Firewood combustion furnace with inclined flue and descending smoke

A flue and furnace technology, which is applied in household furnaces/stoves, solid heating fuels, household heating, etc., can solve problems such as large emissions, unfavorable environmental protection, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

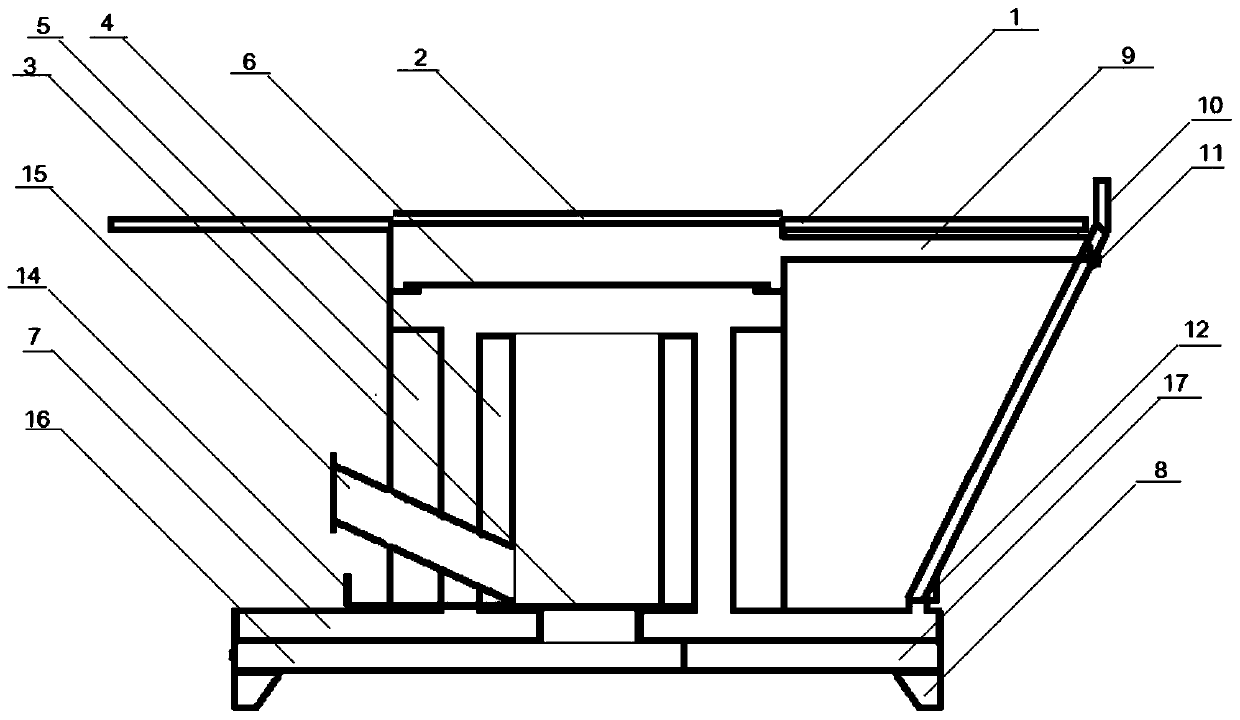

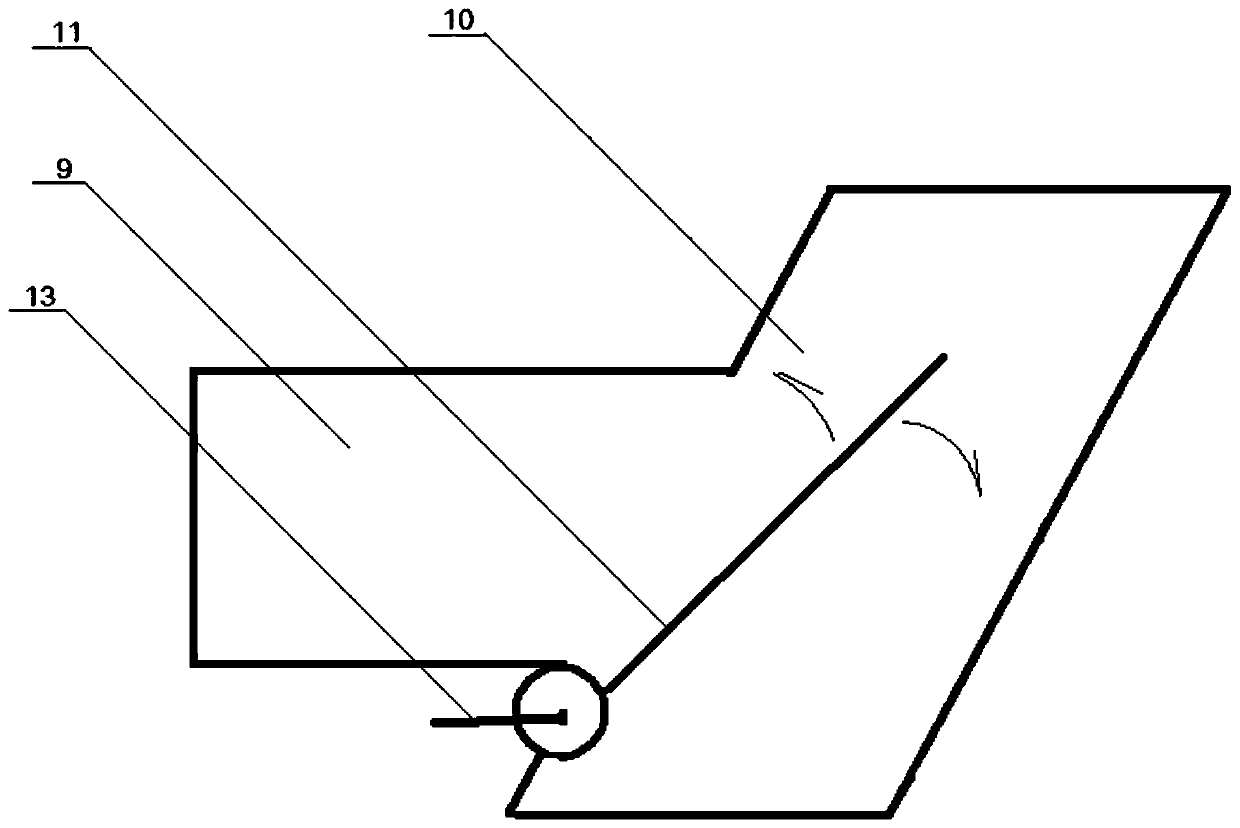

Embodiment 1

[0019] Embodiment 1: A firewood burning furnace in which the flue gas of an inclined flue can go down, the furnace panel 1 is provided with a furnace cover 2 which is convenient to take off, and a hollow tempering box area is provided under the furnace cover 2 of the furnace panel 1, There is an inner furnace core 4 and an outer furnace core 5 set together under the tempering box area, and a hollow interlayer bottom interlayer 7 is provided under the inner furnace core 4 and the outer furnace core 5; the tempering layer under the furnace panel 1 In the middle of the box area, there is a fire cover plate 6 that divides it into upper and lower parts. On the upper side of the tempering box area, the top cover fire plate 6 is provided with a horizontal smoke pipe 9 that can discharge exhaust gas outward. The bottom of the furnace panel 1 is connected to the inclined flue 10, and the connection between the horizontal smoke pipe 9 and the inclined flue 10 is provided with a controlla...

Embodiment 2

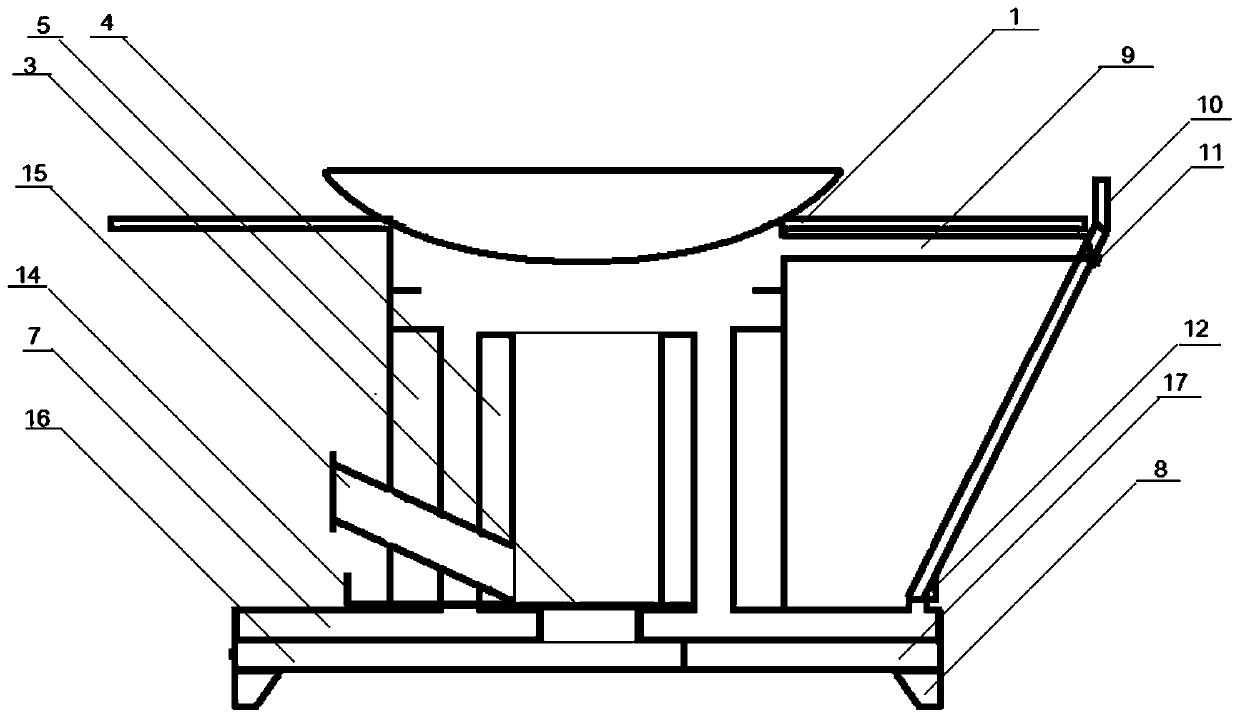

[0020] Embodiment 2: A firewood burning furnace in which flue gas from an inclined flue can go down, a furnace cover 2 that is conveniently removed is provided on the furnace panel 1, and a hollow tempering box area is provided under the furnace cover 2 of the furnace panel 1. There is an inner furnace core 4 and an outer furnace core 5 set together under the tempering box area, and a hollow interlayer bottom interlayer 7 is provided under the inner furnace core 4 and the outer furnace core 5; the tempering layer under the furnace panel 1 In the middle of the box area, there is a fire cover plate 6 that divides it into upper and lower parts. On the upper side of the tempering box area, the top cover fire plate 6 is provided with a horizontal smoke pipe 9 that can discharge exhaust gas outward. The bottom of the furnace panel 1 is connected to the inclined flue 10, and the connection between the horizontal smoke pipe 9 and the inclined flue 10 is provided with a controllable clo...

Embodiment 3

[0021] Embodiment 3: A firewood burning furnace in which the flue gas of an inclined flue can go downward. The furnace panel 1 is provided with a furnace cover 2 for easy removal, and a hollow tempering box area is provided under the furnace cover 2 of the furnace panel 1. There is an inner furnace core 4 and an outer furnace core 5 set together under the tempering box area, and a hollow interlayer bottom interlayer 7 is provided under the inner furnace core 4 and the outer furnace core 5; the tempering layer under the furnace panel 1 In the middle of the box area, there is a fire cover plate 6 that divides it into upper and lower parts. On the upper side of the tempering box area, the top cover fire plate 6 is provided with a horizontal smoke pipe 9 that can discharge exhaust gas outward. The bottom of the furnace panel 1 is connected to the inclined flue 10, and the connection between the horizontal smoke pipe 9 and the inclined flue 10 is provided with a controllable closing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap