A kind of solid-state fermented persimmon vinegar and preparation method thereof

A technology of solid-state fermentation and persimmon cakes, applied in the field of fermentation, can solve the problems of fermentation failure, low production efficiency, and extensive production process that are easily contaminated with miscellaneous bacteria, and achieve the effects of increasing microbial diversity, extending the industrial chain, and novel flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

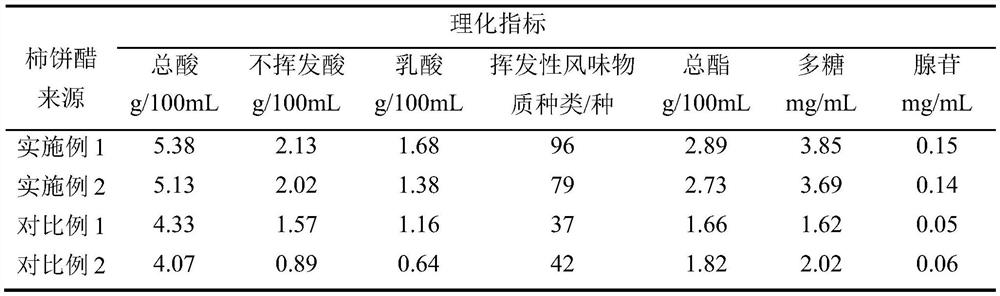

Embodiment 1

[0030] (1) Preparation of persimmon enzymatic hydrolyzate: mix persimmon and water at a mass ratio of 1:6, after beating, add pectinase and cellulase with 0.1% of the mass of persimmon, and control the temperature at 55°C after mixing evenly , enzymatic hydrolysis for 3 hours to obtain persimmon enzymatic hydrolyzate.

[0031] (2) Preparation of rice saccharification liquid: mix rice flour and water at a mass ratio of 1:5, gelatinize at a controlled temperature of 105°C for 0.5h; control the temperature at 96°C, add α-amylase of 0.25% of the mass of rice flour , liquefied for 2 hours, then raised the temperature to 110°C for 15 minutes to inactivate the enzyme; controlled the temperature at 60°C, added 0.04% rice mass glucoamylase, and saccharified for 1.5 hours to obtain a rice saccharification solution;

[0032] (3) Addition of medicinal edible fungi: mix persimmon enzymatic hydrolysis solution and rice saccharification solution at a mass ratio of 1:1, heat up to 110°C for 1...

Embodiment 2

[0041] (1) Preparation of persimmon enzymatic hydrolyzate: mix persimmon and water at a mass ratio of 1:6, after beating, add pectinase and cellulase with 0.15% of the mass of persimmon, and control the temperature at 60°C after mixing evenly , enzymatically hydrolyzed for 2h to obtain persimmon enzymatic hydrolyzate.

[0042] (2) Preparation of rice saccharification solution: mix rice flour and water at a mass ratio of 1:5, gelatinize at a temperature of 95°C for 1 hour; Liquefy for 1.5 hours, then raise the temperature to 110°C for 20 minutes to inactivate the enzyme; control the temperature at 62°C, add 0.05% rice mass glucoamylase, and saccharify for 2 hours to obtain rice saccharification liquid;

[0043] (3) Addition of medicinal edible fungi: mix persimmon enzymatic hydrolysis solution and rice saccharification solution at a mass ratio of 1:1, heat up to 110°C for 15 minutes to inactivate the enzyme; cool the mixed mash to below 30°C, and inoculate cicada sticks For Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com