A Low Phase Noise Microwave Frequency Comb Generator with Adjustable Comb Distance

A technology with low phase noise and microwave frequency, applied in the direction of solid-state lasers, etc., can solve the problems of fixed comb distance and large phase noise, and achieve the effect of increasing frequency components, large frequency multiplication factor, and increasing the number of photoelectric oscillation loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

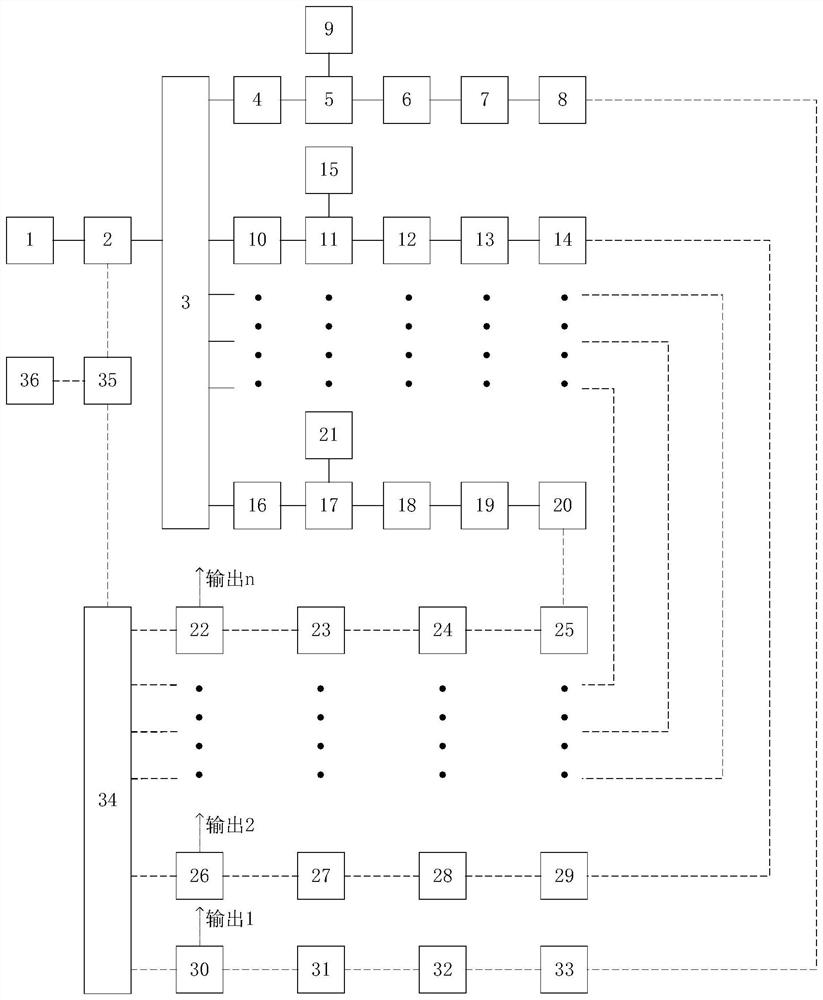

[0021] Example: using figure 1 The shown microwave frequency comb generator generates a low phase noise microwave frequency comb with adjustable comb distance. The specific process is as follows:

[0022] Step 1: adjust the bias voltage of the intensity modulator 2, so that the microwave signal generated by the microwave source 36 modulates the continuous optical signal generated by the laser 1 to form sidebands of each order of the optical signal, and adjust the three polarization controllers 4, 10 , 16; match the corresponding DFB laser.

[0023] Step 2: Adjust the parameters of the three DFB lasers 9, 15, and 21 drive units, inject and lock the sidebands of the corresponding optical signals to increase their optical power, and pass through three optical delay lines 6, 12, 18 and three respectively After the long optical fibers 7, 13, 19, they enter three corresponding photodetectors 8, 14, 20 to form respective beat frequency signals.

[0024] Step 3: The generated beat f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com