Asphalt treatment integrated machine in maltol production

An asphalt processing and integrated machine technology, applied in packaging and other directions, can solve the problems of high labor intensity, difficult asphalt processing, dust pollution and other problems, and achieve the effect of reducing labor intensity, speed and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

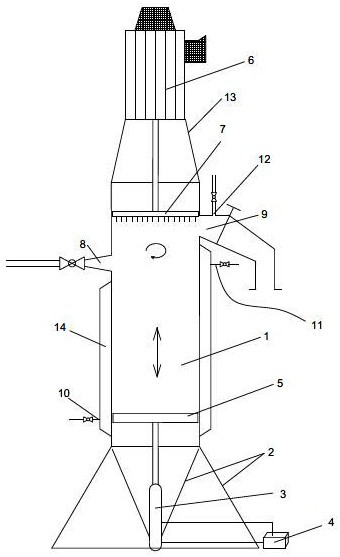

[0016] Such as figure 1 Shown, a kind of asphalt treatment integrated machine in the production of maltol, comprising:

[0017] a. Cylindrical pressure-resistant cooling cylinder 1 (made of stainless steel, inner diameter 120.00cm, height 250.00cm, wall thickness 3.500cm), the upper cylinder of cooling cylinder 1 is provided with asphalt inlet 8 and asphalt outlet 9 (set on the crushing plate 7 5cm from the lower plane) and its corresponding control valve, the outer wall of the cooling cylinder 1 is provided with a cooling jacket 14, and the cooling jacket 14 is provided with a cooling liquid (water) inlet 10, an outlet 11 and its corresponding control valve. A vent pipe 12 and a vent valve are provided on the pipeline of the asphalt outlet 9;

[0018] b. The lower part of the cooling cylinder 1 is connected to the metal support base 2, and the hydraulic cylinder 3 is connected to the metal support base 2. The rod shaft of the hydraulic cylinder 3 goes deep into the cooling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com