Perishable garbage pretreatment device and perishable garbage pretreatment method

A pretreatment device and technology for garbage, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve problems such as occupying a large amount of land and composting cannot be reduced, and achieve strong adaptability and system operation. Smooth, Difficulty-Reducing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

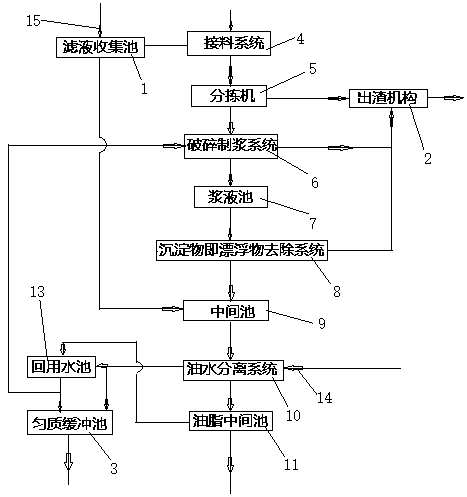

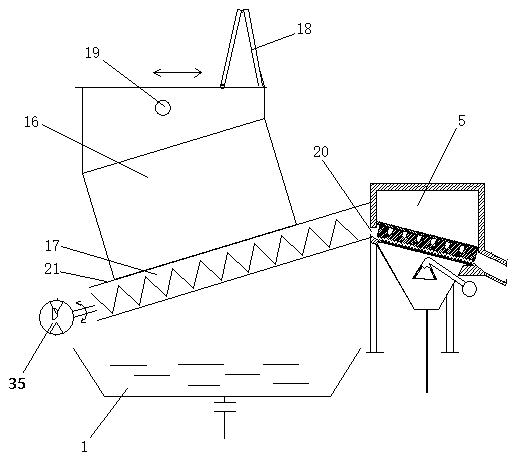

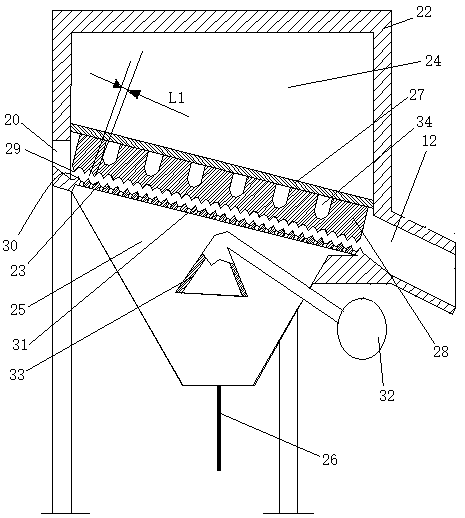

[0035] see figure 1, a perishable garbage pretreatment device, including a filtrate collection tank 1, a slag discharge mechanism 2, a homogeneous buffer tank 3, and a material receiving system 4, a sorting machine 5, a crushing and pulping system 6, and a slurry tank that are sequentially connected together 7. Sediment and floating matter removal system 8, intermediate tank 9, oil-water separation system 10 and grease intermediate tank 11. The inlet end of the homogeneous buffer tank is connected with the outlet of the water phase material of the oil-water separation system. The inlet end of the grease intermediate tank is connected with the outlet of the oil phase substance of the oil-water separation system. The filtrate collection tank is used to receive the liquid flowing out of the material receiving system. The output end of the filtrate collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com