Novel waxing type workbox for textile industry

A technology for textile industry and needle and thread box, which is applied in the field of new waxing type needle and thread box in the textile industry, can solve the problems of not realizing the process of waxing on the textile thread and needle threading process, reducing work efficiency, etc., and achieves simple structure, convenient operation, and improved work efficiency. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

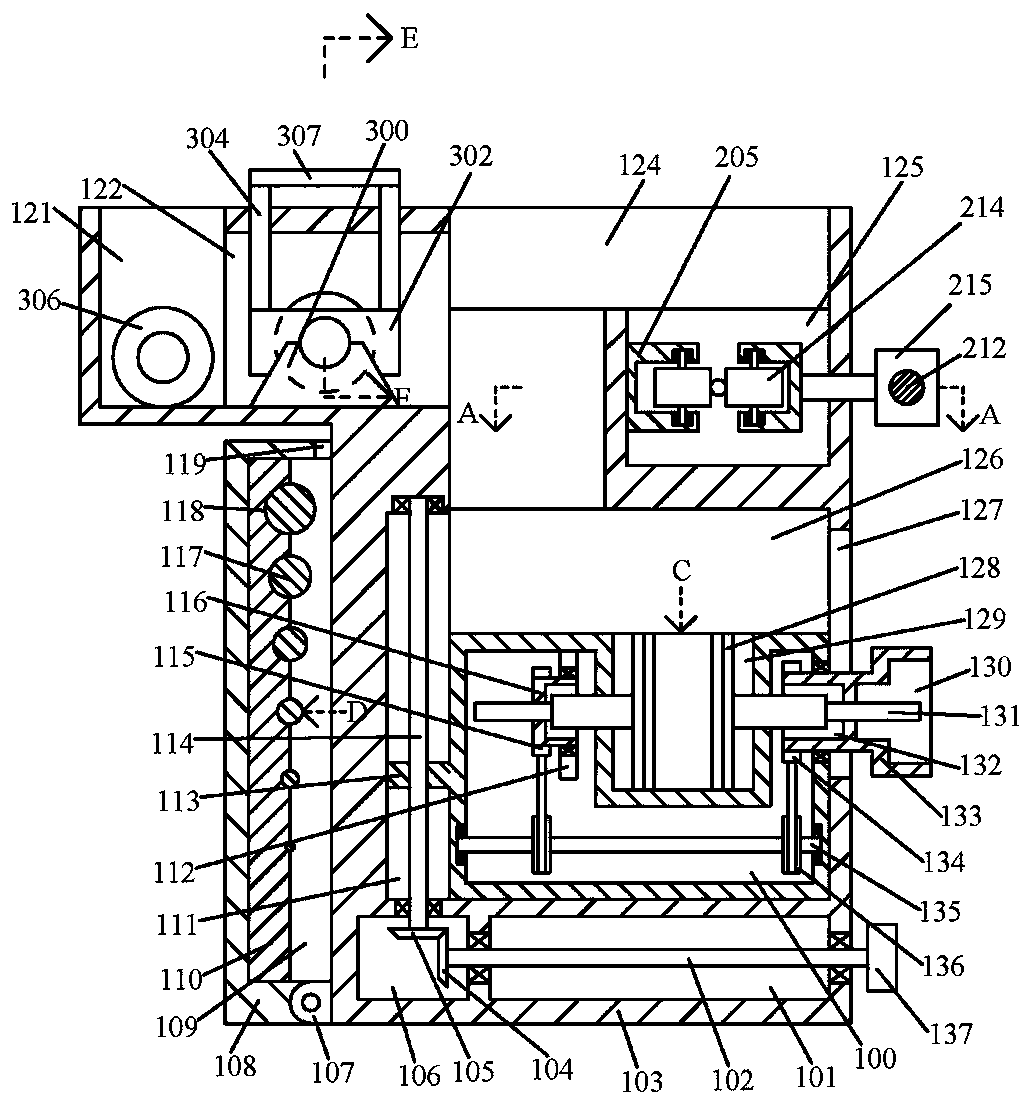

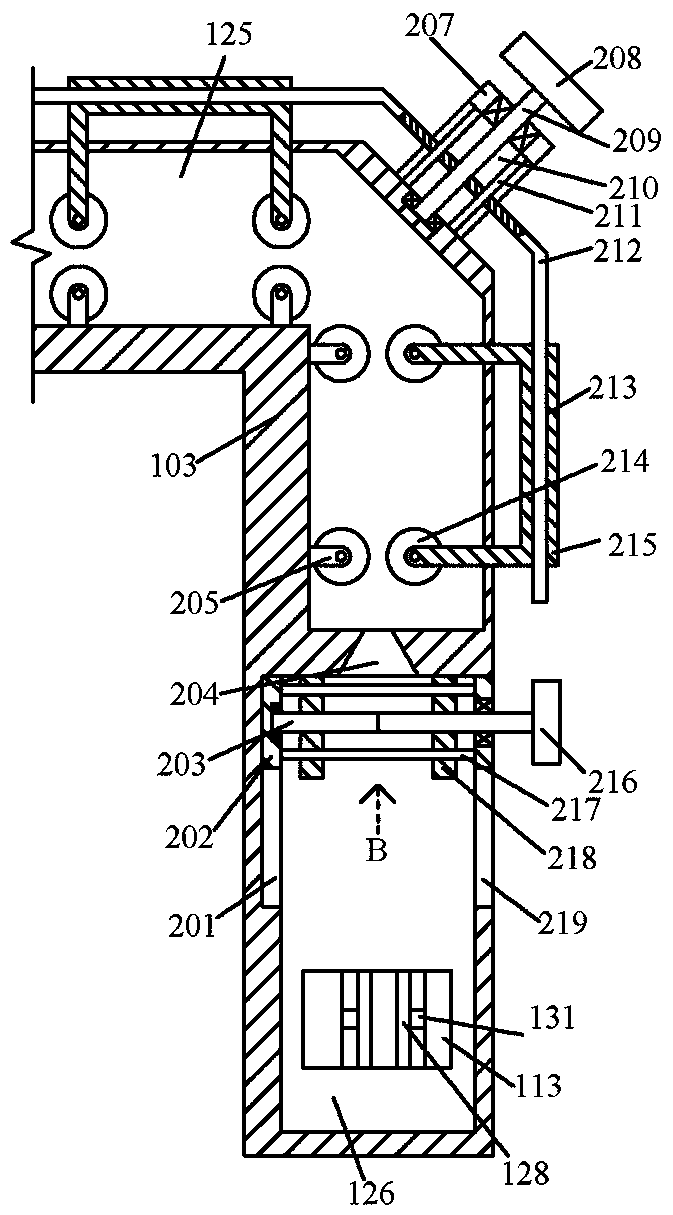

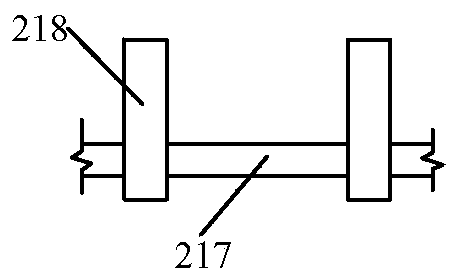

[0022] Combine below Figure 1-7 The present invention will be described in detail.

[0023] refer to Figure 1-7 , according to an embodiment of the present invention, a new type of waxing sewing box for the textile industry, including a box body 103, the box body 103 is fixed with a lower side chamber 101, and the left side of the lower side chamber 101 is provided with a box located in the box body 103. The gear cavity 106, the depth of the gear cavity 106 is 40mm, the upper side of the lower cavity 101 is provided with a through cavity 126 in the box body 103, the depth of the through cavity 126 is 300mm~350mm, and the right end wall of the through cavity 126 is connected with a chute 127, the chute 127 communicates with the external space, the depth of the chute 127 is 80mm, the left end wall of the through cavity 126 is connected with a sliding cavity 111, and the right angle cavity 125 located in the box body 103 is arranged above the through cavity 126, and the right ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com