vibrating table 41 is opened to drive the vibrating plate 42 to vibrate so that the valve enters In the feeding channel 421 and gradually conveyed to the discharge part 43, the di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap