A device and method for co-conversion of heavy low-quality oil and coal

A low-quality oil, co-conversion technology, applied in the coal chemical industry, can solve the problems of small amount of petroleum coke, difficult to realize the integrated reaction of heavy and low-quality oil pyrolysis gasification, easy coking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

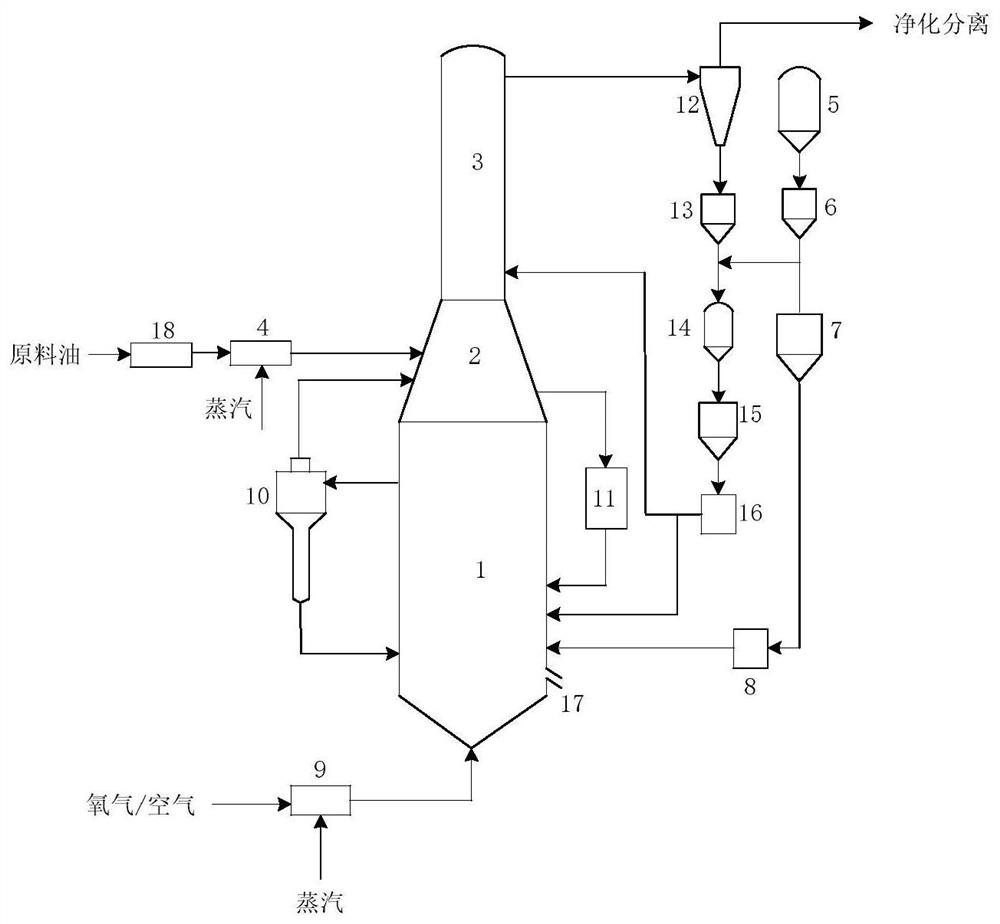

[0029] see figure 1 , the device of the present invention includes a feeding unit, a gasification unit, a cracking unit, and a powder coke returning unit;

[0030] The feeding unit is used to complete the stable transportation of raw oil and pulverized coal. The raw oil is heavy and inferior oil. The feeding unit includes a raw oil feeding system and a pulverized coal feeding system: the raw oil feeding system includes Raw oil preheater 18, the inlet of the raw oil preheater 18 is connected with the raw material oil, the raw material oil is heavy and low-quality oil, including heavy oil with residual carbon>20%, super heavy oil, oil sand bitumen, vacuum residue, For deoiling asphalt, the outlet of the feed oil preheater 18 is connected to the inlet of the high-efficiency atomizer 4, and the feed oil preheated by the feed oil preheate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com