Plastic pipe fitting processing and recycling device

A technology for recycling plastic pipe fittings, which is applied in plastic recycling, mechanical material recycling, grain processing, etc., can solve the problems of plastic pipe fittings that cannot be crushed, waste of resources, and low efficiency, and achieve improved recycling efficiency, reasonable design, and convenient crushing and recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

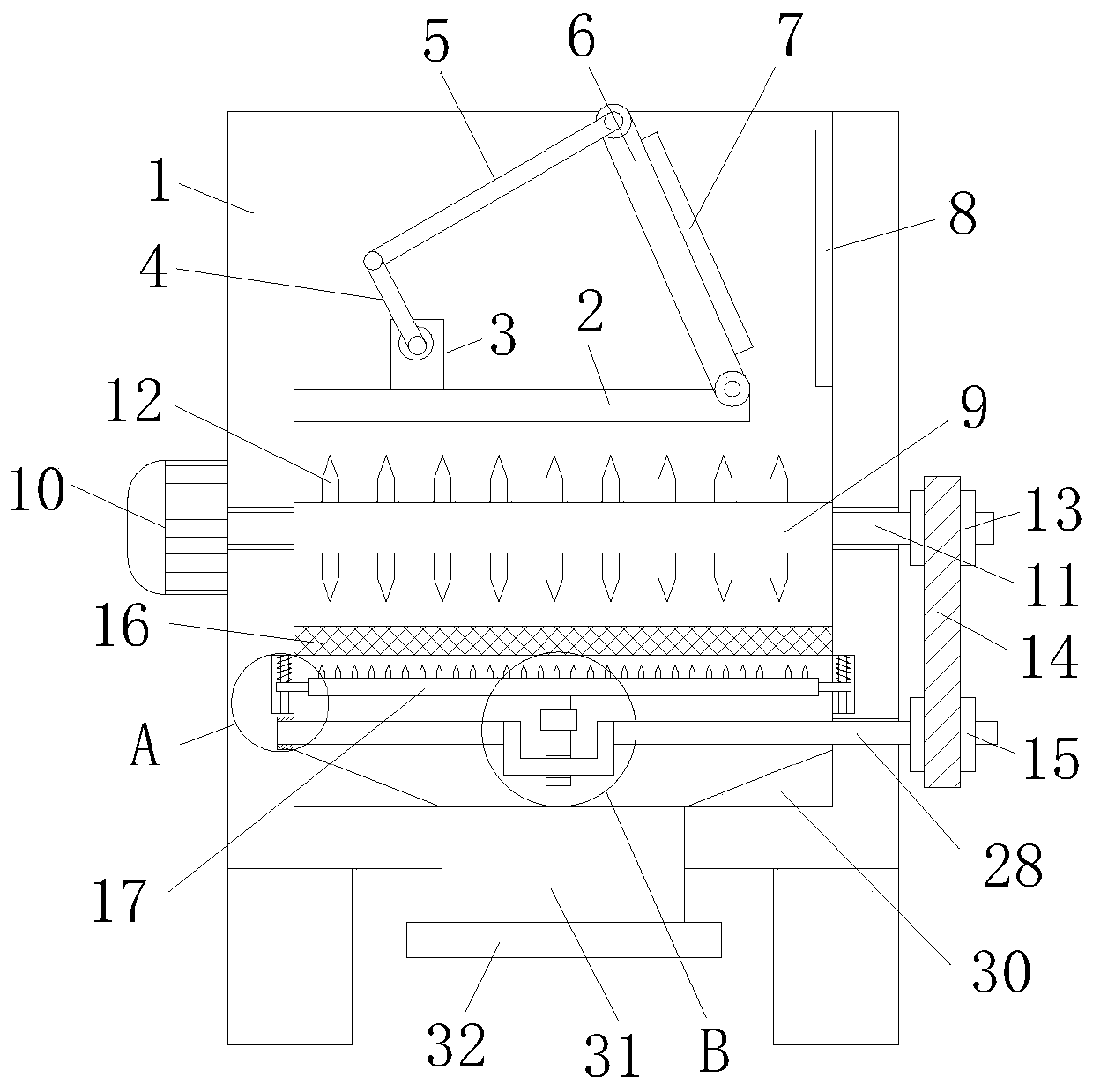

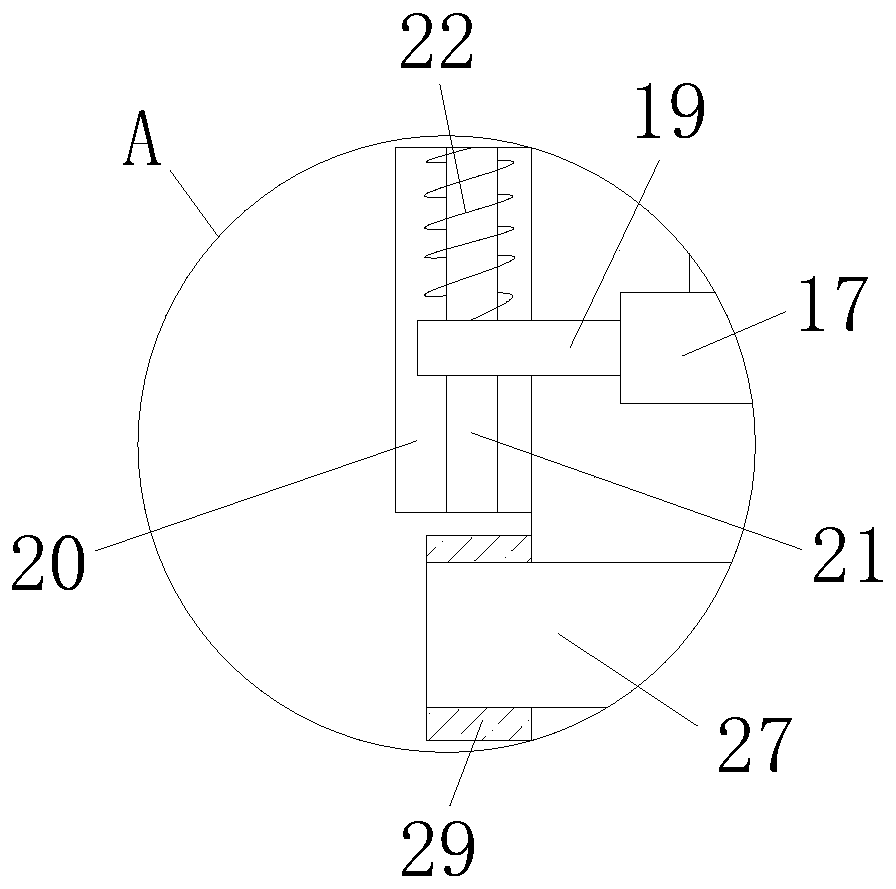

[0028] refer to figure 1 , Figure 3-4 , a processing and recycling device for plastic pipe fittings, comprising a body shell 1, a fixing plate 2 is horizontally fixed on one side of the inner wall of the body shell 1, and a mounting part 3 is fixed on the upper end side of the fixing plate 2, and the outer wall side of the mounting part 3 A first driving motor is installed, and the output end of the first driving motor is connected with a first rotating shaft, and the first rotating shaft runs through the outer wall of the outwardly extending end of the mounting part 3 to rotate and is socketed with a main rotating rod 4, and the main rotating rod 4 is far away from the first rotating shaft One end of the first connecting rod 5 is rotatably connected with the first connecting rod 5, and the end of the first connecting rod 5 away from the main rotating rod 4 is rotatably connected with the second connecting rod 6, and the end of the second connecting rod 6 away from the first ...

Embodiment 2

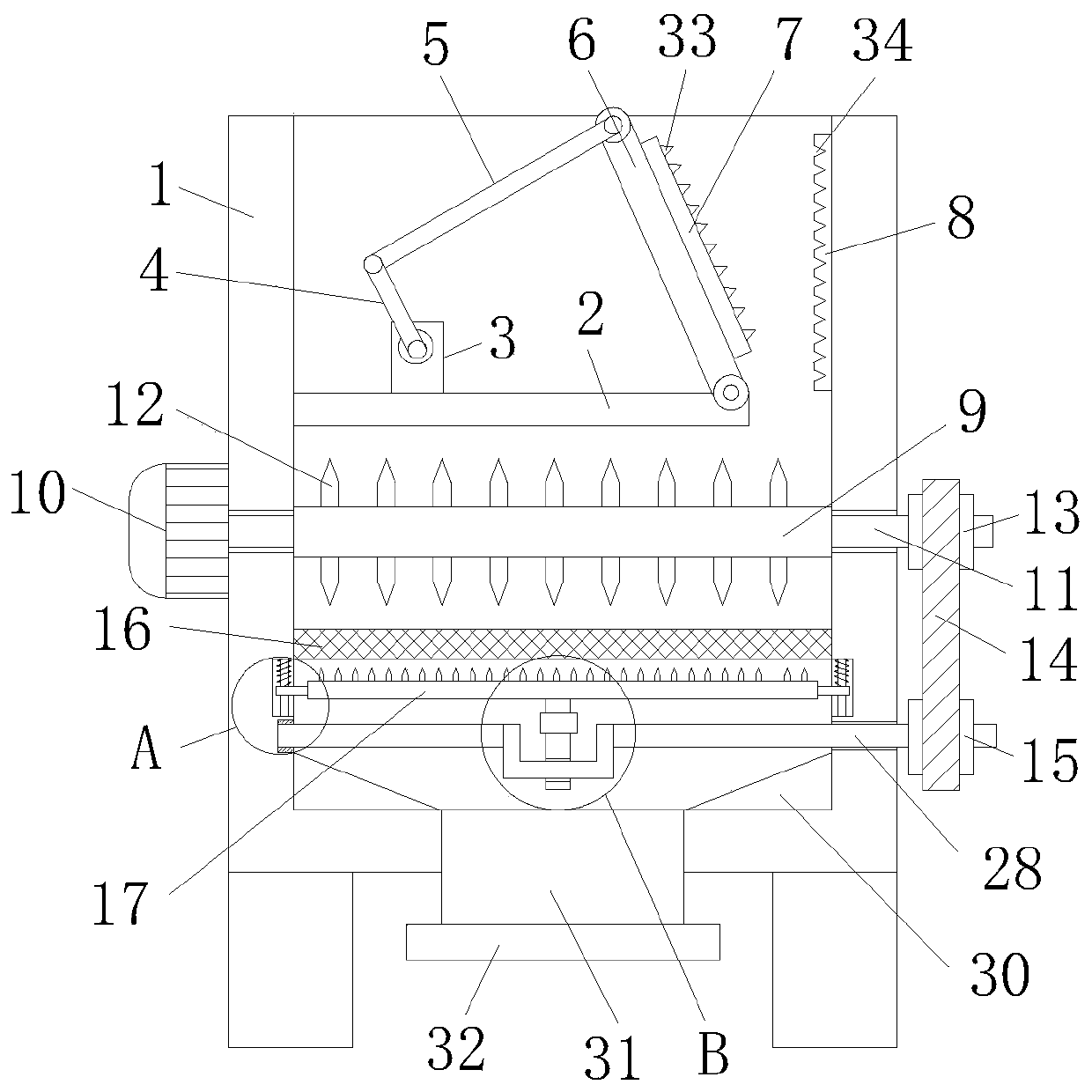

[0036] refer to Figure 2-4 , The difference between this embodiment and Embodiment 1 is that, wherein, the outer wall of the first extruded steel plate 7 is uniformly distributed with several crushing sawtooth 33, and the outer wall of the second extruded steel plate 8 is evenly distributed with several sawtooth grooves 34, and the outer wall of the second extruded steel plate 8 is evenly distributed with several sawtooth grooves 34. 33 and the sawtooth groove 34 cooperate with each other to help the extrusion and crushing of larger plastic pipe fittings.

[0037] Refer to Example 1 for other undescribed structures.

[0038] Working principle: In the present invention, when the plastic pipe fittings to be recycled pass between the first extruded steel plate 7 and the second extruded steel plate 8, the first drive motor is started, and the first drive motor drives the main rotating rod 4 to rotate through the first rotating shaft , when the main rotating rod 4 rotates, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com