Cycloidal gear grinding tool

A cycloidal wheel and tooling technology, which is applied to gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve problems such as radial runout, difficulty in ensuring shape and position, inability to guarantee processing quality, and complicated production processes, etc., to improve processing Quality, avoiding the difficulty of aligning teeth, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

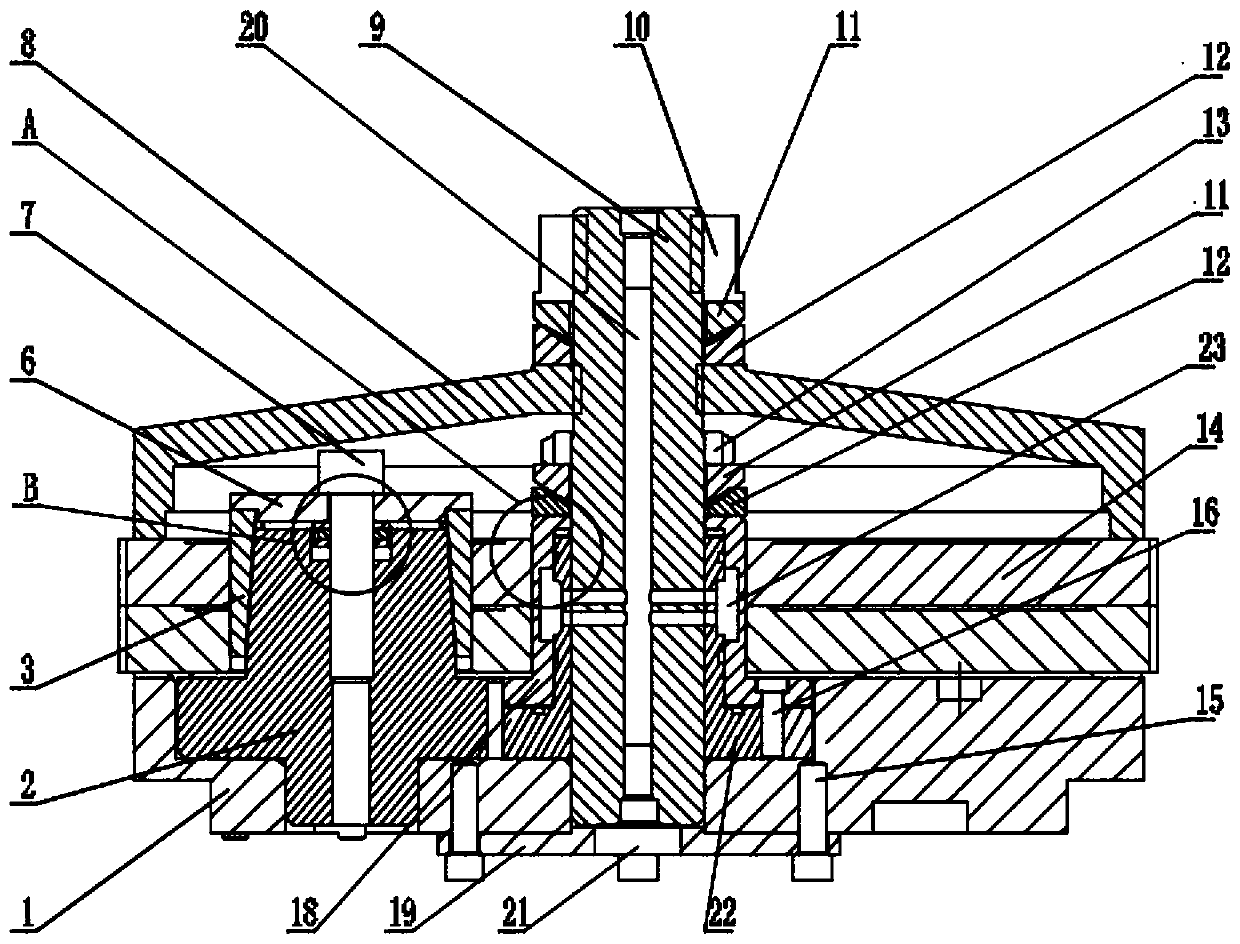

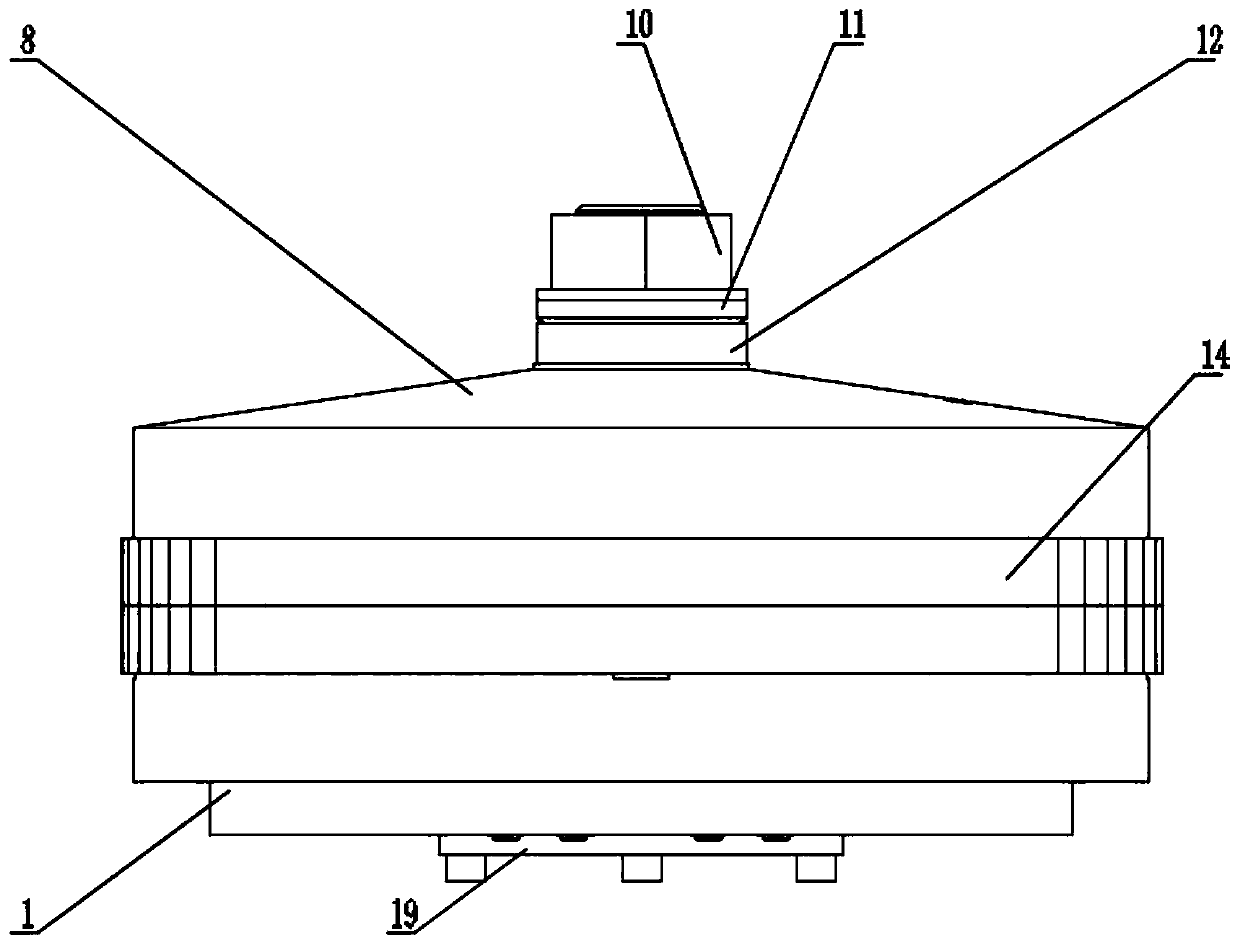

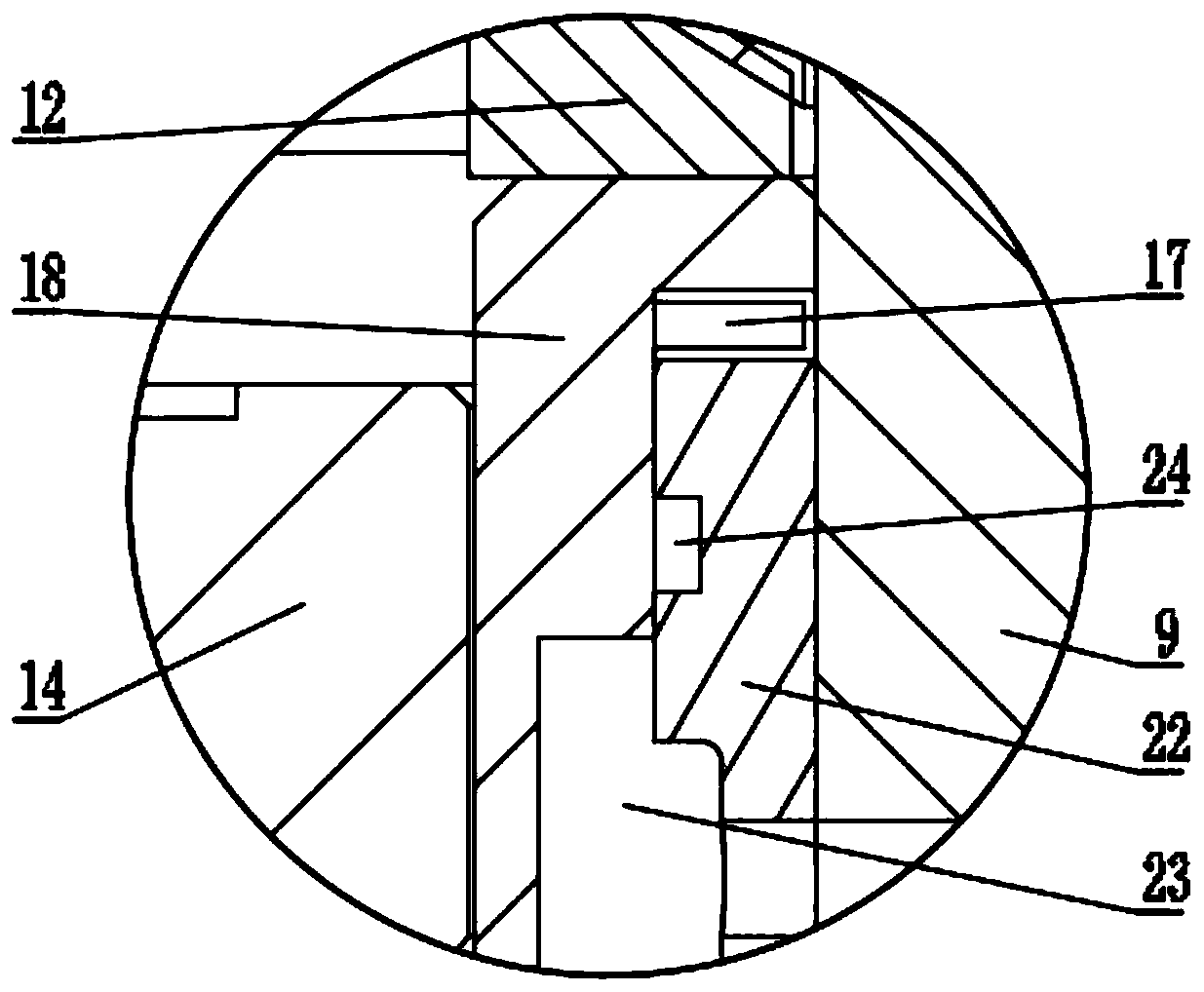

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] Such as Figure 1~5 As shown, a cycloid wheel tooth grinding tool includes a base 1, a through hole is provided in the center of the top surface of the base 1, a supporting plate 19 is provided on the bottom surface of the base 1, and the supporting plate 19 is connected with the base 1 through several screws C15, and the supporting plate 19 The middle liquid expansion mandrel 9 extending into the through hole is arranged on the top, and the liquid filling tank 20 is arranged inside the middle liquid expansion mandrel 9, and the bottom surface of the supporting plate 19 is provided with a plunger 21 threadedly connected with the liquid filling tank 20 through the corresponding groove. , the middle liquid expansion mandrel 9 is fixed with a convex ring 22 through the groove on the base 1, and the middle liquid expansion mandrel 9 above the convex ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com