Antibacterial and deodorant insole and preparation method thereof

A technology for insoles and deodorization, applied in insoles, footwear, clothing, etc., can solve the problem of limited deodorization, and achieve the effect of improving the warm and humid environment, light texture and toughness, and inhibiting reproduction and growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] An antibacterial and deodorant insole comprises a cushion surface and a sole, and a filling layer is arranged between the cushion surface and the sole.

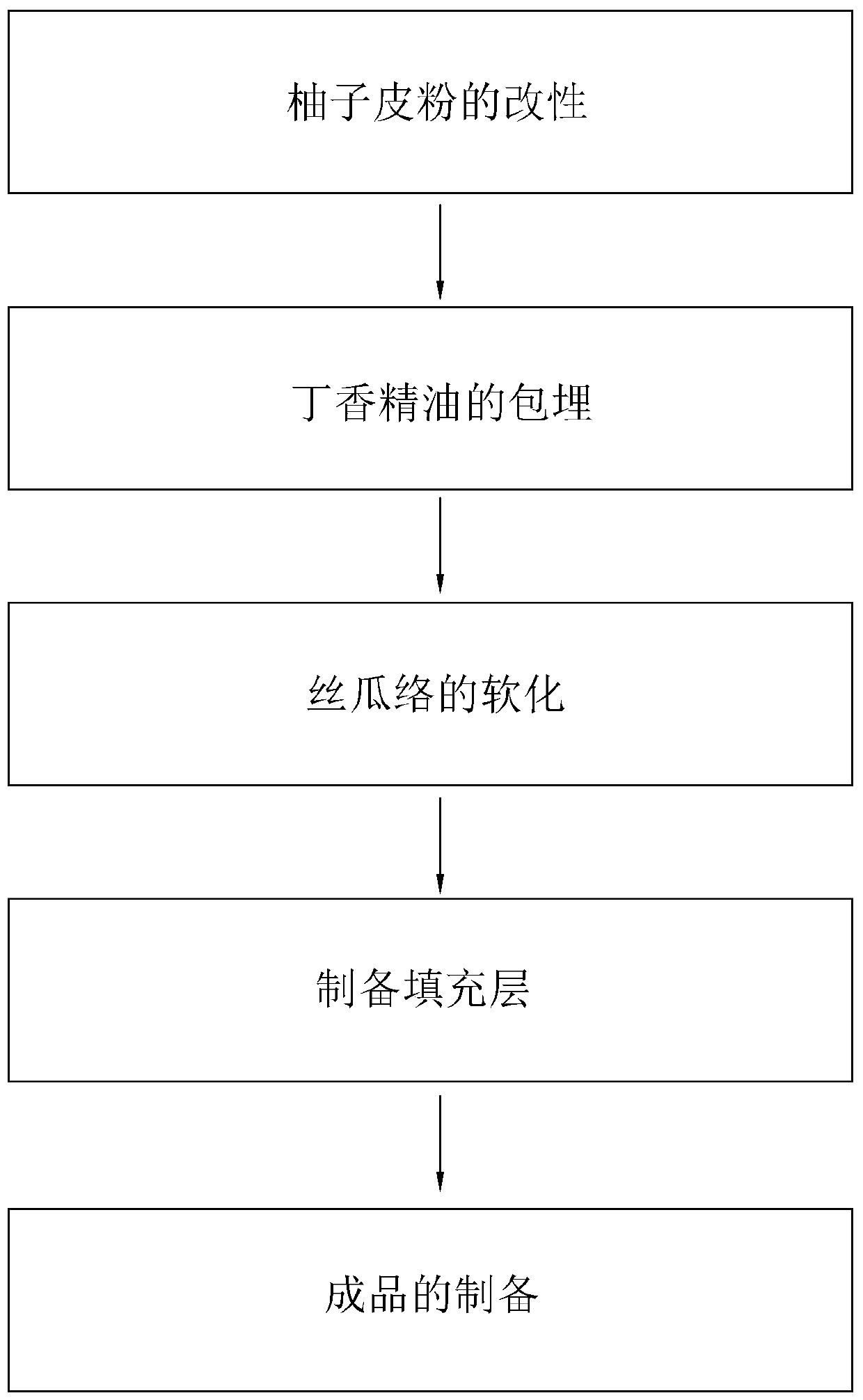

[0049] Such as figure 1 Shown, the preparation method of this insole may further comprise the steps:

[0050] S1. Modification of pomelo peel powder: take 10 parts by weight of dry pomelo peel powder and ferric chloride solution, mix and stir for 10-15 minutes, mix well, wash with water for 5-10 minutes, and put it in 50-55°C for drying ;

[0051] S2, Embedding of clove essential oil: Take an appropriate amount of β-cyclodextrin and add distilled water at a volume ratio of 1:6, stir to form a saturated solution of β-cyclodextrin, take 0.3 parts by weight of clove essential oil and mix it at a volume ratio of 1:20 Add ethanol solution to dissolve, add dropwise to β-cyclodextrin saturated solution, stir at 60-65°C for 2.5-3h, after the solution is cooled to room temperature, put it at 2-6°C for 24h, Suction filtration...

Embodiment 2

[0057] The difference with Example 1 is that the preparation method of the insole comprises the following steps:

[0058] S1. Modification of pomelo peel powder: take 15 parts by weight of dried pomelo peel powder and ferric chloride solution, mix and stir for 10-15 minutes, mix well, wash with water for 5-10 minutes, and dry at 50-55°C ;

[0059] S2, Embedding of clove essential oil: Take an appropriate amount of β-cyclodextrin and add distilled water at a volume ratio of 1:6, stir to form a saturated solution of β-cyclodextrin, take 0.5 parts by weight of clove essential oil and add it at a volume ratio of 1:20 Add ethanol solution to dissolve, add dropwise to β-cyclodextrin saturated solution, stir at 60-65°C for 2.5-3h, after the solution is cooled to room temperature, put it at 2-6°C for 24h, Suction filtration and washing, drying the pomelo peel powder in S1 at 50-55°C at the same time, and drying to constant weight to obtain the microcapsule product;

[0060] S3, soft...

Embodiment 3

[0064] The difference with Example 1 is that the preparation method of the insole comprises the following steps:

[0065] S1. Modification of pomelo peel powder: take 12 parts by weight of dried pomelo peel powder and ferric chloride solution, mix and stir for 10-15 minutes, mix well, wash with water for 5-10 minutes, and dry at 50-55°C ;

[0066] S2, Embedding of clove essential oil: Take an appropriate amount of β-cyclodextrin and add distilled water at a volume ratio of 1:6, stir to form a saturated solution of β-cyclodextrin, take 0.4 parts by weight of clove essential oil and mix it at a volume ratio of 1:20 Add ethanol solution to dissolve, add dropwise to β-cyclodextrin saturated solution, stir at 60-65°C for 2.5-3h, after the solution is cooled to room temperature, put it at 2-6°C for 24h, Suction filtration and washing, drying the pomelo peel powder in S1 at 50-55°C at the same time, and drying to constant weight to obtain the microcapsule product;

[0067] S3, soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com