Logistics vehicle handling device

A technology of handling device and logistics vehicle, applied in the field of logistics vehicle handling device, can solve the problems of bottom cable, encoder damage, AGV unable to turn, and easily damaged AGV, etc., to achieve the effect of improving efficiency, fast movement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

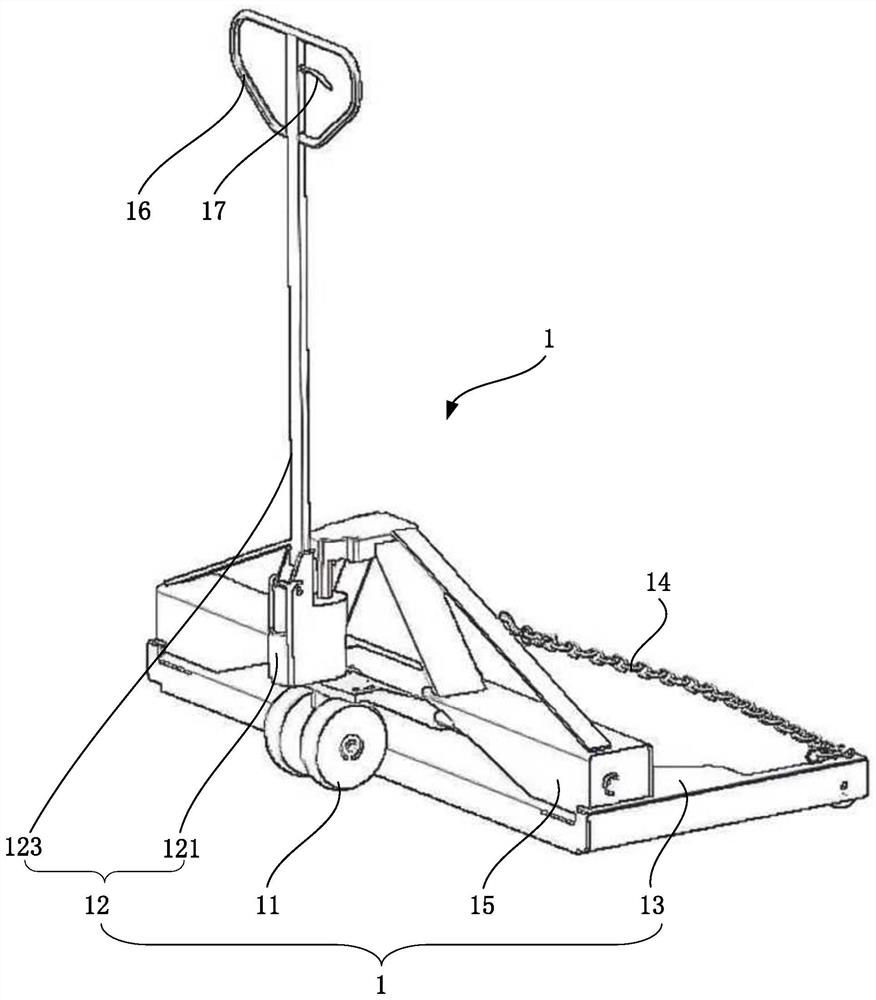

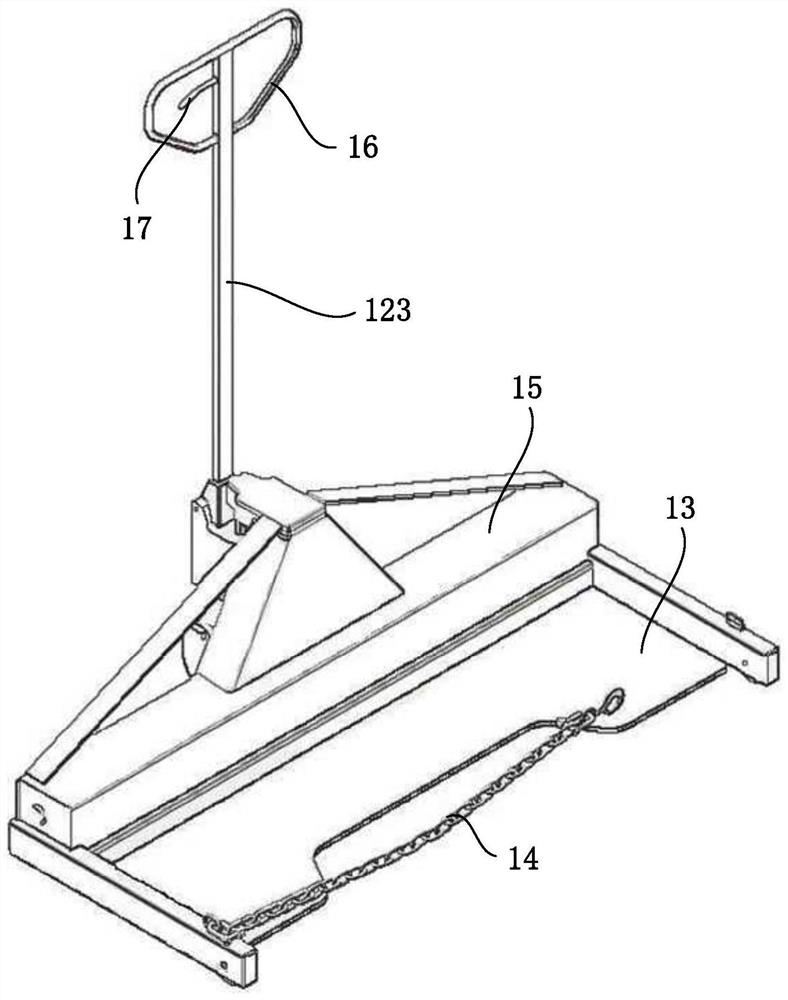

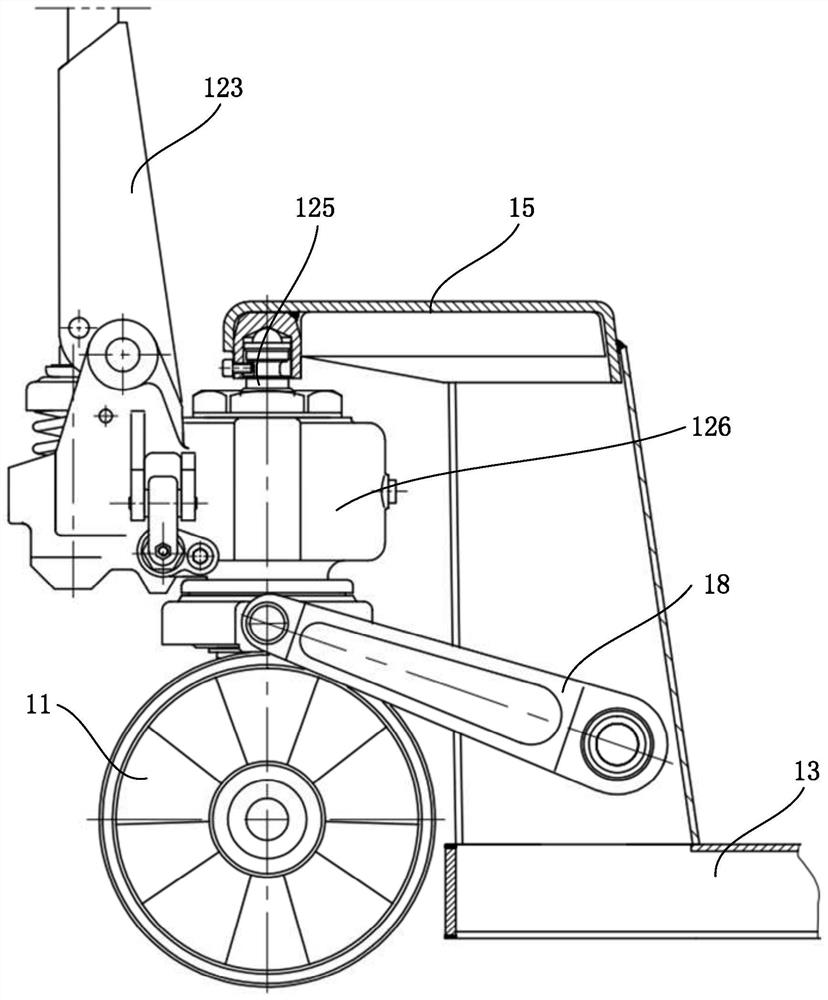

[0045] Combine below Figure 1 to Figure 10 The technical solution provided by the present invention is described in more detail.

[0046] see Figure 1 to Figure 10 , some embodiments of the present invention provide a logistics vehicle handling device, including a first support assembly 1 and a second support assembly 2 .

[0047] The logistics vehicle is, for example, an AGV, which is relatively heavy, for example, it can reach 1.5 tons. AGV is widely used in modern manufacturing enterprises. Its operating speed can reach 100 meters per minute and its transportation capacity can range from several kilograms to several tons. It is the hub of the logistics system. Therefore, it is very important to ensure the normal operation of AGV. When an AGV has a stand-alone software or hardware failure, if it cannot be quickly removed from the walking path, the rest of the AGV in the system will be blocked and tasks will accumulate. In severe cases, material transportation will be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com